Hot water pip ing must be supported by suitable hangers or

floor stands, NOT by the boiler. Copper pipe systems will be

subject to considerable expansion and con trac tion. Rigid pipe

hangers could allow the pipe to slide in the hanger resulting in

noise transmitted into the system. Padding is recommended

on rigid hangers installed with a copper system. The boiler

pressure relief valve must be piped to a suitable floor drain.

See the relief valve section on page 23 of this manual.

CAUTION

A leak in a boiler system will cause the

system to intake fresh water constantly,

which will cause the tubes to accumulate

a lime/scale build up. This will cause a

NON-WARRANTABLE FAILURE

.

Water Connections

Heating Boilers with inputs of 45,000 - 260,000 Btu/hr have

1 1/2" NPT inlet and outlet connections.

CAUTION

Field installed reducing bushings may

de crease flow re sult ing in boiler noise or

flashing to steam.

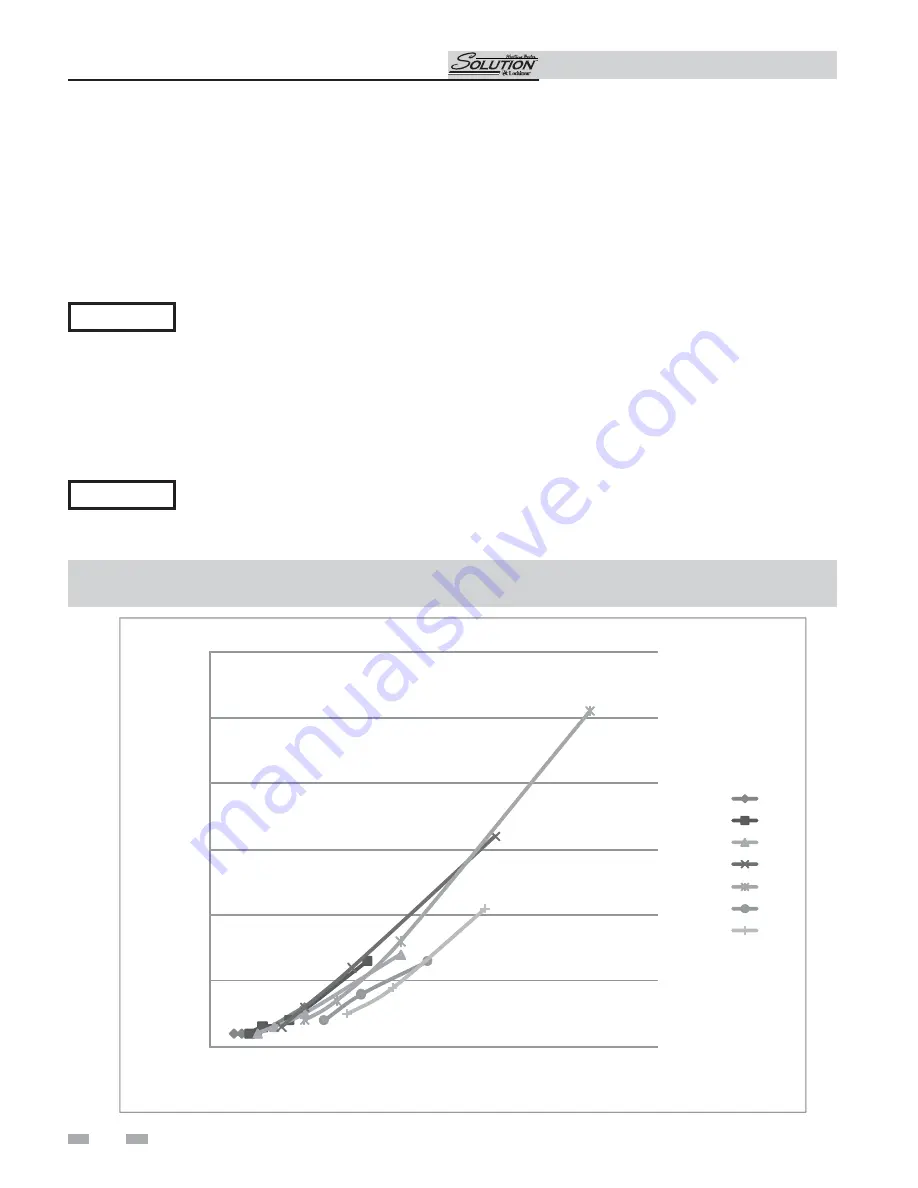

Circulator Pump Requirements

This is a low mass, high efficiency hot water boil er which

must have adequate flow for quiet, efficient op

er

a

tion.

The boiler circulating pump must be field supplied. The

boiler circulator pump must operate con tin u ous ly while the

boiler is firing. Pump selection is critical to achieve proper

op er a tion. A pump should be selected to achieve proper system

design water temperature rise. A heat ex

chang

er pressure

drop chart (Table 4C) is provided to assist in proper pump

selection. Also provided is a System Temperature Rise Chart

(Table 4B on page 25). This table provides GPM and boiler

head-loss at various temperature rises for each boiler based on

Btu/hr input. Temperature rise is the difference in boiler inlet

temperature and boiler outlet temperature while the boiler is

firing.

Example:

The boiler inlet tem per a ture is 160°F and the boiler

outlet temperature is 180°F, this means that there is a 20°F

tem per a ture rise across the boiler.

TABLE - 4C

HEAT EXCHANGER PRESSURE DROP CHART

0

1

2

3

4

5

6

0

5

10

15

20

25

30

35

FT

/H

D

Gallons per Minute

CB 45

CB 75

CB 90

CB 135

CB 180

CB 215

CB 260

4

Water connections

26

Installation & Service Manual

Summary of Contents for CBN045

Page 51: ...51 Notes ...