Installation

and

Operation

Manual

(Rev

A)

PVI

50

‐

100KW

Series

Inverters

DOCR

‐

070233

Page

28

of

92

DC

Breaker

Subcombiner

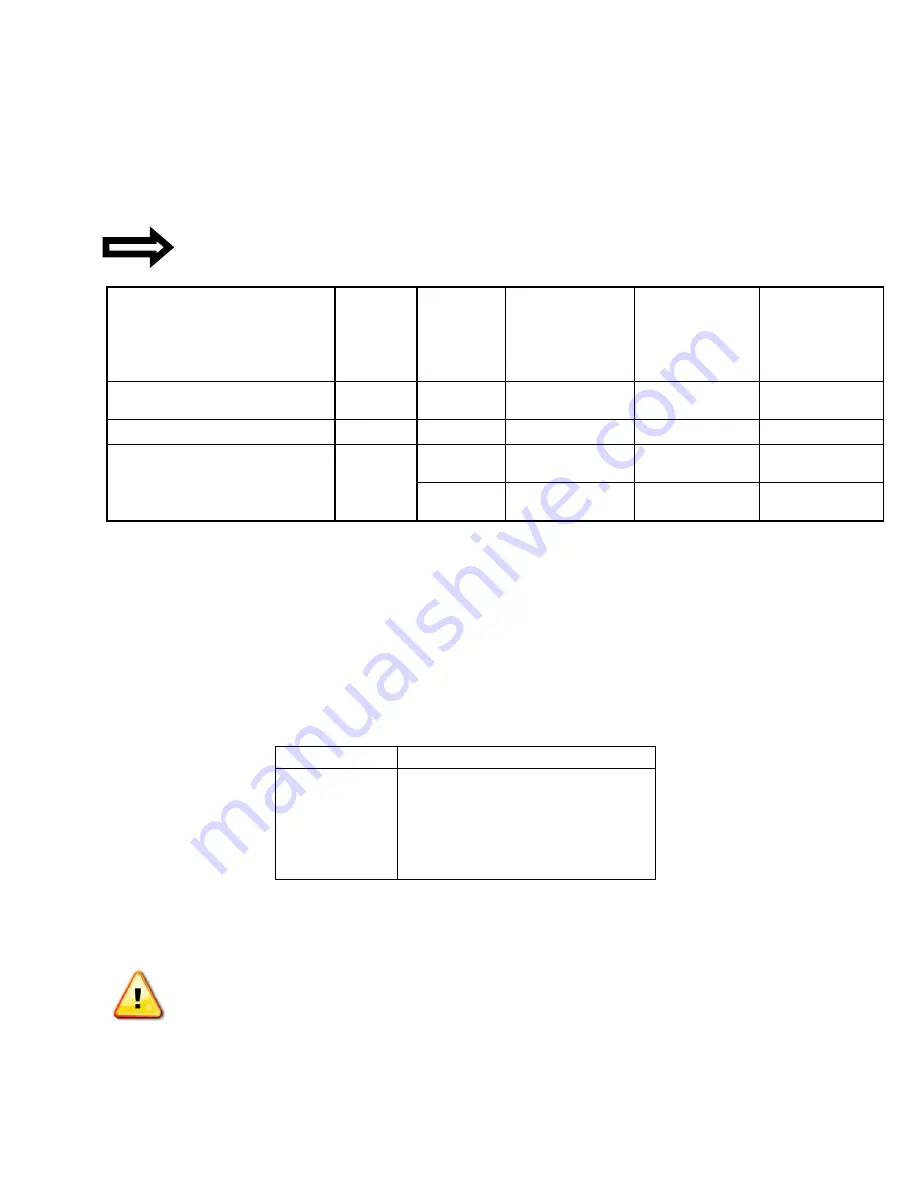

The

table

below

includes

requirements

for

the

DC

conductor

size,

the

number

of

terminals

available

and

proper

terminal

torque

for

the

fused

DC

subcombiner

options

on

the

PVI

50

‐

100KW.

NOTE:

The

torque

is

different

for

the

grounded

and

ungrounded

terminals

on

the

DC

breaker

subcombiner.

BREAKER

CURRENT

RATING

BREAKER

QUANTITY

NO.

OF

TERMINALS

(per

Breaker)

WIRE

GAUGE

TERMINAL

TORQUE

(GROUNDED)

TERMINAL

TORQUE

(UNGROUNDED)

40A,

50A,

60A,

70A,

80A,

90A,

100A

2

‐

8

1

8AWG

‐

1/0AWG

275

in

‐

lbs

45

in

‐

lbs

110A,

125A,

150A,

175A,

200A

2,

3,

4

1

2AWG

‐

300kcmil

275

in

‐

lbs

275

in

‐

lbs

225A,

250A,

300A

2

1

4/0AWG

‐

350kcmil

275

in

‐

lbs

275

in

‐

lbs

2

2/0AWG

‐

250kcmil

275

in

‐

lbs

375

in

‐

lbs

Table

4.9

Fused

DC

Subcombiner

Conductor

Size

and

Torques

4.7

DC

Ground

Fault

Detection

and

Interruption

The

inverter

is

equipped

with

an

automatic

DC

Ground

Fault

Detection

and

Interruption

(GFDI)

circuit.

When

a

single

ground

fault

exceeding

the

ground

fault

fuse

pickup

value

is

present

in

the

PV

array

or

in

the

DC

wiring

to

the

inverter,

the

DC

GDFI

fuse

will

blow

and

a

ground

fault

will

be

signaled

by

means

of

a

yellow

LED

and

a

message

on

the

front

LCD

display.

DC

Ground

Fault

Current

Pickup

PVI

50KW

PVI

60KW

PVI

75KW

PVI

85KW

PVI

100KW

2

Amps

(PN:

Bussmann

KLM

‐

2,

2A

DC,

600

VDC

rated)

REPLACE

ONLY

WITH

SAME

MAKE/MODEL

Table

4.10

–

DC

GFDI

Specifications

WARNING:

In

the

event

of

a

ground

fault,

DO

NOT

TOUCH

any

equipment

(including,

but

not

limited

to:

the

inverter,

the

PV

array

disconnect

switch,

the

PV

array

combiners,

the

PV

panels,

the

PV

racking

system).

Immediately

contact

the

installer

or

another

qualified

person

to

locate

and

repair

the

source

of

the

ground

fault.

Be

aware

that

normally

grounded

conductors

and

equipment

may

be

energized

and

may

pose

a

significant

shock

and

/

or

fire

hazard.