30

IMPORTANT!

The connection must be performed by an

authorised person according to the relevant standards.

•

This appliances is suitable for us with Natural Gas or

ULPG. The cooktop is shipped from the factory set

and adjusted for Natural Gas. It can be converted for

use with ULPG following the instructions within this

manual.

•

The connection must be made at the rear of the

appliances. Ensure that the pipe does not cross

the cooker.

INSTALLATION WITH A FLEXIBLE HOSE ASSEMBLY

•

If this appliance has to be installed with a hose

assembly, the installer shall refer to the network

operator or gas supplier for confirmation of the gas

type, if in doubt.

•

When used with a flexible hose, the connector on the

wall should be between 450mm to 500mm from the

floor and 200 mm to 300 mm from the left-hand side

of the appliance as viewed from the front. The hose

connection on the appliance shall face downwards.

•

It is important that the hose does not come in contact

with the metal of the appliance and is secured as per

appropriate gas installation codes. The stabilising

chain (installation of the chain referred to within this

manual) should be installed to restrict movement of

the appliance to no more than 80% of the length of

the flexible gas hose. The chain should be attached

securely to the product where shown, and on the wall.

•

Flexible hose assemblies should be AS/NZS 1869

Class B or Class D certified. The thread connection

shall be Rp ½” (ISO 7-1) male.

•

The hose assembly shall be as short as practicable

and comply with relevant AS5601 / NZS5261

requirements.

IMPORTANT!

After connection the installer must check

that the hose is not kinked, subjected to abrasion or

permanently deformed. The installer must check also that

the hose is not near (or in contact) with any hot surfaces.

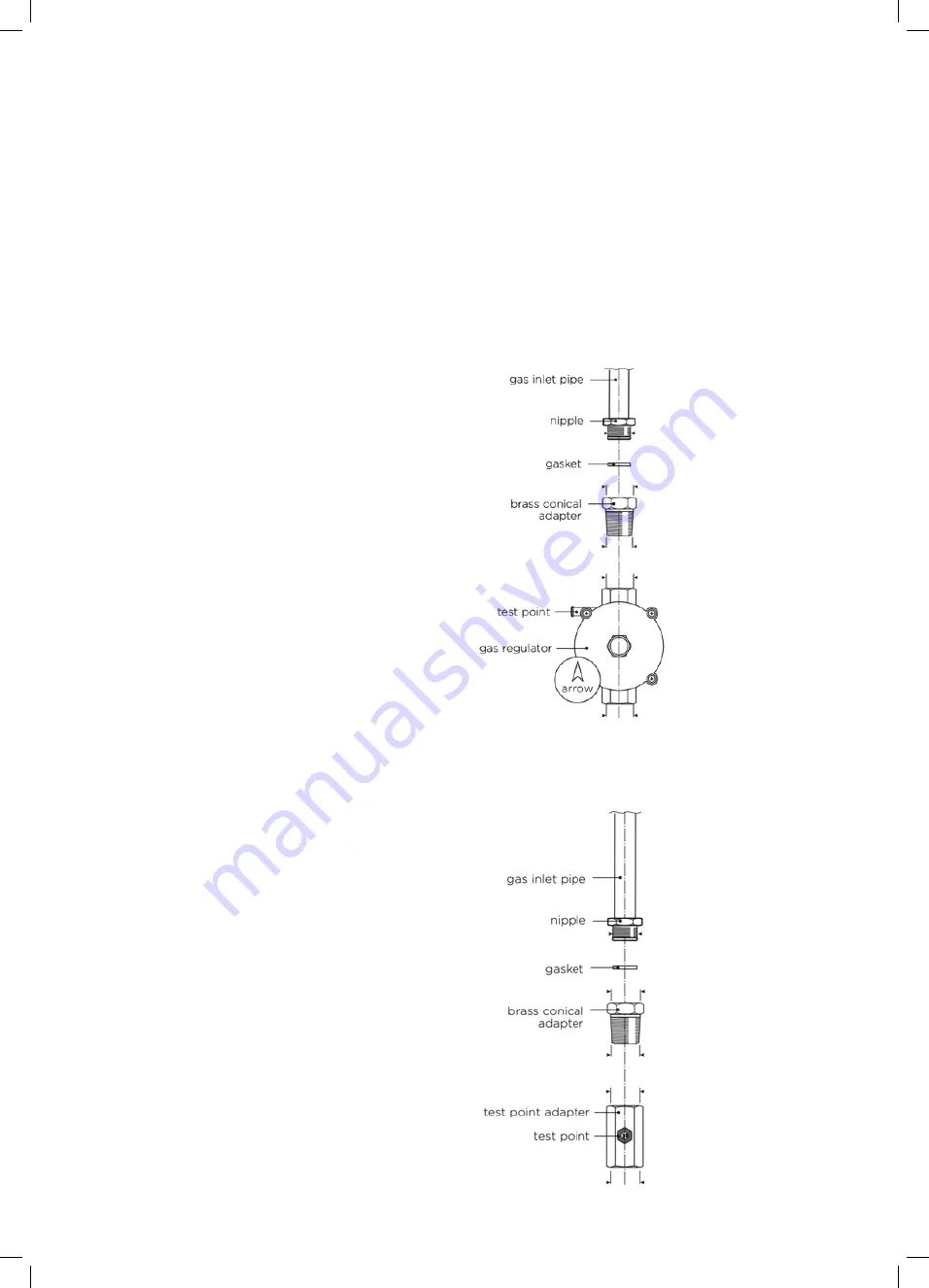

GAS CONNECTION SPECIFICATION

IMPORTANT!

Check the correct positioning of the gas

regulator. The arrow on the back of the gas regulator

must be oriented toward the connector.

Natural Gas

Adjust to obtain a test point pressure of 1 kPa

with all the burners operating at highest setting.

ULPG

Ensure the supply pressure is regulated to 2.75 kPa,

with all the burners operating at highest setting.

IMPORTANT! Check the correct positioning of the gas regulator. The arrow on the back of the

gas regulator must be oriented toward the connector.

NG

Adjust to obtain a test point pressure of 1 kPa with all the burners operating at highest setting.

ULPG

Ensure the supply pressure is regulated to 2.75 kPa, with all the burners operating at highest

setting.

GAS CONNECTION

IMPORTANT! The connection must be performed by an authorised person according to the

relevant standards.

Natural Gas

IMPORTANT! Check the correct positioning of the gas regulator. The arrow on the back of the

gas regulator must be oriented toward the connector.

NG

Adjust to obtain a test point pressure of 1 kPa with all the burners operating at highest setting.

ULPG

Ensure the supply pressure is regulated to 2.75 kPa, with all the burners operating at highest

setting.

GAS CONNECTION

IMPORTANT! The connection must be performed by an authorised person according to the

relevant standards.

Natural Gas

Gas Connection