SOLID AIR ®

CLIMATE SOLUTIONS

•

T +31 598 36 12 21

•

www.solid-air.com

•

mail@solid-air.com

31

- 58

Product overview

Technical data

Ordering key

Installations

Accessories

Replacements

Maintenance and operation

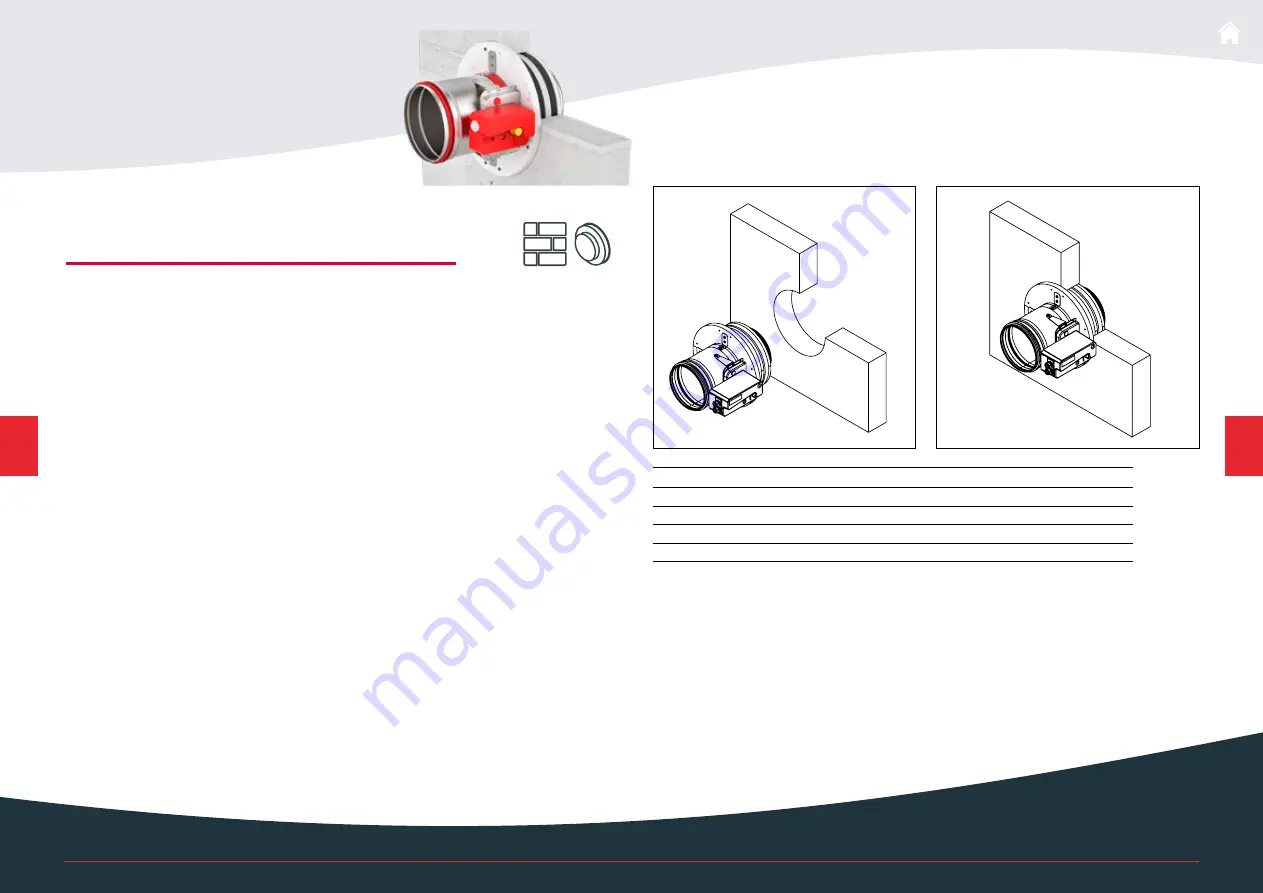

The wall is composed of concrete blocks (minimum density of 550 kg/m³) or reinforced

concrete (minimum density of 2200 kg/m³) and with a minimum thickness of 100 mm.

Wall opening dimensions

Damper Ø d [mm]

Applique frame Ø D [mm]

Wall opening [mm]

100

Ø d + 105 mm

Ø d + 115 mm

125-180

Ø d + 95 mm

Ø d + 105 mm

200-315

Ø d + 80 mm

Ø d + 90 mm

INSTALLATION

1. Create a wall opening according to the dimensions in the table below.

Damper blade must be closed during installation!

2. Insert fire damper into wall and fasten with screws (8 pcs, 4.8 x 60 mm).

Test the operation of the damper blade!

RIGID WALL INSTALLATION

APPLIQUE INSTALLATION FRAME

1

2

>

>