ns. rif:

SI003-033

GB

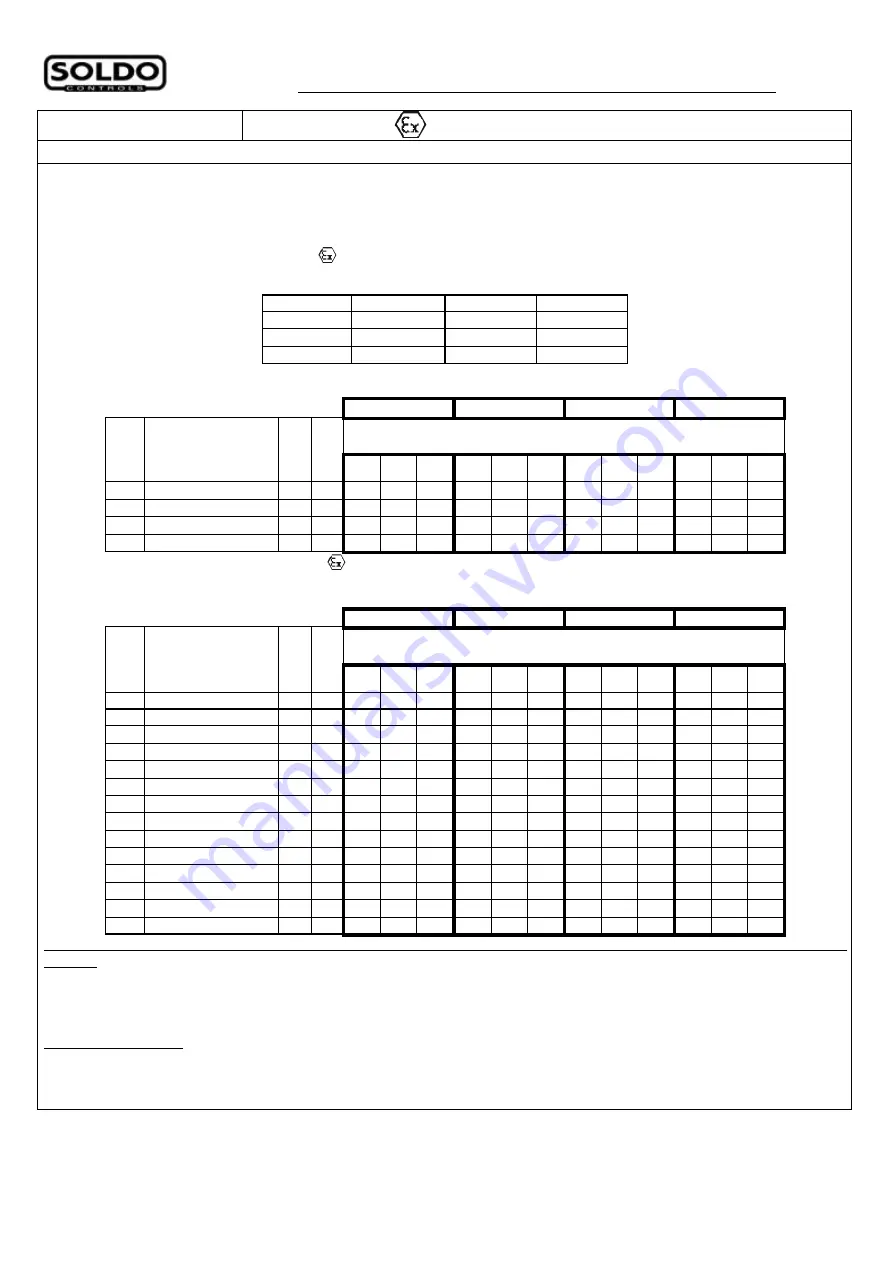

Safety instruction to hazardous area installation

Model numbers covered: limit switch box series SI_ _ _ _ _ _-_ ( _ indicates options in housing configuration, switches,

switches quantity, terminal strip, box colour, cable entries).

The following instructions apply to equipment covered by ATEX certificate number

03ATEX 135107X

1)

The SI limit switch box series may be used in an hazardous area with flammable gases, vapours, dust and mist, group

IIC, protection mode EEx ia with the following temperature classes T4,T5,T6.

