GRW

Installation

10

GRW - Manual

|

SolutionAirGroup.com

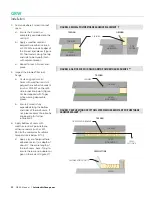

FIGURE 9: SECTION PLACEMENT

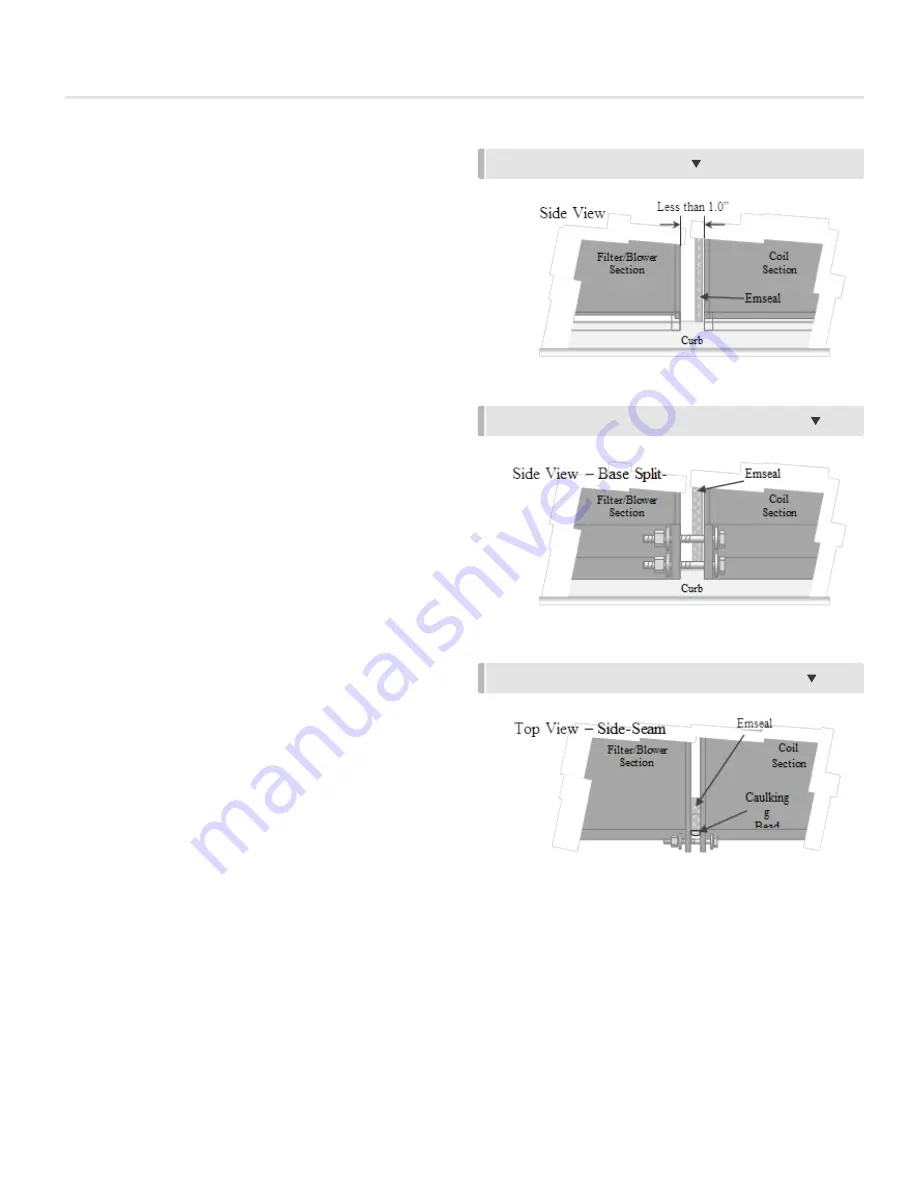

FIGURE 10: POSITIONED SECTION FASTENING BOLTS

FIGURE 11: TIGHTENED SECTION FASTENING BOLTS

14. Install the blower-section, by lowering it down within

1” of the coil-section.

NOTE:

the blower-section must be lowered into the

coil-section receiver flange, which will aid in guiding

the sections together. If the gap between the sections

is more than 1.0”, the blower section cannot be pulled

into place without damaging the coil-section receiver.

a) A centering-punch shall be used (through the

lifting-lug bolt-holes) to guide and align the

sections together.

b) Ensure less than a 1.0” gap between the blower

and coil sections (Figure 9).

c) Fasten the blower and coil sections together (with

the provided stainless steel hardware).

i)

Insert 2” stainless steel bolts (with washers)

into the holes on the coil-section lifting lug,

through to the matching blower section holes

(Figure 10).

ii) Finger-tighten a stainless steel nut (backed by

a washer) onto the 4 bolts, as illustrated above.

iii) Install and finger-tighten the supplied side-

flange bolts (stainless steel 1” bolts, washers,

and nuts), starting at the base on both sides,

moving towards the top of the unit.

iv) Apply a light bead of outdoor-rated

polyurethane caulking to the side-seams,

ensuring the caulking covers the Emseal

and touches the aluminum on both sections

(Figure 11).

v) Gradually bring the units together by

tightening the 4 lifting-lug nuts (2 on each

side), until there is less than a 1/8” gap

between the lifting lugs.

vi) Once the four lifting-lug nuts are tight, tighten

the side-flange bolts from bottom to top.

I) Clean off any sealant squeeze-out with a

dry disposable rag.

15. Once complete, repeat the above steps for the filter-

section.