Subject to change | © 2019 SOLARWATT GmbH | AZ-TM-PMS-1339 | Rev 001 | Version: 12/2019

Page 28

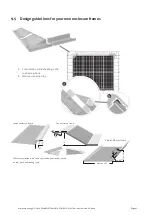

6.6 Cable ducting through the roof

Piping bushings and cable bushings are to be attached

above or to the side of the area covered with the Eas-

yIn modules. A cable bushing between the track supports

is also possible. However only one cable (max. 6 mm²

cross-section) can be bushed and the distance to the oth-

er cables must be at least 10 cm.

In addition, no mounting parts must be located within or

below the area covered with the EasyIn modules, unless

these integrated parts are not located in the water-bear-

ing layer.

For the cable bushing diff erent variants are possible.

Common variants are shown below:

Cable bushing on the roof ridge side of the system

above the sarking membrane through the ventilation

gap on the roof ridge

●

Use of the ventilation gap on the roof ridge is pos-

sible

(see Figure 38)

Cable bushing through the inward and outward

projecting conduit in the area of the under-membrane,

especially in the case of a converted attic

●

Rainproof and windproof bonding (system adhesive

tapes) with the sarking membrane or under-mem-

brane.

●

Pipe penetrates heat insulation layer on the room

side

●

and is air-sealed with a system adhesive tape system

to the vapor barrier.

●

Closure of the conduit on the room-side and roof-

side after completion of the cable bushing work.

(see Figure 39)

Cable bushing between the track supports

●

The cable is bushed inwards through the track sup-

ports which overlap at least 10 cm.

●

Bushing of a max. one cable which must have a cable

cross-section of a maximum 6 mm².

●

If several cables are to be bushed inwards, then the

distance between the cable bushing points must be

at least 10 cm.

(see Figure 40)

Figure 38

A Covering strip

D Cable

B Ventilation gap

E Modules

C Sarking membrane

A

B

C

D

E

Figure 39

A Under-membrane

B Conduit

C Flexible system adhesive tape

Connection of the steam brake/air-tight layer

room side as shown.

A

B

C

Figure 40

10

cm