7

1.800.627.4499

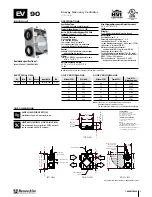

GR90, EV90, EV90P

ERV

9

1.2.1 Purpose of an ERV System .........................................................................................................9

1.2.2 When Should You Use Your ERV ..................................................................................................9

1.2.3 Using an ERV with Air-Conditioning ............................................................................................9

1.2.4 Controlling Excess Humidity During Cold Weather .......................................................................9

2.0 UNIT PLACEMENT

9

2.1 BEFORE YOU BEGIN .............................................................................................9

2.2 LOCATION OF THE UNIT .....................................................................................10

2.3 DUCT SIZES AND INSULATION ............................................................................10

2.3.1 Duct Sizes ............................................................................................................................... 10

2.4 DUCTWORK APPLICATIONS ................................................................................11

13

3.2 INSTALLING OUTSIDE AIR AND EXHAUST AIR DUCTS ..........................................14

3.3 INSIDE DUCTWORK SYSTEM (FOR WALL MOUNTED UNITS ONLY) ........................14

3.4 INSTALLING RETURN AIR DUCTS ........................................................................14

3.5 CONTROLS ........................................................................................................15

3.5.1 Installing Controls .................................................................................................................... 15

16

16

4.2.1 Airflow .................................................................................................................................... 16

4.2.2 Use Static Taps to Measure Airflow Rates ................................................................................ 16

4.2.3 Use Damper to Balance Airflow to Desired Rates ...................................................................... 16

4.3 MEASURING AIRFLOW .......................................................................................17

4.4 MEASURING CROSS CORE STATIC PRESSURE ....................................................17

18

5.1 TO CLEAN THE ENERGY EXCHANGE ELEMENT ....................................................18

5.2 INSPECT AND CHANGE THE FILTERS REGULARLY ................................................18

5.3 MOTOR MAINTENANCE ......................................................................................19

5.4 GENERAL CLEANING AND INSPECTION ...............................................................19

5.5 SERVICE PARTS .................................................................................................19

19

TABLE OF CONTENTS