12’ Garden Master (3.5mm) Page 9

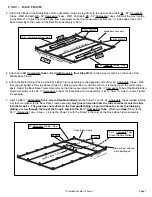

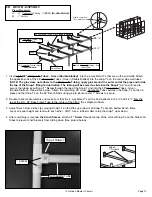

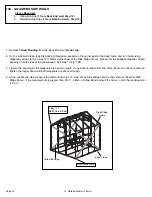

1. Slide the non-slotted end of each

90” Composite Tube - Yellow (Single-Slotted)

into a

Metal Corner Post

(Insert tube

into the arm with the red mark) and tighten the eyebolt. Attach a

35 ¾” Composite Tube - White

between the Metal

Corner Posts attached to the 90” Composite Tubes - Yellow (Single-Slotted). Adjust the 90” Composite Tubes with the

metal corner posts attached so the distance between the Metal Corner Posts is 36 ½” from “in” side to center. Tighten

the eyebolts.

2. Attach a Snap-T to each

90” Composite Tube - Yellow (Single-Slotted)

, about 13” below the Metal Corner Post. Insert

and glue a

35 ¾” PVC pipe - White

between these Snap-T’s.

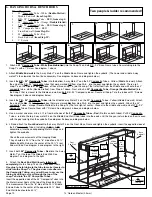

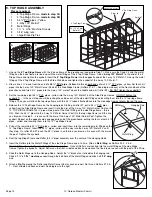

3. Attach two

Snap-T’s

on to both 35 ¾” pipes. Attach and glue a

12 ½” PVC pipe - White

between these Snap-T’s. Slide

each 12 ½” pipe (With snap-t’s attached) over so it is 10 ½” from the “in” side of the 90” tube to the center of the 12 ½” pipe

(leaving about 13 ½” between the 12 ½” pipes).

NOTE:

This spacing applies when installing a 12” Exhaust Fan. If installing a 16” fan or larger, replace the 12 ½” pipes with

the larger pipes included with the fan (refer to Fan installation instructions).

If a Fan was not purchased, slide over both

12 1/2” pipes (with snap-T’s attached) to the edge of the Metal Corner Posts.

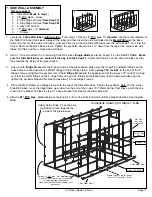

4. Attach two

Snap-T’s

on each 90” Composite Tube - Yellow (Single-Slotted). The center of the top Snap-T is at 48 ¼” from

the bottom of the 90” composite tube - Yellow (Single-Slotted) and the center of the 2nd Snap-T is at 22 ¾” from the

bottom of the 90” Composite Tube - Yellow (Single-Slotted).

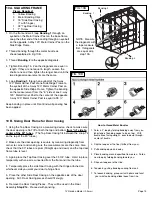

5. Attach a

Snap-T

on each 90” Composite Tube - Yellow (Single-Slotted) between (Approximately - it can be adjusted later)

the top and bottom Snap-T’s attached in the previous step (Step 5C-4). Insert and glue a

35 ¾” PVC pipe - White

into

these Snap-T’s.

6. Attach an additional Snap-T on each 90” Composite Tube - Yellow (Single-Slotted) below the Snap-T you just put on in

step 5C-5.

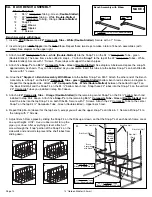

5C. Back End wall Frame

Pieces Required:

2

90” Composite Tubes - YELLOW

(Single-Slotted)

2 Metal Corner Posts

2

35 ¾” PVC Pipes. - WHITE

1

35 ¾” Composite Tubing - WHITE

14

Snap-T’s

2 12 ½” PVC pipes - WHITE

35 ¾” Composite Tube - White

90” Composite Tube -Yellow

(Single-Slotted)

12 ½” PVC pipe - White

Snap-T

Metal Corner Post

(Arm marked with red)

22

¾”

48 ¼”

35 ¾”

PVC pipe

White

35 ¾”

PVC

pipe

White

Slotted end

Snap-T

Snap-T

36 ½”