Installation and Operation Manual (Rev E)

SGI Series Inverters

DOCR-060371

12

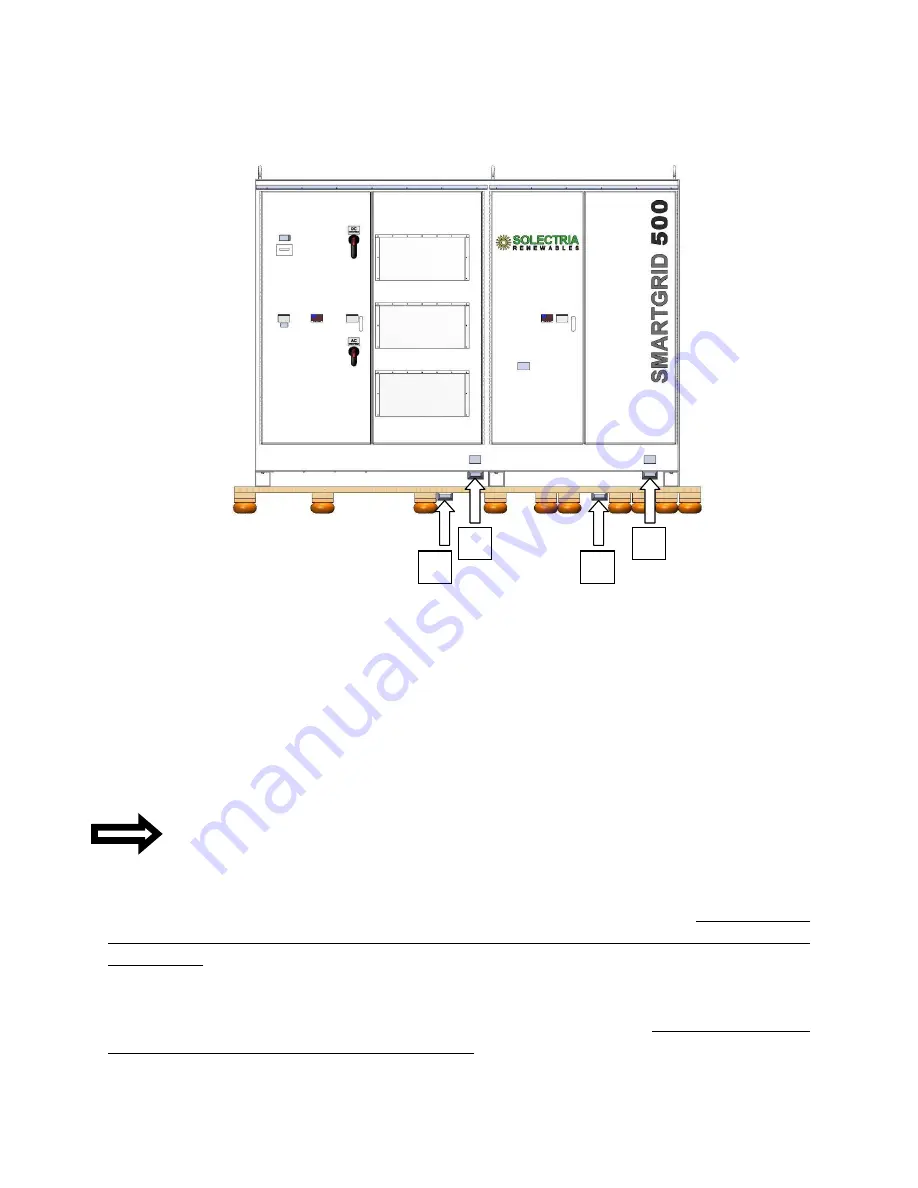

Figure 3.1 – Forklift Lifting Positions

Use positions A when lifting or moving the inverter while attached to the pallet

Use positions B when lifting or moving the inverter removed from the pallet

Note that the lifting diagrams show the inverter being lifted while mounted on the shipping

pallet. If the inverter is lifted without the shipping pallet, a properly rated safety strap must be

placed over the top of the inverter firmly holding it down on the lifting devices forks. It is

recommended to use two lifting straps, one holding the inverter to the left fork and another to

the right fork.

NOTE:

Failure to follow these lifting guidelines may cause structural damage to the

inverter and void the warranty.

Alternatively, the inverter can be lifted using the lifting eyes on the top. If using this lifting

method, lift with vertical chains and hooks connected to a proper lifting device.

Do not lift with

an “A” chain between the two eyes left-to-right as this will result in permanent damage to

the inverter.

At a minimum, use 3 “A” chain sets going front-to-rear with each side of the “A”

having a chain length of 4 feet minimum. Each “A” chain must be tensioned equally. The

recommended method is a 3 beam hoist with 6 equal-length tensioned chains hanging down,

one over each eye bolt. An A-frame can then be used above the 3 beams.

Never lift only by the

outer 4 eyebolts as this will damage the inverter.

B

B

A

A