4

PREPARATION AND SAFETY

• Always wear safety glasses or eye shields when using your

spreader.

• Dress properly. Wear only closed toed shoes with good traction.

Do not operate spreader when barefoot or wearing open

sandals.

• Wear long-sleeved clothes that are snug fitting. Avoid wearing

loose clothing.

• Wear either tightly cuffed or cuffless pants.

• Wear non-slip gloves during operation. Wear a respirator if

appropriate for the type of material being spread.

• Long hair should be tied back and kept away from the

spreader.

• Make directional adjustments before using the spreader.

• Use only in daylight or good artificial light.

• Read all instructions of the chemical manufacturer.

CAUTION

• Keep your eyes and mind on the job at hand. Do not become

distracted.

• Always be sure of your footing. Use extra caution in wet or

slippery areas. WALK - DON’T RUN.

WARNING: Chemicals or materials which can be harmful to

individuals or the environment should be avoided. Follow all

warnings of the chemical manufacturer.

MAINTENANCE AND STORAGE

• Check all bolts, nuts, and screws at frequent intervals for

proper tightness to be sure the spreader is in safe working

condition.

• Keep all safety devices in place and working.

CUSTOMER RESPONSIBILITIES

• Read and observe the Safety Rules.

• Follow a regular schedule in maintaining, caring and using

your spreader.

• Follow the instructions under the Maintenance and Storage

sections of this manual.

ASSEMBLY

Your SOLO 421 spreader needs to have the carry strap and the

crankhandle attached before operation.

Remove the hopper lid. The crank handle and carry strap are

located inside.

Mounting the Crank Handle

• Place the spreader on it’s left side (as viewed from the

operators position). Figure A.

• Find the threaded crankshaft and affix the crank handle in a

clockwise motion, tighten the jamnut against the crank handle.

Carry Strap

• Stand the spreader upright at about waist level on a table,

bench or stand.

• Adjust the strap to ist longest reach.

• Attach the strap hook to the top right eye on the hopper (as

viewed from operator’s position).

• With the back of the spreader facing your chest, slip the strap

over your right shoulder and across your back.

• Set strap hook under spreader housing. See Figure B.

• With the spreader fitted, crank the handle and determine if

the spreader is set at a comfortable height. Remove the

spreader, adjust the strap and try again until you are

comfortable with fit and function.

Lubrication Point

• With the spreader on it’s right side (crankhandle side up),

observe the small oil hole in the gearcase.

• Add a few drops of light oil every four hours of operation

Figure C.

Adjusting the Spreader

Your spreader is adjustable for both volume and direction. Four

factors determine the volume and derection. They are:

Flow Limiter Stop -

This brass stop nut allows you to limit the

hopper opening for consistent delivery of material to the impeller.

Flow Rate Lever -

Look down into the hopper to observe how

the drop chute opening varies as you adjust the flow rate lever.

Directional Lever

- This control adjusts the point where the

material is to be deposited on the impeller and consequently, the

width of spread. The lever can be set for center, left or right

spreading. Figure D.

Deflector Shield

- Increase or decreases the width of spread.

Figure E.

Cranking Speed -

Cranking faster or slower affects volume and

coverage.

