Levelogger User Guide - Software Version 3.4.0 or Higher

Page 44

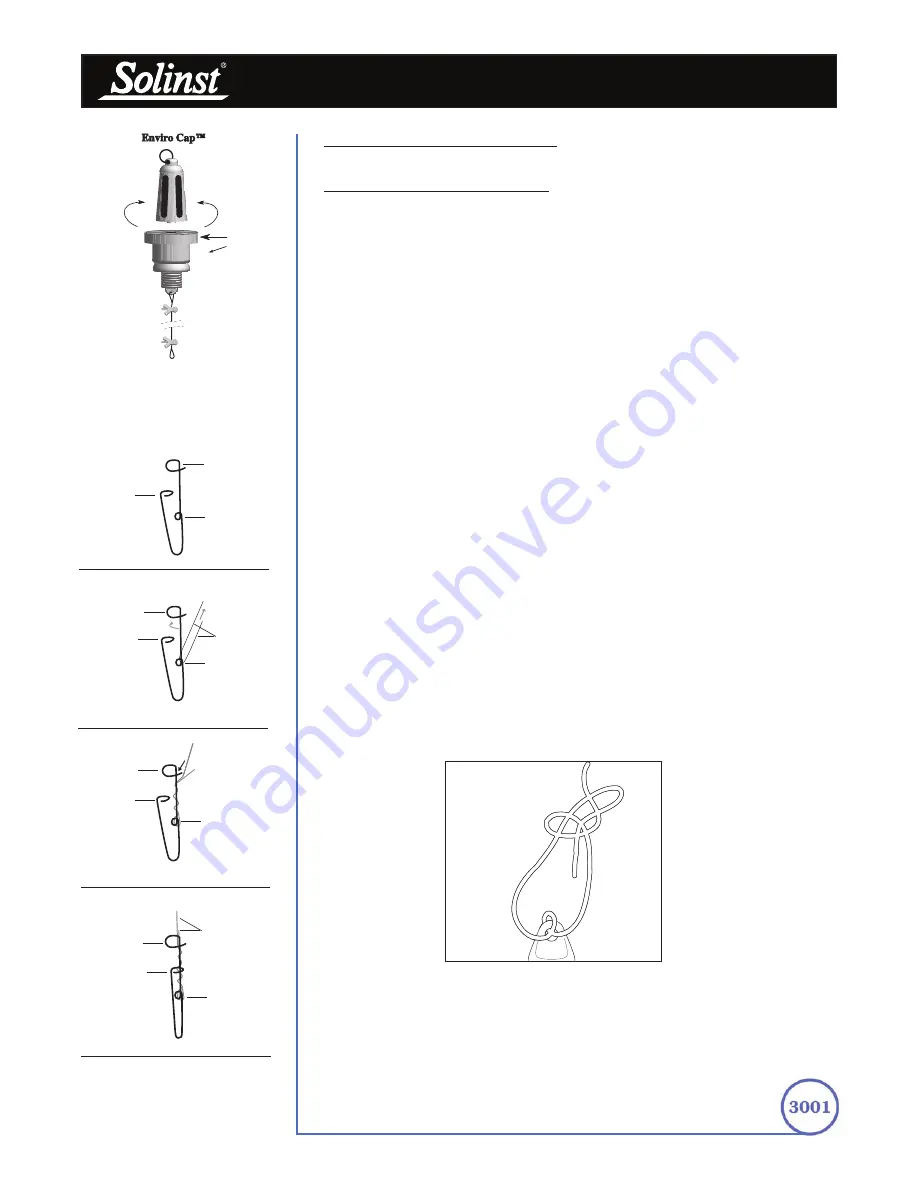

11.1.1 Free Suspended Installations

Suspension Wire/Rope Installation

When installing using a suspension wire or rope, the Levelogger is pre-

programmed and started using the software. It is then deployed using a

suspension wire or rope connected to the installation cap of the Levelogger

to the underside of a well cap. The data is retrieved manually, by withdrawing

the Levelogger, removing the installation cap and attaching an Optical Reader

directly to the datalogger. Data is downloaded to a desktop or laptop PC or by

using a Leveloader Gold.

Solinst supplies stainless steel suspension wire assemblies including SS stranded

wire and hooks available in a variety of lengths from 50 ft (15 m) to +500 ft

(+150 m), and Kevlar rope assemblies. Solinst also supplies a specially designed,

tamper-proof, vented, locking well cap known as the Enviro-Cap™ from which

the Levelogger can be suspended.

This type of installation is applicable to both submerged and barometric record

applications. Follow these steps to install the Levelogger using stranded cabling

and hooks:

1. Loop the cable through the coil 2 of the hook assembly, then wind the looped

strands several times around the hook shaft and pass through coil 1.

2. Pass coil 3 through the Enviro-Cap™ eyelet or Levelogger/Barologger eyelet

and snap coil 3 to the hook shaft.

3. If the Enviro-Cap™ is not used then some secure tie-off point should be used

or installed.

4. If installing a Barologger, ensure the suspension level is above the highest

expected water level.

5. When retrieving data and/or reprogramming the Levelogger, extract it from

the monitoring location, unthread the installation cap, interrogate and re-

suspend the unit rechecking the security of the wireline clamps each time.

HOLD

HERE

Loosen

(counter-

clockwise)

Tighten

(clockwise)

Figure 11-2

Locking, tamper-proof

Enviro-Cap Step 1

Coil 1

Coil 1

Coil 1

Coil 1

Coil 3

Coil 2

Coil 2

Coil 3

Coil 2

Coil 3

Coil 2

Coil 3

Wireline

Wireline

Wireline

Diagram 1

Diagram 2

Diagram 3

Diagram 4

Figure 11-3 Wireline Hook

Installation

Bowline

Knot

Figure 11-4 Bowline Knot Used to Connect Kevlar Rope to the Levelogger