Manuel HM acoustic housing

5

concept

SonaSafe type

material

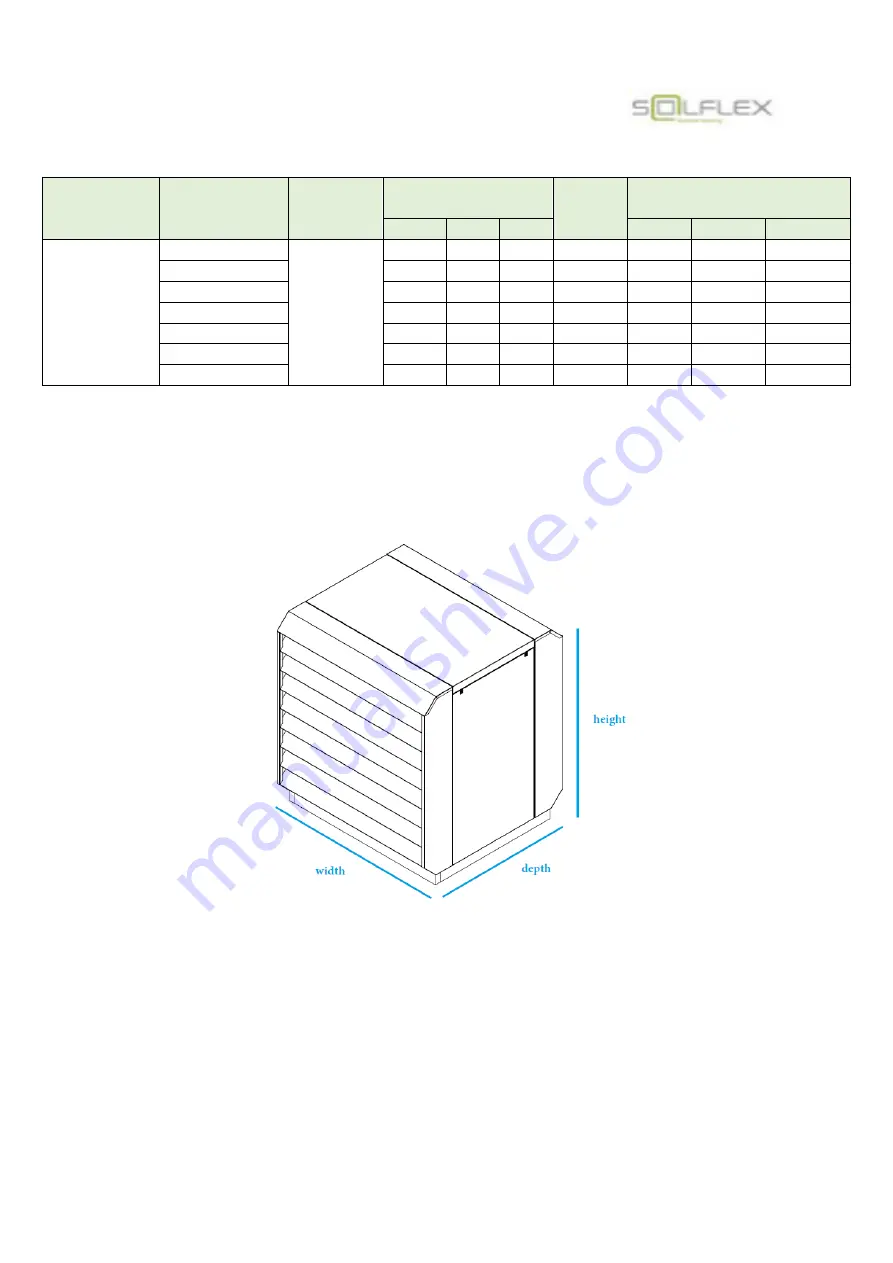

dimensions [mm]

weight

[kg]

Max. device dimension

[mm]

h

w

d

h

d

d

Suction in the

rear, blowout

in the front

HM100NP

galvanized

steel sheet

1060

1200

1250

123

990

1060

650

HM200NP

1420

1200

1250

159

1350

1060

650

HM200NP-l

1420

1400

1400

185

1350

1260

800

HM200NP-XL

1420

1600

1500

209

1350

1460

900

HMY200NP

1740

1200

1250

195

1670

1060

650

HMY200NP-L

1710

1400

1400

227

1670

1060

650

HMY200NP-XL

1740

1600

1500

255

1670

1460

900