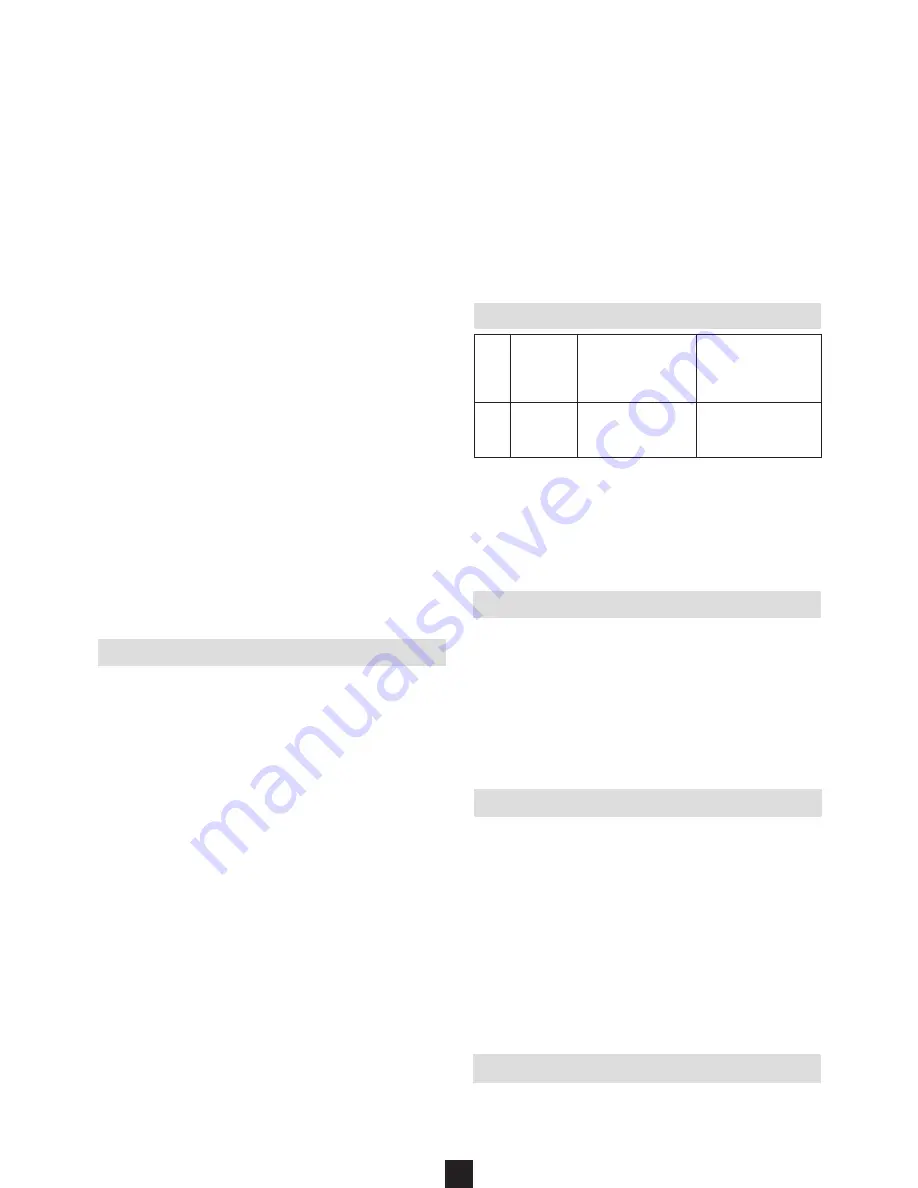

SPREAD RATE TABLE

Pelletized fertilizer is usually thrown about 10-12 feet (300-400cm)

in front of the operator and about 5-7 feet on each side at 55-60

rpm. Grass seed usually carries 5-6 feet (180-200 cm) forward and

4-5 feet (150-170 cm) to the side. A walking speed of 2.5 to 3.0

feet per second (80-90 cm/sec) is suggested.

Please test the product you are spreading to achieve the

manufacturer’s recommended coverage.

FILLING THE HOPPER

• Move flow rate lever to zero position.

• Set spreader on a flat surface.

• Remove hopper lid.

• Fill hopper. For the initial use it is wise to partly fill the hopper

and practice spreading and making adjustments.

• Replace hopper lid - the lid prevents spillage and heilps keep

dust and otrher material away from the operator. When

spreading chemicals be sure to wear protective clothing,

respirator and eye protection.

• Do not load hopper while carrying spreader.

OPERATING INSTRUCTIONS

• Set spreader on a surface to safely and conveniently fit the

carry strap as outlined in assembly section.

• Set deflector to desired position.

• Adjust spreading direction lever to the desired position.

Directional changes can also be made simply by walking in the

desired direction.

• While turning the crankhandle with your right hand, move the

flow rate lever with the left hand to adjust flow rate. Flow

limiter stop will control flow rate. Caution: Keep hands away

from rotating impeller.

• After use, turn the flow rate lever to the closed (zero) position.

Crank the handle several times to make sure no material

residue is attached to impeller. Clean the whole unit

thoroughly using soap and water.

OTHER OPERATINS SUGGESTIONS

• Walking speed: 2.5 - 3.0 feet per second (80-90 cm/sec.) .

• Crankhandle speed: 55-65 rpm.

• Each complete revolution of the crankhandle causes the

impeller to rotate 7 1/2 turns.

Flow rate adjuster

setting # 6 (full open)

Pounds/Kg Delivered/

per minute

7.44 / 3,37

10.0 / 4,54

2.0 / 0,91

Flow rate adjuster

setting # 3 (middle)

Pounds/Kg Delivered/

per minute

4.4 / 2,0

3.75 / 1,70

10.0 / 4,54

Cran-

king

RPM

55-60

55-60

55-60

Pelletized

Fertilizer

Ø 2-3,5 mm

Ø 2-5 mm

Grass seed