ASSEMBLY INSTRUCTIONS

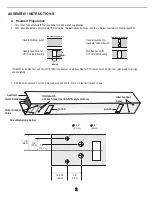

A. Headrail Preparation

1. Cut or specify headrail width that is suitable for blind or shade application.

2. Cut or punch headrail to accomodate CTS 40 cradle. The illustrations below portray two different examples of headrail punches.

3. Drill the holes necessary for the motor and plug end and for access to the limit switch screws.

Headrail punched for

standard "Ladder Braids"

Modified punch for

CTS 40 cradle bearing

Top view of headrail

Headrail without punch

Headrail punched for

CTS 40 cradle bearing

Top view of headrail

1.5"

(38mm)

.787"

(20mm)

punch

punch

idler bracket

holes

limit switch

access holes (for non-RTS style motors)

See dimensions below

motor bracket

holes

motor bracket

headrail

1 1/8"

(28.5)

7/8"

(22.2)

1/2"

(12.7)

1 25/32"

(45.2)

1/2"

(12.7)

3/16"

(5 mm)

1/4"

(6 mm)

*SOMFY can provide Tool and Die (#1781099) to enable accurate punching for CTS components. Contact our sales group for pricing

and availability.

2