ENGLISH

7

2 Preparing the device for use

2.1 Assembly

The backpack sprayer is dismantled before it is

dispatched. It must be fully reassembled again

before it is used.

Installation of the pump lever:

Fig. 3 – Fig. 7

The pump lever can be attached to either side of

the device. The figures show mounting on the left

(on the right, mounting is performed accordingly).

Fig. 3:

When fitting the pump lever, the retaining tube (b)

of the pump lever should be facing upwards and

back (facing towards the tank inscription).

Fig. 4 , Fig. 5:

1. Push washer onto the shaft

2. Push pump lever onto the shaft

3. Screw the pump lever to the shaft with screw

and washer, secure with nut.

Fig. 6:

The pump lever length can be adjusted in three

lengths. For this, depress the pin (i), move the

pump handle (c) and latch the pin (i) in one of the

three bores (j).

Fig. 7:

To put down the device, the pump lever can be

turned up with the pump handle (c) in the holder

pipe (b).

For work, turn the pump lever down again with the

pump handle (c) in the holder pipe (b).

Outside of work, the spraying tube (e) is attached

to the carry handle (d).

Installation of the spray tube:

Fasten the threaded collar (Fig. 2, pos. h) on

straight and firmly screw the spray tube (e) with

O-ring (16x3 mm) hand-tight onto the shut-off

valve (g). Do not use any tools!

At the factory, a yellow flat jet nozzle 02-F80 is

assembled as the standard spray nozzle.

2.2 Checking for operationally safe condition

Before any use, the backpack sprayer must be

subjected to a visual inspection. There must be no

visible cracks at the tank (a), the spray tube (e) and

the nozzle attachment (f).

The following inspections must be performed at

first commissioning and at recommissioning after

extended standstill. During use of the pressure

sprayer, proper function generally must be verified

in operation.

To verify tightness even with the tank pressurised,

build up pressure across the pump and inspect the

entire device. No liquid must escape before

actuating the shut-off valve, even while the tank is

pressurised.

Check the function of the shut-off valve during

application. When releasing the shut-off valve,

spraying must stop and no liquid must escape

anymore.

In case of irregularities, recognisable damage,

leaks or limited function, do not start work but have

it inspected by a specialist workshop.

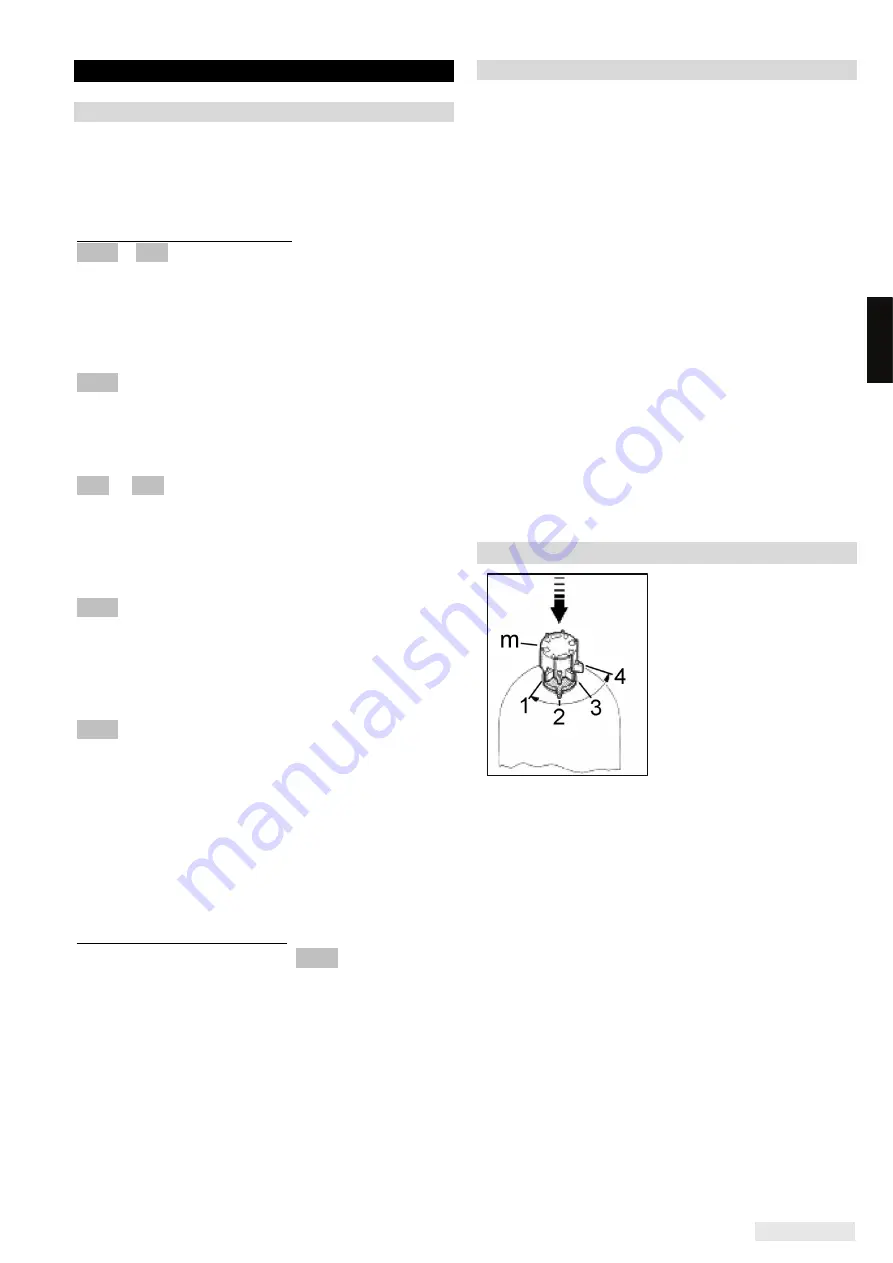

2.3 Pressure

adjustment

The pressure is adjusted

prior to filling the tank by

turning the adjuster

cap (m) on top of the

pressure tank. Press down

the adjuster cap and locate

the selected pressure

marker tooth over the tooth

on the pressure tank.