2

/

3

DESCRIPTION

SP-1011DLR Soldering & Reworking Station is suitable for soldering and desoldering all type of surface mounted IC and prevents any

damage to the PCB or components. This tool is used in the fields of electronic research, teaching and production, especially in the

repairing and reworking on the electronic appliances and communication equipments.

TECHNICAL SPECIFICATION

STATION

SOLDER

HOT AIR SMD REWORK

INPUT VOLTAGE

220-2400VAC

VOLTAGE

24VAC

VOLTAGE

110-130VAC

220-2400VAC

POWER

CONSUMPION

60W+320W

POWER

60W

HEAT UP RATING 130W

CAPACITY

24L/MIN(MAX)

MAIN FUSE

3A

TEMPERTURE

160

℃

-480

℃

POWER

320W

AIR PUMP

DIAPHRAGM

HEATING ELEMENT

CERAMIC HEATER

TEMPERAT.

160

℃

-480

℃

OPERATING INSTRUCTIONS

Caution

:

Make sure that the four screws which are used to fasten the Diaphragm pump are removed from the control system

before use. Otherwise serious damages may be caused to the user and the system.

1.

Place the soldering iron and the hot air gun in the holder separately. Then connect the plug to the receptacle on the station and

turn clockwise to tighten the plug nut. Check that the power supply is corresponding to the specification on the type plate and

the power switch is on the “OFF” position. Connect the control unit to the power supply and switch on the power and then

switch on the soldering iron or the SMD rework unit at the power switch. Then a self-test is carried out in which all display

elements are switched on briefly. The electronic system then switches on automatically to the set temperature and displays this

value.

Caution:

When the power supply is connected (while the power switch is on the “OFF” position), the soldering iron and the hot air

gun will be on the pre-heating status, and the hot air gun will blow air automatically for one minute.

2

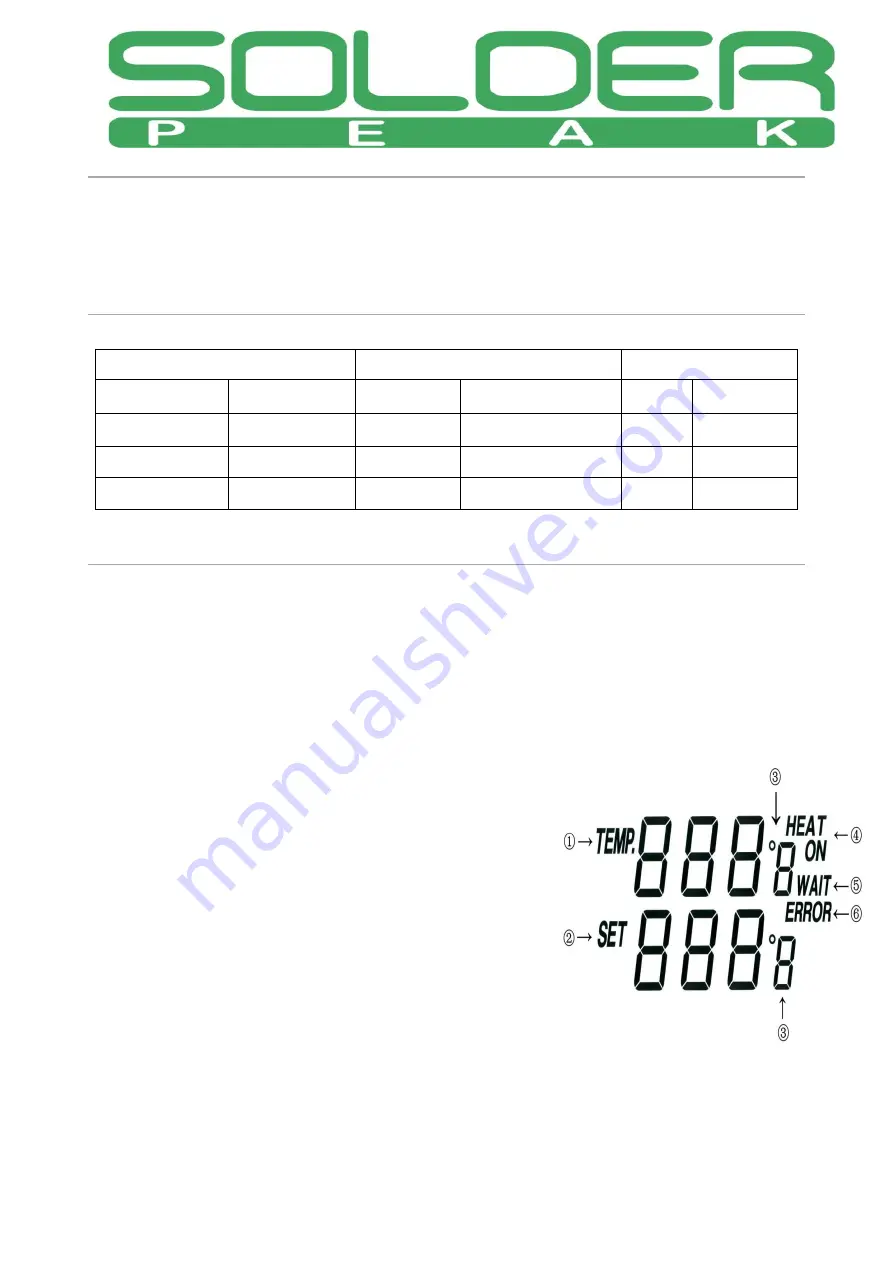

The display and temperature setting

The digital display:

①

shows the actual temperature of the soldering tip or the nozzle of the hot air

gun.

②

shows the setting temperature. Pressing the “UP” or “DOWN” button can switch

the digital display to the set point display. The set-point can be changed for ±1

℃

by

tapping the “UP” or “DOWN” button. Pressing the button will change the

set-point quickly. The digital display will return automatically to the actual value

and the iron will reach to the setting temperature quickly.

③℃

/

℉

display: Switching the temperature display from

℃

to

℉

by pressing

the “

℃

/

℉

”button and then the electronic system will display the actual

temperature

①

and setting temperature

②

in

℉

, and vice versa.

④

When the actual temperature on the soldering tip of the nozzle is less than the

set-point, “HEAT ON” will display and make the soldering tip or the nozzle

heating up.

⑤

When the absolute offset is more than ±10

℃

between the actual temperature

and the set-point on the soldering tip or the nozzle, “WAIT” will display. It means that the temperature electronic control

system is not in the stable situation, we should wait a moment to let the “WAIT” disappear.

⑥

When “ERROR” display, there may be a trouble on the system, or the soldering iron is not connected to the control system

correctly.

Summary of Contents for SP-1011DLR

Page 1: ...1 3 SP 1011DLR...