44

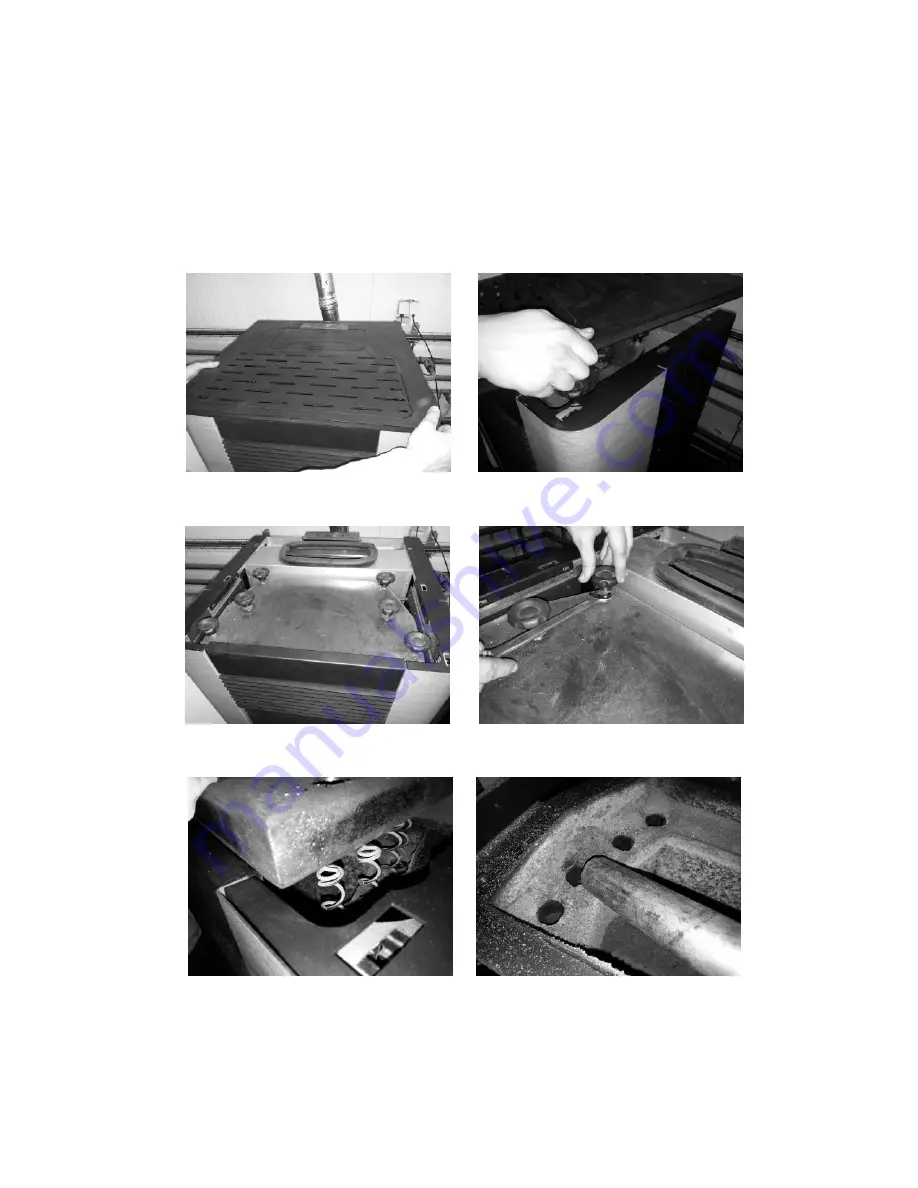

For the backboiler unit, the procedure involves cleaning the air flow pipes and

turbulators. To do this, open the lid on the top of the unit (Figure 51-a and b) and remove

the four sticks (Figure 51-c and 51-d). Then pull the turbulators up (Figure 51- e). A

vacuum cleaner must be used to clean this area (Figure 51-f) and the interior of the

pipes can be cleaned with a steel brush. The turbulators that are removed must also be

cleaned with a steel brush.

To reinstall the turbulators, execute in reverse the above procedure shown in the figures.

a)

b)

c) d)

e) f)

Figura 30 – Cleaning of gas passageways and turbulators

Summary of Contents for Douro 12kW

Page 13: ...12 a b ...

Page 50: ...49 ...

Page 51: ...50 ...

Page 52: ...51 ...

Page 58: ...57 18 Electrical Diagram of the Free Standing Fire Unit Figure 40 Electrical diagram ...

Page 70: ...69 21 Annexes 21 1 Flow chart Lighting ...

Page 71: ...70 ...

Page 72: ...71 Disabling ...