The last toolbar option is for calibrating the locations of wells within a microtiter plate. If you

have changed dispensers, or have switched between 96- and 384-well microtiter plate types,

you will need to set the new starting location of the first well in the microtiter plate on the

system’s deck.

To do this, move to the A1 well position (which should be in the upper-right corner of the plate)

on the first microtiter plate (the one towards the rear of the system) and bring the dispenser

down into the well. Click on the

Set A1 Well Position

toolbar item to set the new A1 well

location. The positions of all of your specified solutions will be recalculated to match.

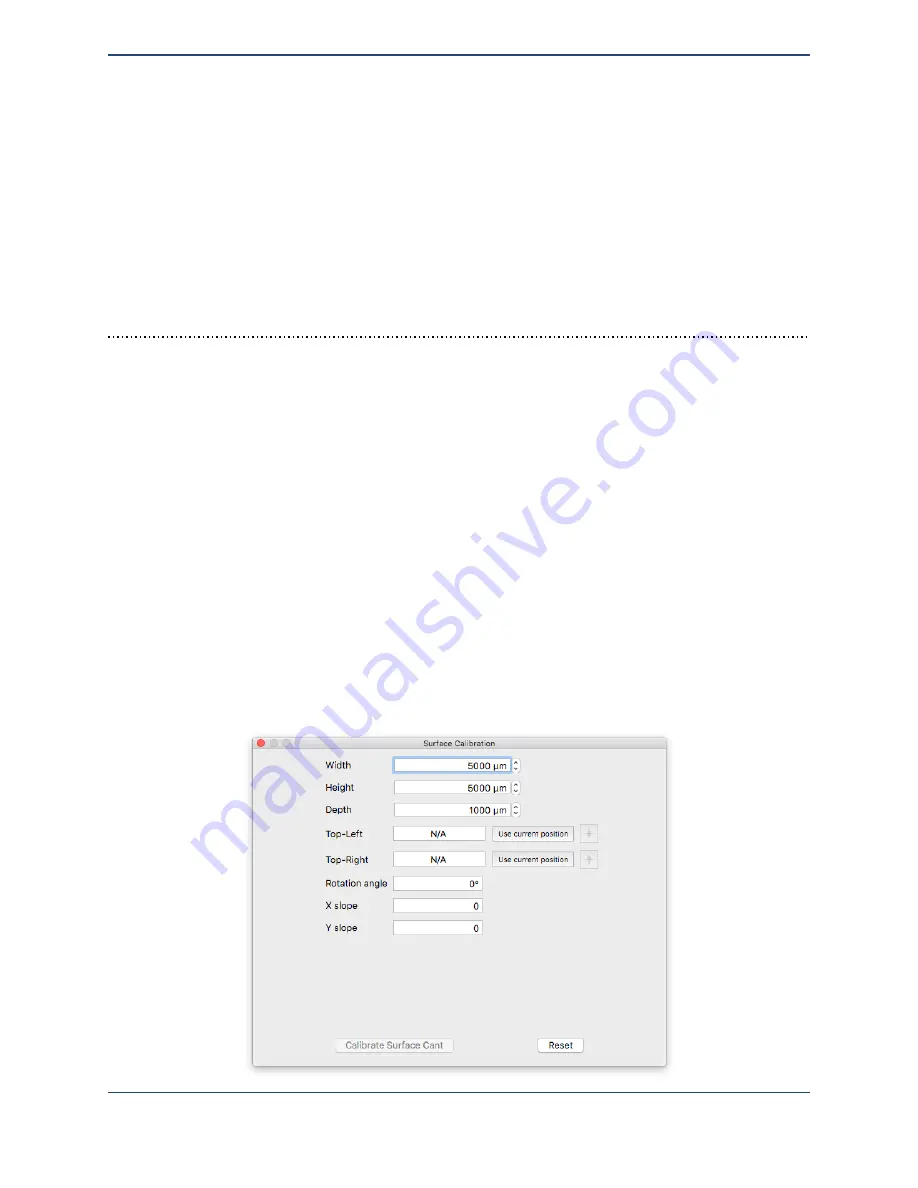

Surface cant calibration

The Microplotter ultrasonic dispensers have the capability of electronically sensing when their

tips have contacted a physical surface. This means that more reliable dispensing can occur and

the lifetime of a dispenser can be prolonged by preventing positioning overshoot that might

damage a dispenser’s fragile tip. The application of this surface sensing has been described in

the

Main interface

and

Robotic positioner settings

sections.

The ability of a Microplotter dispense head to electronically sense contact with the surface

allows the system to calibrate the cant of a flat surface. Every flat surface placed on the

substrate platen has some degree of tilt to it and even the slightest cant can cause a difference

in surface height great enough that the dispenser either misses the surface completely or

overshoots and shatters its tip. In any case, the having a dispenser return to the exact height for

each point of a dispensed pattern leads to a more reliable and consistent result.

To electronically determine the cant of a surface, first load a dispenser into the Microplotter

system. Next, calibrate the dispenser for sensing using the method described in the section

Dispenser measurement

.

Open the surface cant calibration window by selecting the toolbar item

Calibrate Surface

.

49

Summary of Contents for MICROPLOTTER II

Page 1: ...MICROPLOTTER II MANUAL REVISION 2 2 ...

Page 2: ...SONOPLOT INC 3030 LAURA LANE SUITE 120 MIDDLETON WI 53562 608 824 9311 CONTACT SONOPLOT COM 2 ...

Page 4: ...Dispenser refurbishing 59 Revision History 61 4 ...

Page 6: ......

Page 10: ......

Page 21: ...Fully installed Microplotter II system 19 ...

Page 22: ......

Page 58: ......

Page 62: ......

Page 64: ......

Page 66: ...60 ...