8

500

1

2

14

0

50

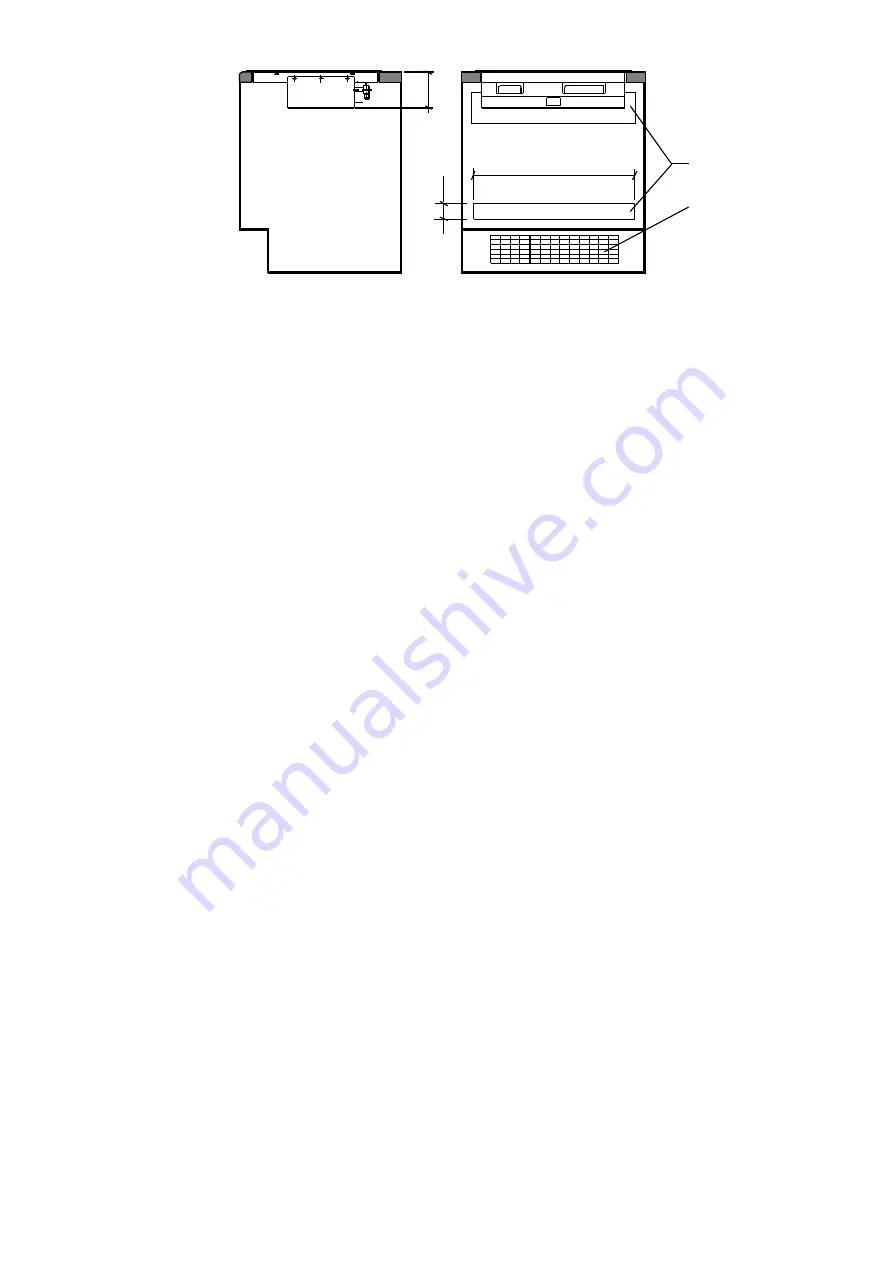

side view

front view

Fig. 5

Chart of 8ssembly

1-VENTILATION AIR INLET, 2- VENTILATION AIR INLET WITH MESH

REMARKS:

- Due to the height of the hob, it is impossible to install it over an oven in standard kitchen

cabinets.

- If the kitchen cabinet has a back wall, it is absolutely necessary to cut out ventilation openings in

it, as shown

on the drawing

.

fig. 5,

- Because of the need to assure circulation of air, an air inlet grate should be installed in the skirting

of the cabinet

fig. 4.

2.3

Gas supply system

1.

GPC-2

have a vertical connector pipe ending with an R1/2” outside thread (ISO 7-R1/2) for

connecting the hob to the gas supply system. It is recommended that the hob be connected to the

gas supply system with a flexible connecting hose with a

safety certificate

.

2.

If the hob is supplied by means of a flexible connecting hose, it is necessary to use an R ½ /G ½

screw-in/screw-on elbow. A cut-off valve must be installed in the system to stop the supply of

gas to the hob, as well as a gas filter preventing the nozzles from clogging due to polluted gas.

3.

If the hob is to be supplied with liquid gas from a gas cylinder, a ø10/R1/2” connector pipe is to

be screwed into the gas supply connector pipe, after removing the ½” nipple. A

liquid gas

regulating valve

needs to be installed on the cylinder valve. The regulating valve is connected

with the hob with a flexible hose for liquid gas (max. length 3 m) with clamps on both ends.

The regulating valve and the flexible hose must have safety certificates.

-

The above activities, for the sake of the user’s safety, should be performed by an authorized gas

installation technician!

2.4. Electric system

The control system of the hob is supplied with 12 V direct current through a power supply. In

order to assure correct and safe operation of

GPC-2

hobs, it is necessary to provide an electric

socket (230 V/50 Hz) close to the location of the stove in order to connect the hob’s power supply.

The electric socket should have a grounding bolt and cannot be located directly over the hob, at the

distance of less than

10 cm away from the side

of the stove and at least

10 cm above

the top plane

of the hob plate, away from the area affected by

hot fumes

exhausted in the back of the hob.

Moreover, it is necessary to provide properly ventilated place for the power supply. In other

places, a special cable to connect the hob with a 12 V DC system will be provided on request.

3. USE OF THE HOB

3.1

The startup of the hob should be performed by

an authorized

technician in the

buyer’s

home.