Dyaco Canada Inc. 2013

10

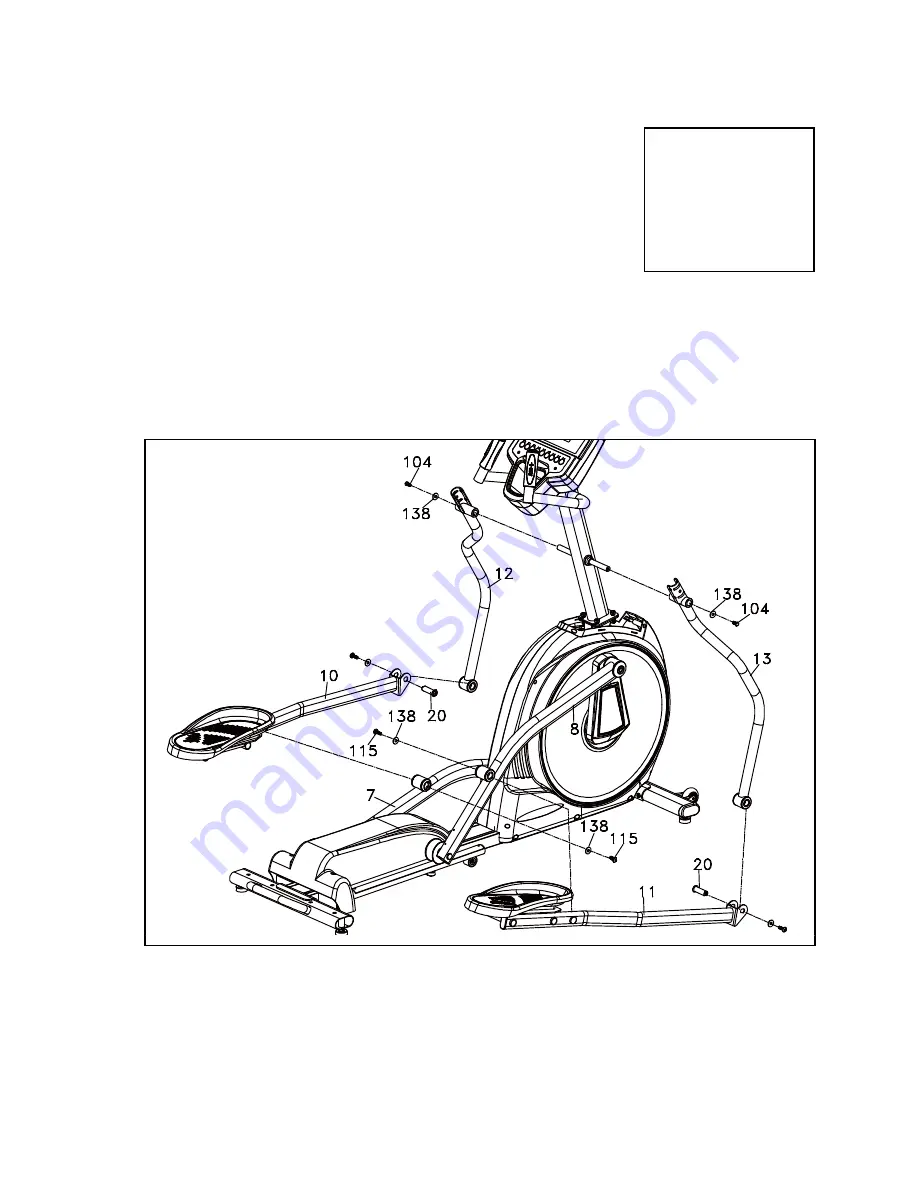

#104

. 5/16” x 15mm

Hex Head Bolt (2 pcs)

#115

. 5/16” x 15mm

Button Head Socket Bolt

(2 pcs)

#138

. Ø8.5 × 26mm× 2T

Flat Washer (4 pcs)

2

LOWER

SWING ARMS

HARDWARE STEP 2

1.

Attach the Lower Swing Arms

(L)

and

(R)

,

(12)

and

(13)

, on each side of

Console Mast shaft and secure with two Hex Head Bolts

(104)

and two Flat

Washers (

138

) by using the Wrench (

152

).

2.

Insert the shaft of the left Connecting Arm (

10

) through the bushing on left

Pedal Arm (

7

) and secure with a Button Head Socket Bolt (

115

) together with

a

Flat Washer (

138

) by using M5 L Allen Wrench (

149

). Do it the same way for

right Connecting Arm (

11

) and right Pedal Arm (

8

).

3.

Remove the Rod End Shafts (

20

) which are pre-assembled on the left and right

Connecting Arms. Assemble the Connecting Arm with the Lower Swing Arm

and secure with Rod End Shafts (

20

)

and

the screw by using

12/14m/m_Wrench (160m/m)(

152

).

ASSEMBLY

STEP 2