3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

Quick Start Guide

Quick Start Guide

Quick Start Guide

SOLO Temperature Controller

SL4896 Series

SOLO

AutomationDirect’s SOLO is a single loop dual output temperature controller that can control both heating and

cooling simultaneously. There are four types of control modes: PID, ON/OFF, Manual, and Ramp / Soak control.

Depending upon the particular model of controller, the available outputs include relay, voltage pulse, current,

and linear voltage. There are up to three alarm outputs available to allow seventeen alarm types in the initial

setting mode. SOLO can accept various types of thermocouple, RTD, or analog inputs, and has a built in RS-485

interface using Modbus slave (ASCII or RTU) communication protocol.

Other features include:

• 1/8 DIN panel size

• 2 line x 4 character 7-segment LED display for Process Value (PV): Red color, and Set Point (SV): Green color

• Auto Tuning (AT) function with PID control

• Selectable between °C and °F for thermocouple or RTD inputs

• Two event inputs

• 0 to 50 °C (32 to 122 °F) operating temperature range

• UL, CUL and CE agency approvals

General Description

Specifications

Output Specifications

Part Number

Input Voltage

Output #1

Output #2 / Alarm #3*

Alarm #1

Alarm #2

SL4896-RRE

110 - 240 VAC

Relay - SPDT

Relay - SPDT

Relay - SPST

Relay - SPST

SL4896-VRE

110 - 240 VAC

Voltage Pulse

Relay - SPDT

Relay - SPST

Relay - SPST

SL4896-CRE

110 - 240 VAC

Current

Relay - SPDT

Relay - SPST

Relay - SPST

SL4896-LRE

110 - 240 VAC

Linear Voltage

Relay - SPDT

Relay - SPST

Relay - SPST

SL4896-RRE-D

24 VDC

Relay - SPDT

Relay - SPDT

Relay - SPST

Relay - SPST

*Output #2 can be configured as control output #2 or as Alarm #3

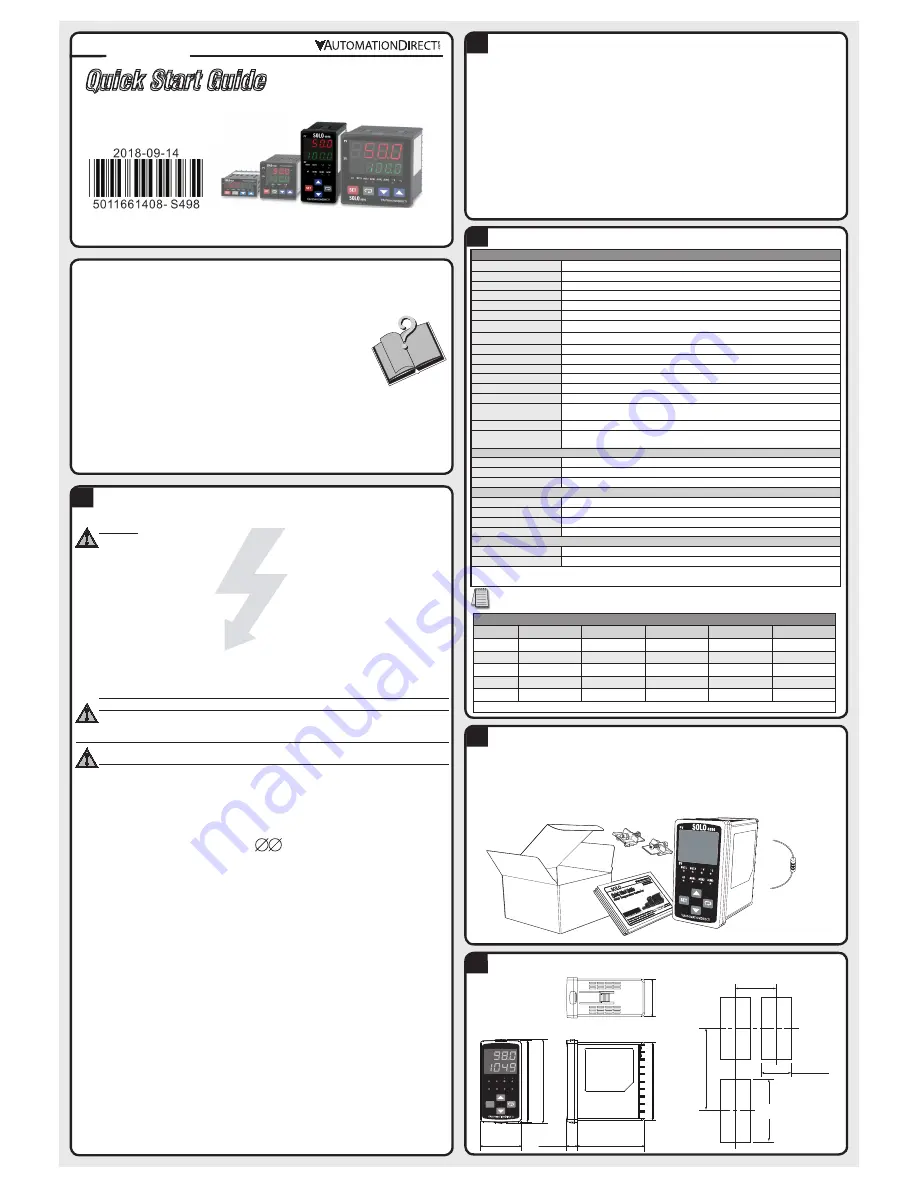

Box Contents and Unpacking Instructions

1.73”

(44.0 mm

)

3.58”

(91.0 mm

)

3.12”

(79.2 mm)

0.50”

(12.8 mm)

3.87

”

(98.2 mm

)

3.77”

(95.7 mm

)

1.89”

(48.0 mm)

PV

SV

OUT1 OUT2

ALM1

AT

SET

ALM2 ALM3

F

C

4896

SOLO

Controller and Panel Cutout Dimensions

2.36"

[60.0 mm]

4.72"

[120.0 mm

]

1.75"

[44.5 mm]

+0.02

-0

+0.6

-0

3.60"

[91.4 mm]

+0.02

-0

+0.6

-0

(Min.)

(M

in.)

2

3

4

5

This Quick Start Guide provides basic information on setting up the SOLO temperature controller.

For advanced setup and communication control as well as free configuration software visit the

AutomationDirect web site at www.AutomationDirect.com.

SL4896

Series

Mounting Brackets

and Hardware

