SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Pulper operates

but pulping rate

is low.

1. Plugging of sizing

ring.

2. Worn or missing

impeller blades.

3. Worn or missing

stationary blades.

4. Excessive foaming.

5. Sluggish vortex due

to:

a. Too little water in

Pulper.

b. Overload of waste.

6. Clogged or worn

pump.

7. Clogged slurry lines.

1. Check stationary blades and ears. If dull, replace.

Refer to Pulper maintenance section. Check water

level control - it may be adjusted too low. See

previous section.

2. Refer to Pulper maintenance section for replacement

procedure.

3. Adjust or replace blades in accordance with Pulper

maintenance section of manual.

4. Add a de-foamer or any other suitable commercial

preparation. (See Section 5.)

5. (See below)

a. See Previous section.

b. Revise waste feeding rate (see Feeding

Instructions, Section 4).

6. See pump section for require corrective action.

7. Check individual cleanouts for loss of pressure to

locate blockage. Remove blockage.

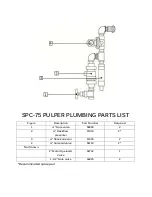

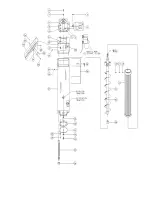

Summary of Contents for SPC-75S

Page 12: ...Installation ...

Page 16: ...MOUNTING DETAIL OF TROUGH ...

Page 21: ...FOR REFERENCE ONLY ...

Page 22: ...Start Up ...

Page 26: ...Operation ...

Page 32: ...CLEANING YOUR SYSTEM ...

Page 38: ...MAINTENANCE ...

Page 49: ...TROUBLESHOOTING ...

Page 56: ...REPLACEMENT PARTS EXPLODED VIEWS ...

Page 57: ......

Page 60: ......

Page 62: ......