Symbol description: “

☆

” means HY, “▲” means alarm value, “ ” means SV value

7

8

9

10

11

12

SV

SV

SV

SV

SV

SV

SV-AL1

SV-AL1

SV-AL1

SV+AL2

SV+AL2

SV+AL2

AL2

AL2

AL2

AL1

AL1

AL1

1

2

4

5

6

SV+AL

SV+AL

SV-AL

SV-AL

SV

SV

SV+AL

SV-AL

AL

SV

SV

SV

SV

PV

PV

PV

PV

PV

PV

PV

PV

PV

PV

PV

PV

AL

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

▲

▲

▲

▲

▲

▲

▲

▲

△

△

△

☆

▲

△

△

△

△

▲

▲

△

▲

▲

△

▲

▲

△

▲

▲

▲

▲

△

△

▲

SV

SV

SV

SV

SV

SV

SV-AL1

SV-AL1

SV-AL1

SV+AL2

SV+AL2

SV+AL2

AL2

AL2

AL2

AL1

AL1

AL1

2

3

SV+AL

SV+AL

SV-AL

SV-AL

SV

SV

SV+AL

SV-AL

AL

SV

SV

SV

SV

PV

PV

PV

PV

PV

PV

PV

PV

PV

PV

PV

PV

AL

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

▲

▲

▲

▲

▲

▲

▲

▲

△

△

△

△

☆

▲

△

△

△

△

▲

▲

△

▲

▲

△

▲

▲

△

▲

▲

▲

▲

△

△

▲

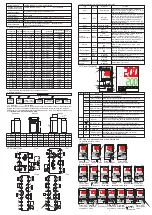

(1) Alarm parameters and output logic diagram:

Alarm

code

Alarm mode

Alarm output

(

AL1 & AL2 are independent from each

)

Image:the hatched section means the alarm action

High limit absolute value

alarm

Low limit absolute value

alarm

※

High limit deviation

value alarm

※

Low limit deviation value

alarm

※

High/low limit deviation

value alarm

※

High/low limit interval

value alarm

Alarm

code

Alarm mode

The below two alarm parameters(AL1,AL2) are used in

combination, AL1 alarm output, AD2 must be set as 0

High and low limit absolute

value interval alarm

※

High and low limit deviation

value interval alarm

※

High limit absolute value

and low limit deviation value

interval alarm

※

High limit deviation value

and low limit absolute value

interval alarm

High/low limit absolute value

alarm

High/low limit deviation value

alarm

※

For deviation alarm, if alarm value is set as a negative number, it will be used as an absolute

value.

No.

Name

Symbol

Illustration

Setting range

Factory

setting

1

2

4

AL1

HY1

AD1

(

1

)

AL2

HY2

AD2

(

1

)

FL

~

FH

0

~

1000

0

~

12

FL

~

FH

0

~

1000

0

~

6

-1999

~

9999

10

1

3

5

1

4

0

6

5

OT

0

~

5

INP

K1

1

0

~

9999

120

1

~

200

20

4

~

200

20

PC

10.0

OVS

0

~

9999

5

DB

-1000~1000

5

LCK

0~9999

0

0

~

9999

30

8

9

0

~

9999

30

A-M

AUTO~AM

AUTO

10

3

AD1

(

1

)

PS

0

~

12

3

7

I

CP

CP1

0.1

~

100.0

OVS

LCK

P

12

13

14

15

16

17

18

19

11

D

1st alarm hystersis

2nd alarm value,

2nd alarm hystersis

2nd alarm mode

OUT1 control cycle, 1: SSR control output,

4-200: relay control output. Unit: s

OUT2 relay output cycle. Unit: s

OUT2 cooling proportionality coefficient, the higher of

value,the stronger of cooling

ON/OFF control hystersis(positive and negative

numbers work the same); when OT=3, it is the dead

zone for cooling control(positive and negative

numbers work differently);after change the INP

setting, please change this parameter according to

the decimal point position.

Lock function. 0001:SV value can’ t be modified.

0010: menu set value can be checked only, can’ t

be modified. 0033: enter to advanced menu.

0123: menus reset to factory setting.

Overshoot limit, during PID control process, when

PV(measured value) > SV(set value) + OVS

(overshoot limit), force to close output. The smaller

this value is, the smaller the PID adjustment range

is, the worse the control stability is. Please set the

appropriate value according to the actual situation.