SL4896 Temperature

Controller

SL4896

Quick Start Guide

• Unpack the SOLO temperature controller from its shipping carton. Included in the carton is the temperature

controller, mounting brackets plus hardware and this Quick Start Guide.

• Inspect all equipment for completeness. If anything is missing or damaged, immediately call the

AutomationDirect

returns department @ 1-800-633-0405.

• Inspect the part number to ensure the model received matches the output type required.

*Note: The supplied 249 ohm resistor should be installed as shown in the terminal wiring diagrams

in section 7 for current input operation.

249 ohm

resistor

Specifications

Input Power Requirements

100 to 240 VAC 50 / 60 Hz or 24 VDC

Operation Voltage Range

85 to 264 VAC or 21.6 to 26.4 VDC

Power Consumption

5 VA Max

Memory Protection

EEPROM 4K bit, number of writes 100,000

Control Mode

PID, ON/OFF, Ramp / Soak control or Manual

Input Accuracy

Less than ± 0.2% full scale (except thermocouple R, S, & B types) Max ± 3° (thermocouple R, S, & B types)

Vibration Resistance

10 to 55 Hz, 10 m/s

2

for 10 min, each in X, Y and Z directions

Shock Resistance

Max. 300 m/s

2

, 3 times in each 3 axes, 6 directions

Ambient Temperature Range

32°F to 122°F (0°C to 50°C)

Storage Temperature Range

-4°F to 149°F (-20°C to 65°C)

Altitude

2000m or less

Relative Humidity

35% to 80% (non-condensing)

RS-485 Communication

Modbus slave ASCII / RTU protocol

Transmission Speed

2400, 4800, 9600, 19.2K, 38.4K bps

IP Rating

IP65: Complete protection against dust and low pressure spraying water from all directions.

(inside suitable enclosure)

Agency Approvals

UL, CUL, CE (UL file number E311366)

Pollution Degree

Degree 2 - Normally, only non-conductive pollution occurs.

Temporary conductivity caused by condensation is to be expected.

Input Types

• Thermocouple*

K, J, T, E, N, R, S, B, L, U, TXK (Sampling Rate: 400 ms / per scan)

• Platinum RTD

3-wire Pt100, JPt100 (Sampling Rate: 400 ms / per scan)

• Analog

0-50 mV, 0-5V, 0-10V, 0-20 mA, 4-20 mA (sinking) (150 ms per scan)**)

Control Output Options

• Relay (R)

SPDT max. resistive load 5A @ 250 VAC

• Voltage Pulse (V)

DC 14V Max, output current 40mA Max

• Current (C)

DC 4-20 mA output (sourcing) (Load resistance: Max 600

Ω

)

• Linear Voltage (L)

DC 0-10V (Load resistance Min 1K

Ω

)

EVENT Inputs

• Event1

Normally open contact, for output control

• Event2

Normally open contact, for switching setting value

*Note: Use only ungrounded thermocouples.