1a) Device category 2G, EX identification

II 2 G EEx ia IIC T6

Evaluation and supply circuit Type Intrinsic Safety Max value

Type 1

Type 2

Type 3

Type 4

U

i

i

i

=

=

=

16 V

U

i

i

i

=

=

=

16 V

U

i

i

i

=

=

=

16 V

U

i

i

i

=

=

=

16 V

I

i

= 25 mA

I

i

= 25 mA

I

i

= 52 mA

I

i

= 76 mA

P

i

= 34 mW P

i

= 64 mW P

i

= 169 mW P

i

= 242 mW

The assignment of the type of the connected circuit to the maximum permissible temperature and the temperature class

as well as the effective internal reactances for the individual types of limit switch boxes are shown in the following table:

Type 1

Type 2

Type 3

Type 4

Maximum permissibile ambient temperature

in C° for application in temperature class

Soldo

Code

P +F

switches code

C

i

i

i

(nF)

L

i

i

i

(?H)

T6

T5

T4

T6

T5

T4

T6

T5

T4

T6

T5

T4

SI_20

NJ4-12GK-N

45 50

73

88 100 69

84 100 51

66 80

39

54 61

SI_24

NJ2-12GK-N

45 50

73

88 100 69

84 100 51

66 80

39

54 61

SI_59 NCB2-12GK35-N0 90 100 76

91 100 73

88 100 62

77 81

54

63 63

SI_61 NCN4-12GK35-N0 95 100 73

88 100 69

84 100 51

66 80

39

54 61

1b) Device category 2GD, EX identification

II 2 G/D EEx ia IIC T6

The assignment of the type of the connected circuit to the maximum permissible temperature and the temperature class

as well as the effective internal reactances for the individual types of limit switch boxes are shown in the following table:

Type 1

Type 2

Type 3

Type 4

Maximum permissibile ambient temperature

in C° for application in temperature class

Soldo

Code

P +F

switches code

C

i

i

i

(nF)

L

i

i

i

(?H)

T6

T5

T4

T6

T5

T4

T6

T5

T4

T6

T5

T4

SI_28

NJ2-11N-G

30 50

76

91 100 73

88 100 62

77 81

54

63 63

SI_30 NCB2-12GM35-N0 90 100 76

91 100 73

88 100 62

77 81

54

63 63

SI_36

NJ5-11-N-G

45 50

72

87 100 65

80 100 42

57 82

26

41 63

SI_37 NCN4-12GM35-N0 95 100 76

91 100 73

88 100 62

77 81

54

63 63

SI_39

NJ2-12GK-SN

50 150 73

88 100 69

84 100 51

66 80

39

54 61

SI_50

NJ2-11SN-G

50 150 76

91 100 73

88 100 62

77 81

54

63 63

SI_60

SJ-3.5-N

50 250 73

88 100 66

81 100 45

60 89

30

45 74

SI_62

SJ-3.5-SN

30 100 73

88 100 66

81 100 45

60 89

30

45 74

SI_63

SJ-3.5-S1N

30 100 73

88 100 66

81 100 45

60 89

30

45 74

SI_68

NJ5-11-N

45 50

72

87 100 65

80 100 42

57 82

26

41 63

SI_69

NJ2-11-N

45 50

73

88 100 66

81 100 45

60 89

30

45 74

SI_70

NJ2-V3-N

40 50

73

88 100 66

81 100 45

60 89

30

45 74

SI_84

NJ2-11-SN

50 150 73

88 100 66

81 100 45

60 89

30

45 74

SI_86

NJ4-12GK-SN

70 150 73

88 100 69

84 100 51

66 80

39

54 61

Cross the temperature rating shown with the limit switch box rating shown in limit switch box installation & operating

manual.

2)

Suitably trained personnel shall carry out installation in accordance with applicable code of practice

3)

The user should not repair this equipment.

4)

If the equipment is likely to come into contact with aggressive substances, it is responsibility of the user to take suitable

precautions that prevent it from being adversely affected, thus ensuring that the type of protection is not compromised.

Agressive substances – es. Acidic liquids or gases that may attack the switch box housing.

5)

The following precaution must be observed:

The metallic alloy used for the enclosure, in the event of a rare accident, could cause ignition sources due to impact or

friction (sparks may occur). This shall be considered when the box is installed in group II category 2 G/D areas.

Pag. 3 of 22

Summary of Contents for SIF Series

Page 14: ...Pag 14 of 22...

Page 15: ...Pag 15 of 22...

Page 16: ...Pag 16 of 22...

Page 17: ...Pag 17 of 22...

Page 18: ...Pag 18 of 22...

Page 19: ...Pag 19 of 22...

Page 20: ...Pag 20 of 22...

Page 21: ...Pag 21 of 22...

Page 22: ...Pag 22 of 22...