Differential time, the greater the value is, the stronger

the differential actiontion is, otherwise, it is weeker.

When D=0, no differential action. Set D=0 when

controlling fast systems, e.g., pressure, speed; unit: s

Integral time, the smaller the value is, the stronger the

integral action is, otherwise, it is weeker. When I=0,

no integral action, unit: s.

Proportional band, the smaller the value is, the faster

the system responds, otherwise, it is slower. When

P=0, no PID control, unit same as PV

Amend value, display value= actual measured value

+ amend value

Control mode, 0:ON/OFF heating control, relevant

parameter: DB.

1: PID heating control, relavant parameters:

P, I, D, OVS, CP, ST, SPD, PDC.

2: ON/OFF cooling control, relevant parameter DB;

need to set PT when it is used for compressor control.

3:PID heating & cooling control (cooling control OUT2

will output through AL1 relay), relevant parameters: P,

I, D, OVS, CP, CP1, PC, DB, ST, SPD, PDC.

4: Over temperature cooling output

,

relevant

parameter: DB

5. PID cooling, relevant parameter: P, I, D, OVS, CP,

ST, SPD, PDC.

Optional input signal. Note: after selecting the signal,

pls properly set below relevant parameters: SV, AL1

,

HY1

,

AL2

,

HY2

,

P

,

OVS

,

DB.

Auto-manual control switch, AUTO(0): auto control

only; MAN(1): manual control only;

AM(2): auto-manual shortcut switch

refer to input

signal para-

meters table

(page 3)

1st alarm mode. Note:when AL1 is used as OUT2(co-

oling output), should set AD1=0(close alarm function).

When AD1>6, 2nd alarm function is invalid.

No.

Name

Symbol

Illustration

Setting range

Factory

setting

IX. Menu Illustration

1. Regular Menu

:

No mater what model, what control mode it is, it will always display these parameters.

:

According to different model, control mode, these parameters will be hidden.

1st alarm value, note: the minus is dealed as absolute

value when it is set as deviation alarm. Refer to

(1) Alarm parameters and output logic diagram

5

6

2

、

Operation examples

1. Set target

temperature

SV=100

2

、

Advanced Menu

22

20

21

ACT

Control execution type. 0: relay or SSR output.

1:SSR output (Code type M select this item).

2: 4~20mA control output, 3: 4~20mA retransimition

output for size 4/7 products. Note:For size 6/8/9

products, when this menu is set as 0 or 1, 4-20mA

output is used as retransimition output.

0~2

(

6/8/9 size

)

0~3

(

4/7 size

)

0

AE1

1st alarm extensions function, refer to (2) alarm

extension function table

0~5

0

0~5

0

0~3

0

AE2

DP

2nd alarm extensions function, refer to (2) alarm

extension function table

Decimal point setting, maximum 1 decimal place for

TC & RTD input

23

2. Set menu

INP=K

3. Set menu

OT=0

4. Set menu

DB=2

5. Set menu

ACT=0

6. Set menu

AL1=110

7. Set menu

HY1=5

8. Set menu

AD1=1

1. Set target

temperature

SV=150

2. Set menu

INP=pt

3. Set menu

OT=1

4. Set menu

OVS=5

5. Set menu

ACT=0

6. Set menu

AL1=5

7. Set menu

HY1=7

8. Set menu

AD1=3

25

→

→

→

150

inp

pt

ot

1

5

→

ACT

0

→

AL1

5

→

HY1

7

→

AD1

3

1

)

Example 1, ON/OFF control

:

Sensor

:

K type, measure range -50~1300

℃

; target temperature: 100

℃

; control mode:

heatin; control requirement: ON/OFF control, when current temperature PV reaches 100

℃

,

stop heating; when PV is lower than 98

℃

, start heating again; control output: relay; alarm: 1

alarm, when PV>110

℃

, alarm output on; when PV<105

℃

, alarm output off.

2

)

Example 2, PID control:

Sensor: PT100, measure range -200~600

℃

; target temperature: 150

℃

; control mode:

heating; control requirement: PID control (note: in order to get stable temperature control,

please use the auto-tuning function when the controller is powered on for the first time; if the

temperature control is stable after the auto tuning, there is no need to repeat this step in the

future usage.); control output: SSR; alarm: 1 alarm, when PV>SV+5

℃

, alarm output on,

when PV<SV-2

℃

, alarm output off.

