10

5.2.

Installation of ducts and smoke exhaust systems:

The construction of the gas exhaust pipe must be suitable for this purpose in

accordance with the local requirements and the applicable regulations.

Important! An inspection T- with a hermetic cap should be inserted at the exit

of the stove tailpipe to allow regular inspection or discharge of heavy dust and

condensate.

As shown in Figure 6, the exhaust duct shall be carried out in such a way that

cleaning and maintenance is ensured by inserting the inspection points.

- In operating conditions at rated power, it must be ensured that the draught of the

combustion gases must cause a depression of 12 Pa, measured 1 meter above the

smoke outlet.

The stove can't share the chimney with other equipment.

The pipes outside the place of use must be double insulated in stainless steel, with

an internal diameter of 80 mm.

The smoke exhaust pipe can generate condensation, in which case it is advisable to

establish suitable condensate collection systems.

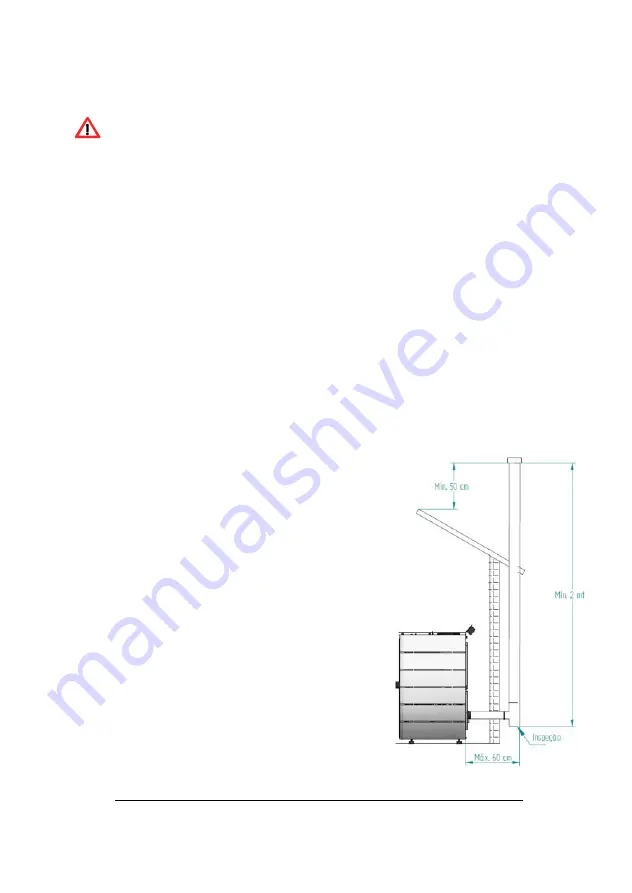

5.3.

Installation without chimney

The installation of the pellet stove when there is no

chimney should occur, as in figure 6, bringing the

smoke exhaust pipe (with minimum internal

diameter of 80 mm) directly out and above the

roof.

Insulated double-walled stainless steel pipes

should be used properly anchored to prevent

condensation phenomena.

Provide a T at the base of the pipework for periodic

inspections

and

annual

maintenance,

as

exemplified in figure 5.

.

Figure 5 – Side view of the installation without chimney, with example of the inspection point

Summary of Contents for K50

Page 44: ...43 ...

Page 45: ...44 ...

Page 46: ...45 ...

Page 59: ...58 20 2 Fluxograme Ignition ...

Page 60: ...59 ...