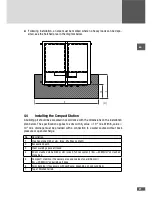

20

The Compact Station must not be lifted with a forklift truck engaging in the area of the

cable pass-through points.

4.2

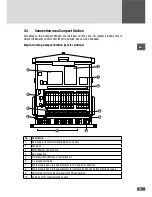

Checking the delivery

The Compact Station is supplied including the following items:

Quantity

Description

6

System cover

∅

150

1

System cover

∅

90

1

Protection conduit (only slave stations)

1

Instruction manual

4.3

Selecting the installation location

The ambient conditions are specified in the specifications, see 13 Specifications.

Location and installation conditions

■

■

Maintain the maximum installation depth (see symbol on the side of the Compact

Station and Section 2.2)

■

■

Maintain an unobstructed area of 1 meter around the Compact Station for mainte-

nance work.

■

■

The floor must be sufficiently load-bearing and smooth.

Note

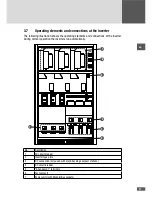

The heat sinks of the inverters are cooled by fans. The ambient air is sucked

in at the bottom of the inverter through the ventilation grilles and is blown out

through the ventilation grilles at the top of the inverter.

■

■

The ambient air around the Compact Station must be free from salt and ammonium

vapors.

■

■

The installation location must meet the requirements regarding the electromagnetic

immunity and interference emission.

■

■

Due to the noise generated, the Compact Station should not be installed near living

and working areas.