Installation and Operation Manual (Rev E)

SGI Series Inverters

DOCR-060371

5

CAUTION:

Please follow these guidelines:

Be sure to verify load capacity of floor, roof or concrete pad mounting area.

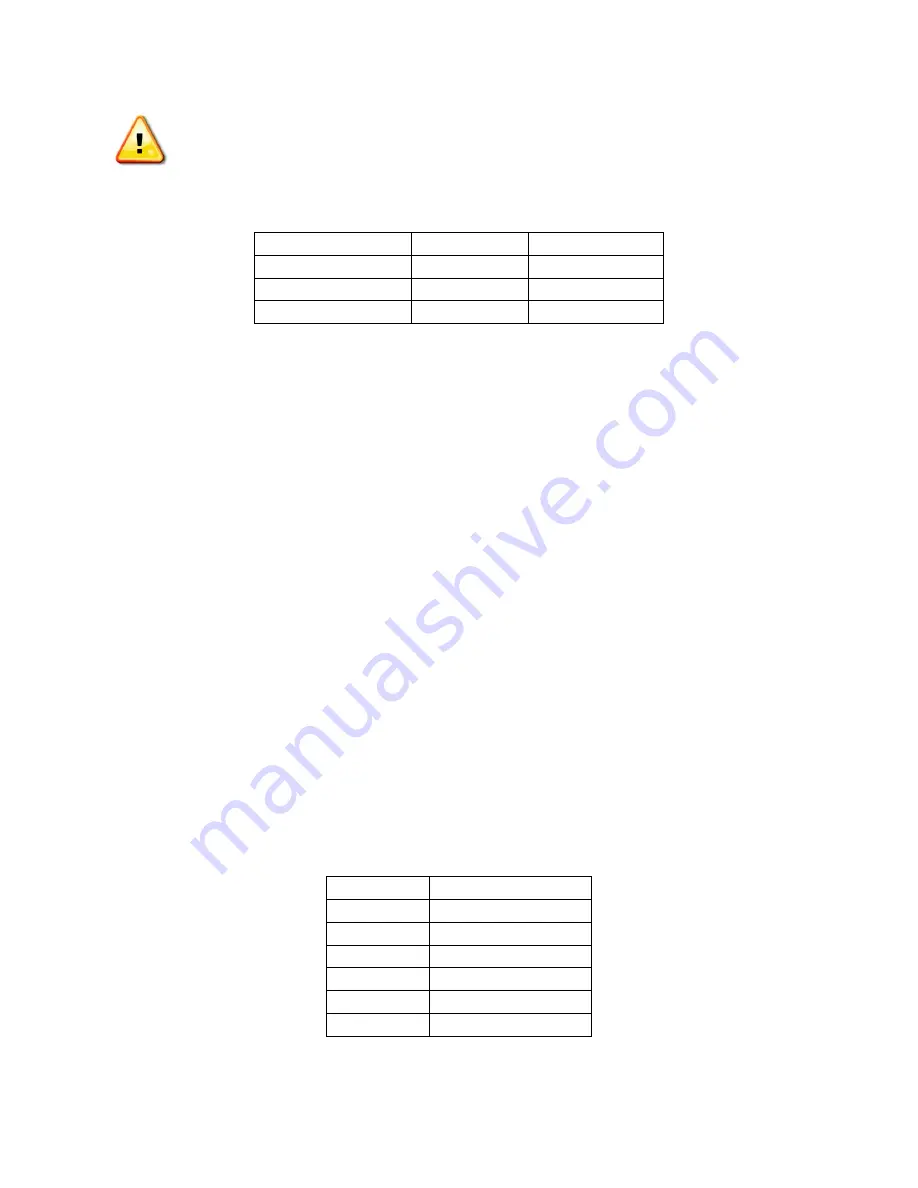

Table 2.1 – Weight and Required Fork Lift Capacity

The ambient temperature must be between –40

o

C and +50

o

C for full power, continuous

operation. The inverter will automatically reduce power or may shut down to protect itself

if ambient air temperature at the intake rises above 50

o

C.

The National Electrical Code (NEC) requires that the inverter be connected to a dedicated

circuit and no other outlets or device may be connected to this circuit. See NEC Article 690.

The NEC also imposes limitations on the size of the inverter and the manner in which it is

connected to the utility grid. See NEC Article 690 for guidance within the US.

A minimum distance of 18 inches must be clear

behind

the inverter for cooling air exhaust

and service access. A clearance distance of 36 inches behind the inverter is highly

recommended to aid in cleaning the exhaust screens.

A minimum distance of 12 inches must be clear

above

the inverter for ventilation.

A minimum distance of 6 inches must be clear to the

sides

of the inverter.

If you are installing the inverter in a utility vault or electrical closet, the air circulation must

be sufficient for heat dissipation. Provide external ventilation to maintain an ambient

condition of less than 50

o

C. The ambient temperature should be kept as low as possible at

all times for optimal inverter operation and life.

Model

Max. heat loss

SGI 500

55000 Btu/hr

SGI 500PE

55000 Btu/hr

SGI 300

32000 Btu/hr

SGI 266

28000 Btu/hr

SGI 250

26000 Btu/hr

SGI 225

24000 Btu/hr

Table 2.2 – Indoor Cooling Requirements

Inverter Model

Weight

Fork Lift

SGI 500, 500PE

6980 lbs.

8000 lbs

SGI 300, 266, 250

5650 lbs.

6000 lbs

SGI 225

5170 lbs

6000 lbs