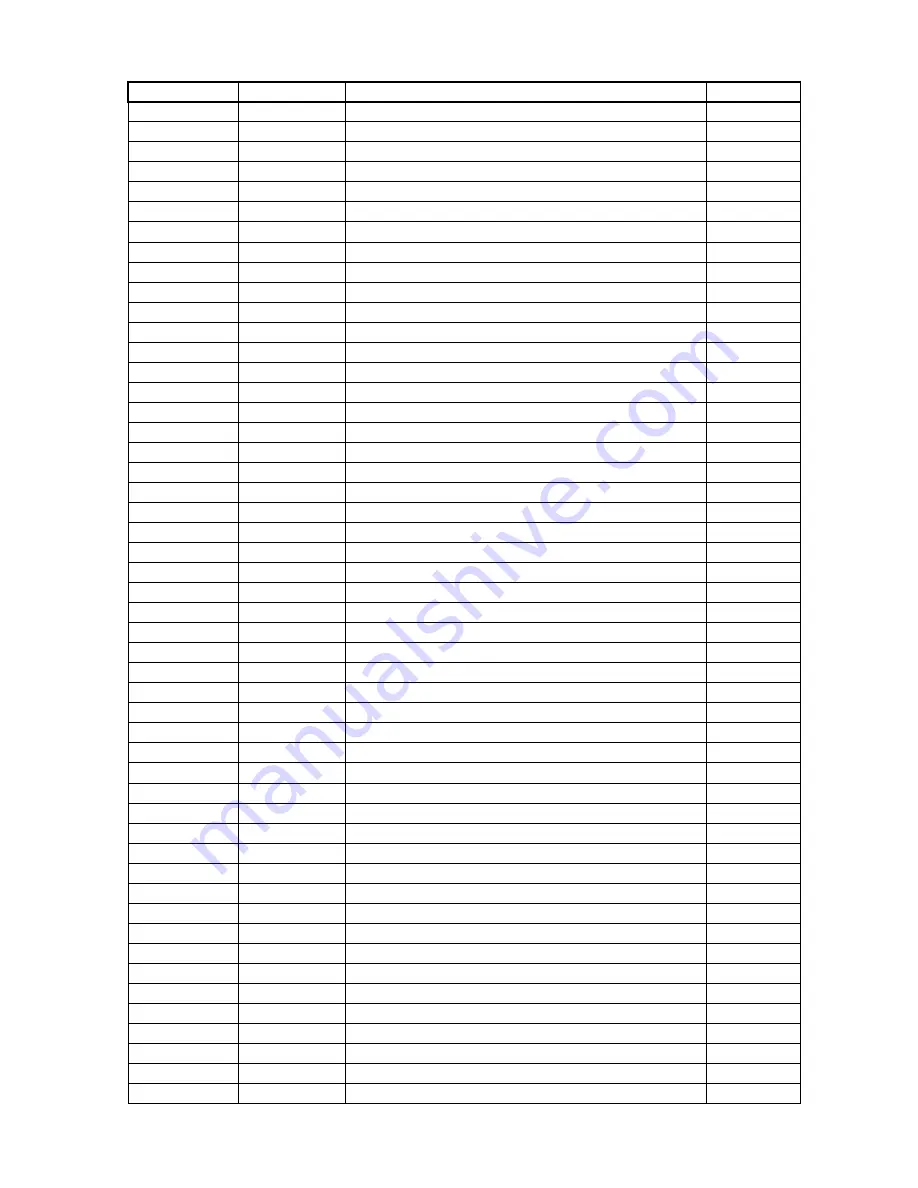

Dyaco Canada Inc. 2013

27

KEY NO.

PART NO.

Description

Q’TY

35~15

17302535-15

LCD Transparent Piece

1

35~16

17302535-16

300m/m_Sound Board W/Cable (White)

1

35~17

17302535-17

250m/m_Amplifier Cable

1

35~18

17302535-18

Speaker Iron Net (L)

1

35~19

17302535-19

Speaker Iron Net (R)

1

35~20

17302535-20

6.5" Water-resist Rubber

1

35~21

17302535-21

LOGO Plate

1

35~22

17302535-22

Key Fast Board (L)

1

35~23

17302535-23

Key Fast Board Foam

2

35~24

17302535-24

Book Rack

1

35~25

17302535-25

Console Resistance Button W/Cable

2

35~26

17302535-26

Key Fast Board (R)

1

35~27

17302535-27

Speaker Grill Anchor

6

36

17302536

400m/m_Connecting Wire, Controller

2

37

17302537

750m/m_Computer Cable

1

38

17302538

1350m/m_Computer Cable

1

39

17302539

AC Electronic Module

1

40

17302540

80m/m_Connecting Wire (White)

2

41

17302541

200m/m_Ground Wire

1

42

17302542

Gear Motor

1

43

17302543

300m/m_Sensor W/Cable

1

44

17302544

850m/m_Handpulse W/Cable Assembly (White)

1

45

17302545

850m/m_Handpulse W/Cable Assembly (Red)

1

46

17302546

Power Cord

1

47

17302547

Resistance Button W/Cable

2

48

17302548

450m/m_Handle Wire (Upper), Resistance

1

49

17302549

450m/m_Handle Wire (Upper), Incline

1

50

17302550

900m/m_Handle Wire (Lower), Resistance/Incline

2

51

17302551

Incline Controller

1

52

17302552

Incline Adaptor

1

53

17302553

400m/m_Audio Cable

1

54

17302554

Incline Motor

1

55

17302555

Chest Strap

1

58

17302558

Transportation Wheel

2

59

17302559

Slide Wheel , Urethane

2

60

17302560

Rubber Foot

6

61

17302561

WFM-1719-12_Bushing

4

62

17302562

J4FM-1719-09_Bushing

12

63

17302563

Drive Pulley

1

64

17302564

Button Head Plug

4

65

17302565

Ø1" × 2.0T_Round Cap

8

66

17302566

Ø32 × 1.8T_Round Cap

2

67

17302567

32 × 2.5T_Round Cap

2

68

17302568

Rubber Foot Pad

2

69

17302569

Ø30 × 60m/m_Oval End Cap

2

70

17302570

Ø40 × Ø80_Oval End Cap

4

71

17302571

3/8" × 35 × 5T_Nylon Washer

2

72

17302572

5/16" × 25 × 3T_Nylon Washer

2

73

17302573

Ø30 × 19m/m_Mast Bushing

2

74

17302574

Ø38 × Ø34 × Ø26 × 4 + 16T_Bushing

2