The system parameters can be checked and adjusted via the controller. But they should not be changed

casually, especially by house owners.

9.4 Parameter checking and Setting

This operation is reserved to facilitate future service and maintenance. All

parameters should not be changed casually, especially by house owners!

How to check and adjust parameters:

! Warning !

Heat Pump For Heating And Cooling Series

23

User parameter checking and settings (avail in both ON and OFF state)

In the main interface, press

“

function

”

key

for 3 seconds

to

enter

user

parameter

and

settings

interface

;

press

“+”

or

“-”

to

check

each

parameter

.

Press

“

function

”

to

enter

current

user

parameter

settings

interface

,

press

“ +”

or

“ -”

to

modify

the

value

,

again

press

“

function

”

key

to

return

to

query

status

.

Under parameter

or setting interface, if no operation to the controller within 30 seconds, the

controller will return to main interface automatically. The controller also can back to main interface via

pressing ON/OFF key.

Factory parameter

and settings (avail in both ON and OFF state)

In the main interface, together press

“

ON/OFF

”

and

“+”

keys

for 3 seconds

to

enter

factory

parameter

password

interface

.

In

this

interface

,

press

“

time

”

to

switch

code

digits

,

press

“ +”

or

“ -“

to

modify

the

value

of

each

digit

,

and

press

“

function

”

key

to

input

your

password

,

if

the

password

is

correct

,

the

controller

will

enter

factory

parameter

check

interface

.

(

factory

check

password

:

0814

)

In the factory checking interface, press

“

function

”

to

enter

current

factory

parameter

settings

,

press

“+”

or

“-“

to

modify

the

value

of

the

parameter

,

and

press

“

function

”

to

return

to

query

status

.

Under factory parameter query or

setting

interface

,

if

no

operation

to

the

controller

within 30

seconds

,

the

controller

will

return

to

main

interface

automatically

.

The

controller

also

can

return

to

main

interface

via

pressing

ON

/

OFF

key

.

checking

checking

checking

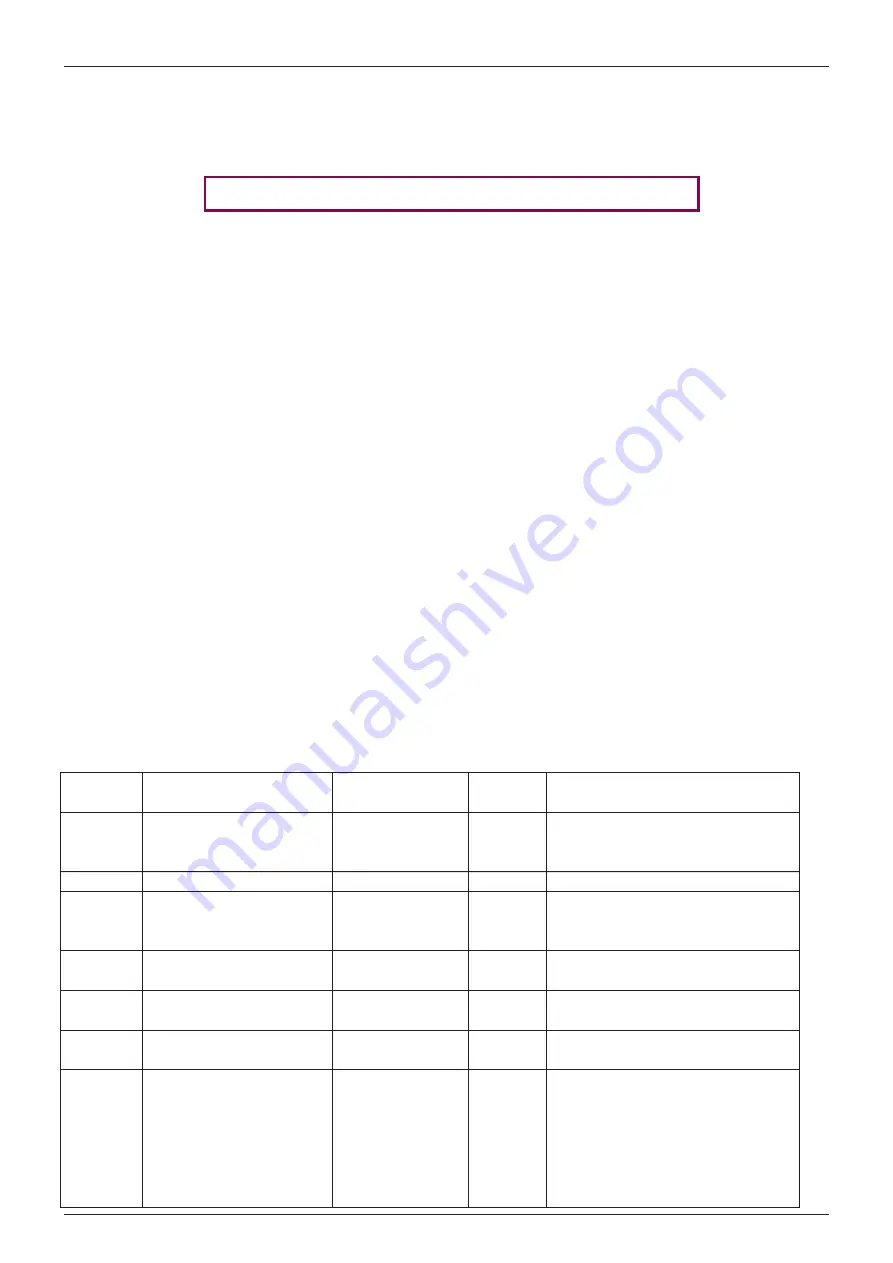

9.5 Paramete r number and descriptio n are liste d in th e fo llowing ta ble.

9.5.1 User Parameter (Available

for

end

users)

Para m eter

code

Pa ram e ter s de scr ip tion

Se tting ra nge

D e fau lt

v alue

Notes

L0

W ater temp

hyste re sis (D HW )

2~18

℃

5

℃

Machin e sto ps w h en w ater temp >=se t

te mp + h ys teresis, ma chin e re sta rts

wh en w ate r temp <= set temp - hyste re sis

L1

Se ttin g wa ter temp (D HW )

2 0

℃

~Pa ra meter F1

55

℃

De fau lt D HW w ater te mp

L2

W ater temp erature

h ys teresis(H ea tin g/C oo ling )

2

℃~

18

℃

3

℃

Mach ine stop s w h en w ate r te mp>=set

temp + hystere sis, mach ine restarts

w he n wa ter te mp<=set te mp - h ys teresis

L3

Se ttin g wa ter temp eratu re o f

H ea tin g mo de

2 0

℃~

Parame ter F1

50

℃

D efau lt w a te r temp fo r He atin g

L4

Se ttin g wa ter temp eratu re o f

C oo ling mo de

7

℃~

30

℃

12

℃

D e fa ult w ater te mp for C oo ling

L5

Th e amb ien t te mpe ra tu re to

start au xiliary ele ctrical he ater

-30

℃~

35

℃

0

℃

W he n amb ien t temp < set va lu e, tu rn o n

the a uxilia ry e lectrica l h ea te r

L6

C omp re sso r cu rren t protection

valu e

0

~

4 0A

1 00 :2 3A

2 00 :1 3A

3 00 :1 0A

3 80 :1 3A

4 50 :1 5A

5 50 :1 3A

6 30 :1 5A

If set to 0, me an s ig no re

th is valu e