25

→

→

→

100

inp

ot

0

db

2

→

ACT

0

→

AL1

110

→

HY1

5

→

AD1

1

42

43

45

CAL

CAH

VER

YES/OK

YES/OK

YES

YES

44

SSM

0

~

1

0

Software version, read only

Self-calibration low limit input operation, after adding

the low end signal to the signal input terminal, flash

YES to activate, after confirm and display OK, the

input signal low end calibration is completed.

Self-calibration high limit input operation, after adding

the high end signal to the signal input terminal, flash

YES to activate, after confirm and display OK, the

input signal high end calibration is completed.

Enable R/S key to switch RUN / STOP operation.

0: Forbidden 1: Enable This setting is only for

panel operation, not for communication operation.

CAE

0

(

N

)

1

(

Y

)

N

41

User self-calibration enable function, this parameter

is only for the input signals except TC/RTD;

Y:enable the self-calibration parameters;

N: don’ t use the self-calibration parameters.

No.

Name

Symbol

Illustration

Setting range

Factory

setting

27

28

FL

-50

FH

1200

29

30

31

32

33

34

35

BRH

OLH

ST

SPD

0.0

~

105.0

0~1

0~1

1200

100.0

BRL

FL~FH

FL~FH

OLL

0

0

0~6

N

PDC

FUZ

-5.0~100.0

-50

36

PT

0~9999

0

37

38

BAD

ADD

DTC

9.6

1

1~247

0

Modbus Communication ADD

39

40

0~2

0~2

N0

PRTY

PV fuzzy tracking value, properly set this value on

some occasions, it can get a more stable control

display value, this value is unrelated with actual

measured value. Note: after setting this value, when

alarm setting value is equal to SV set value, alarm

output operation is subject to actual measured value.

Set as 0 to close this function.

26

Filter coefficient, the higher of value, the stronger of

filter function

UT Temperature unit:

℃

: Celsius degrees.

℉

: Fahrenheit

degrees. Note: No unit for linear signal

(25)

℃

(25)

℃

(26)

℉

25

FT

0

~

255

10

(0~20)

DTR

0.0

~

2.0

(10)

1.0

24

0

0~2

Measuring range low limit and high limit.

For temperature sensor input, please keep the factory

setting value. For 4 ~ 20mA / 0 ~ 10V input, please

set the corresponding range for the low limit and the

high limit. For example, 0~10V corresponds to -20~50,

set FL to - 20, set FH to 50. Setting range:

-1999~9999, associated with DP decimal point menu.

4~20mA analog output low limit and high limit. For

example, 4~20mA corresponds to 0~100, set brL to 0,

set brH to 100. Note: it can be set as reverse analog

output, for example, 100~0 corresponds to 4~20mA.

Current control output low limit and high limit, only

valid for 4~20mA current control output. It is used to

limit the output current amplitude. For example, in the

control of frequency converter, if the motor cannot be

stopped, please set the output low limit OLL to 10%;

in heating control, if the user don’ t want full-power

output at the beginning of heating, please set the

output high limit OLH to 80%.

Compressor start delay time, unit: sec

Baud rate 0 (4.8): 4800

;

1 (9.6): 9600;

2 (19.2): 19200

Communication parity check setting

,

0

:

NO 1

:

ODD 2

:

EVEN

Communication data transport sequence 000;

1st bit function reserved; 2nd bit is byte sequence

exchange; 3rd bit function reserved.

Auto-tune activation after power-on, 0: work normally

after power-on, 1: automatically enter PID parameters

auto-tune status after power-on; long press “ AT ” key

to exit auto-tune.

PID control speed adjustment,option: 0 (N) no function,

1 (s) slow, 2 (ss) medium slow, 3 (SSS) very slow,

4 (F) fast, 5 (FF) medium fast, 6 (FFF) very fast

PID algorithm option: 0(FUZ): Advanced fuzzy PID

arithmetic; 1(STD): normal PID arithmetic

Refer to

measured

signal

parameter table

Refer to

measured

signal

parameter table

Refer to COMM.

protocol

note

③