•

The glass-glass modules should be clam-

ped into position on the long side of mo-

dules as a minimum. You should select a

glass edge cover which ensures that gla-

zing is secured in place for the long term.

•

Do not use any glues, adhesive tape, or

seals to mount the laminates which come

into contact with the embedded material

unless explicitly allowed by SOLARWATT.

•

Make sure that the laminate edges do not

lie in accumulated water and are always

able to dry after exposure to rain or other

water.

Under mechanical load, no contact between solar glass and hard materials (eg. metal,

glass) may occur.

NOTE

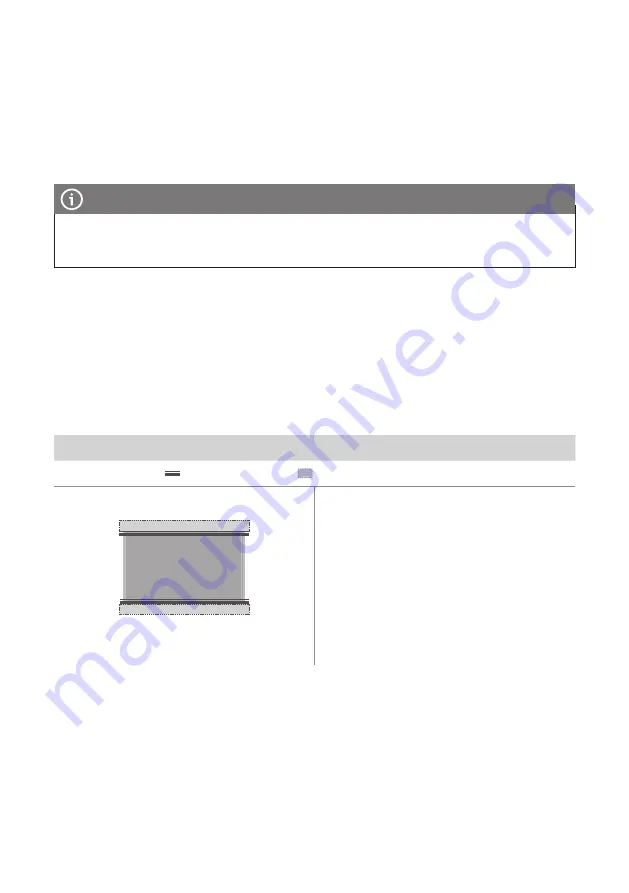

The following table shows:

• the way of fastening

• the areas approved for fastening

• the maximum recommended pressure load on the modules*

* The specifi ed recommended loads contain a safety factor of 1.5 in accordance with the IEC 61215

standard and apply to fl at and sloping roofs with unobstructed snow slipping. The maximum given

load is valid only for on-roof application.

Fixing by long side clamping

areas approved for fastening

substructure

Max. recommended pressure load to the module: 5,400 N/m²

Electrical connection and grounding

SOLARWATT solar modules are equipped at the

factory with high-quality solar cables and rever-

se-polarity protected, shock proof plug connec-

tors. The connection of the string line has to be

done with identical connectors manufacture

and type as to the module connecting cable. To

be able to ensure this the module connector at

the beginning and the end of the string may be

removed and replaced (More information in the

download area at www.solarwatt.com). The al-

lowed cross-section and outer-diameter of the

cable and instruction of the manufacturer have

SUBJECT TO CHANGE | © 2019 SOLARWATT GMBH | AZ-TM-PMS-1703 | REV 006 | STATUS: 08/2019 | PAGE 5