SOLE S.A. – Solar Collectors – Installation Manual

17

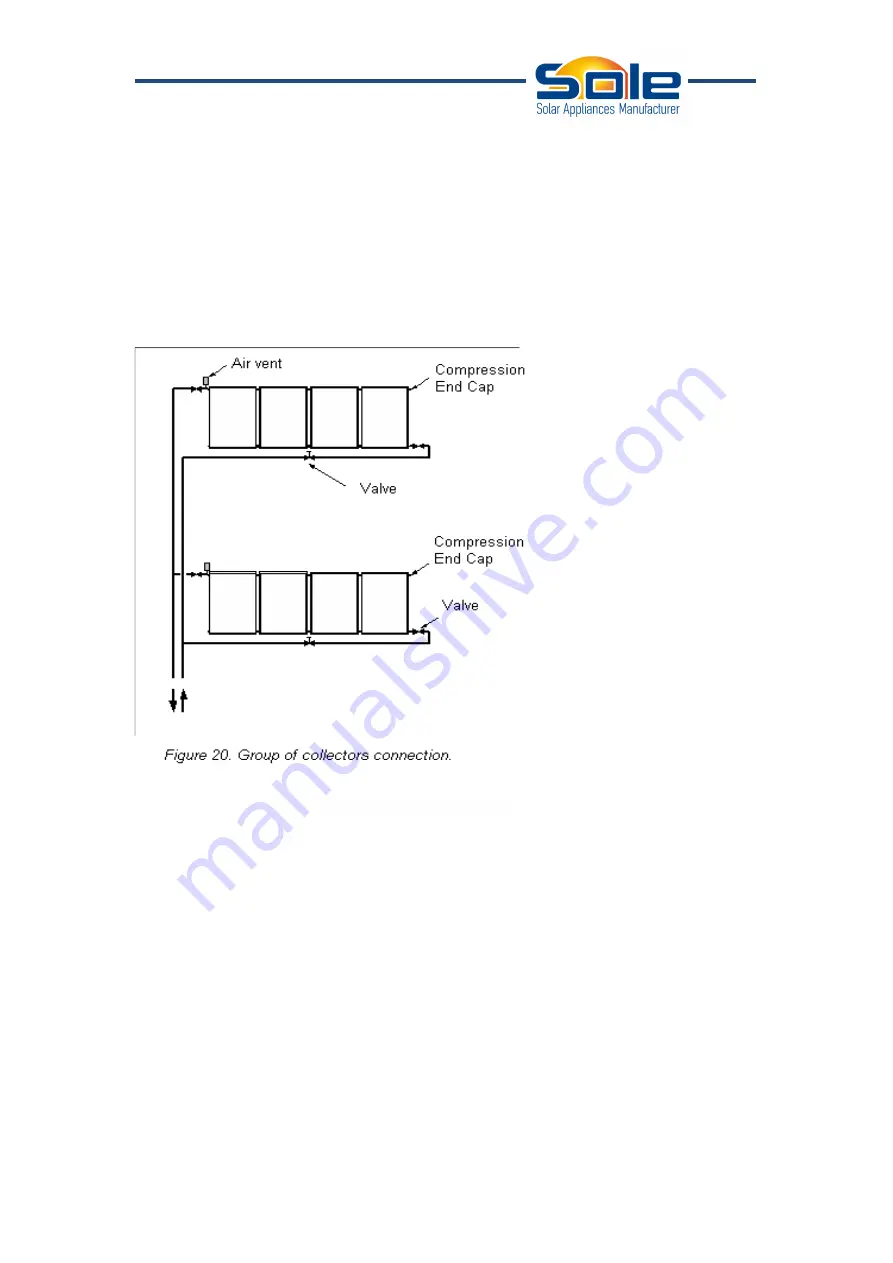

liquid will be done by the top of collector's opposite end of each bank. On the top

connection an end cap must be installed.

The route of the pipeline will be conducted so as to minimize the parts where the flow

of the hot fluid runs (of the collectors towards the tank or to the interchange at the

plant room).

In each group of solar collectors two stop valves should be installed at the entrance

and exit to allow the hydraulic isolation of the rest of the circuit and a safety valve

(figure 20).

The solar collectors reach high temperatures, especially in periods of great sunshine

and low energy consumption, which can cause significant expansion of the materials.

The connection of various groups of solar collectors with each other and / or pipes of

hydraulic circuit must be made so as to ensure that expansion does not cause

excessive pressure (tensions) on the connections or on the collectors, for example

by the use of flexible unions.

In all the high points of the primary circuit of the solar collectors, and particularly the

output of each group of collectors, an air vent must be installed, automatic or manual.

In any case, the air vent must be capable of withstanding temperatures of up to 150 º

C without deterioration. Once the air is drawn out from the circuit, the vents will

remain closed.

A smooth distribution of flow between different groups of solar collectors must be

ensured so that each group has a flow rate close to 100 litres / h for each collector

that is part of this group (i.e. 400 litres / h for every group of 4 solar collectors). This

can be achieved with appropriate design of the route of the pipeline or by installing a