** Analog input impedance: 1.8M

Ω

Safety Information

WARNING:

To minimize the risk of potential safety problems, you should follow all applicable local and

national codes that regulate the installation and operation of your equipment. These codes vary from area to

area and it is your responsibility to determine which codes should be followed, and to verify that the equip-

ment, installation, and operation are in compliance with the latest revision of these codes.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable codes

and standards. We do not guarantee the products described in this publication are suitable for your particular

application, nor do we assume any responsibility for your product design, installation, or operation.

If you have any questions concerning the installation or operation of this equipment, or if you need additional

information, please call us at 1-800-633-0405 or 770-844-4200.

This publication is based on information that was available at the time it was printed. At

Automationdirect.

com®

we constantly strive to improve our products and services, so we reserve the right to make changes to

the products and/or publications at any time without notice and without obligation. This publication may also

discuss features that may not be available in certain revisions of the product.

WARNING! Electric shock danger

1. To prevent electric shock, do not touch the AC terminals while the power is supplied to the controller.

This controller is an open-type temperature controller. Make sure to evaluate any dangerous application in

which a serious human injury or serious property damage may occur.

1. Always use recommended solder-less terminals: Fork terminal with insolation (M3 screw, width is 7.0mm, hole

diameter 3.2mm). Screw size: M3 x 6.5 (With 6.8 x 6.8 square washer). Recommended tightening torque: 0.4 Nm

(4kgfcm). Applicable wire: Solid/twisted wire of 2 mm, 12AWG to 24AWG. Choose AutomationDirect part numbers

BM-00120, BM-00220 or BM-00320 depending on wire size. Be sure to tighten them properly.

2. Protect the controller from dust or foreign objects to prevent controller malfunction.

3. Do not modify or disassemble the controller.

4. Do not connect anything to the “Not used” terminals.

5. Make sure all wires are connected correctly.

6. Do not install and/or use the controller in places subject to: (a) Dust or corrosive gases and liquid (b) High humidity

(c) Vibration and shock (d) EMI / RFI (e) high temperature.

7. Turn power off when wiring or changing a temperature sensor.

8. Be sure to use wires that match the thermocouple types when extending or connecting the thermocouple wires.

9. Use wires with correct resistance when extending or connecting a platinum resistance thermometer (RTD).

10. Keep the wire as short as possible when wiring a platinum resistance thermometer (RTD) to the controller and

route power wires as far as possible from load wires to prevent interference and induced noise.

11. This controller is an open-type unit and must be placed in an enclosure away from high temperature, humidity,

dripping water, corrosive materials, airborne dust and electric shock or vibration.

12. Make sure power cables and signals from instruments are all installed properly before energizing the controller,

otherwise serious damage may occur.

13. To prevent electric shock, do not touch the terminals in the controller or try to repair the controller when power

is applied.

14. Use a soft, dry cloth to clean the controller. Do not use acid or alkaline liquids for cleaning.

15. This instrument is not furnished with a power switch or fuse. Therefore, if a fuse or power switch is required,

install the protection close to the instrument. Recommended fuse rating: Rated voltage 250 V, Rated current 1

A. Fuse type: Time-lag fuse

16. Note: This controller does not provide overcurrent protection. Use of this product requires that suitable overcur-

rent protection device(s) must be added to ensure compliance with all relevant electrical standards and codes.

(Rated 250 V, 15 Amps max). A suitable disconnecting device should be provided near the controller in the

end-use installation.

1

Product Support and Configuration Software

• For product support, specifications, and installation troubleshooting, a complete

User Manual can be downloaded from the On-line Documentation area of the

AutomationDirect

web site.

• For additional technical support and questions, call our Technical Support team

@ 1-800-633-0405 or 770-844-4200.

• Configuration software for the SOLO controller is available for free down-

load at

www.AutomationDirect.com

. The software allows communication

and programming for up to four controllers at the same time. Parameters,

process values, set points and temperature changes can be monitored with

the software. The setup data can be uploaded to the user’s PC via RS-485

communication. The user can monitor the temperature changes of the

controllers from the “PV Monitor” Display.

16 18