SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Hydra-

Extractor

stops

frequently.

1. Worn Screw.

1. Replace screw.

Heavy flow from

overflow pipe.

1. Excessive foaming

2. Blockage of return

line.

3. Improper Return

water flow.

1. Add a de-foamer. (See Section 5)

2. Check individual cleanouts to locate blockage.

Locate blockage.

Remove blockage.

3. Readjust throttling valves.

Excessively wet

pulp discharge

from Hydra-

Extractor

.

1. Blockage of screen.

2. Worn screw and

brush.

1. Clean the Hydra-Extractor

screen. Refer to Hydra-

Extractor

Maintenance Section of the manual.

2. Send worn screw back to SOMAT Company for repair.

Remove screw and replace. Refer to Hydra-

Extractor

Maintenance Section of this manual.

SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Hydra-

Extractor

stops

frequently.

1. Worn Screw.

1. Replace screw.

Heavy flow from

overflow pipe.

1. Excessive foaming

2. Blockage of return

line.

3. Improper Return

water flow.

1. Add a de-foamer. (See Section 5)

2. Check individual cleanouts to locate blockage.

Locate blockage.

Remove blockage.

3. Readjust throttling valves.

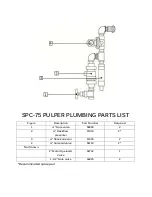

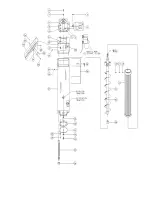

Summary of Contents for SPC-75S

Page 12: ...Installation ...

Page 16: ...MOUNTING DETAIL OF TROUGH ...

Page 21: ...FOR REFERENCE ONLY ...

Page 22: ...Start Up ...

Page 26: ...Operation ...

Page 32: ...CLEANING YOUR SYSTEM ...

Page 38: ...MAINTENANCE ...

Page 49: ...TROUBLESHOOTING ...

Page 56: ...REPLACEMENT PARTS EXPLODED VIEWS ...

Page 57: ......

Page 60: ......

Page 62: ......