21

Instruction for use | Supercal 5

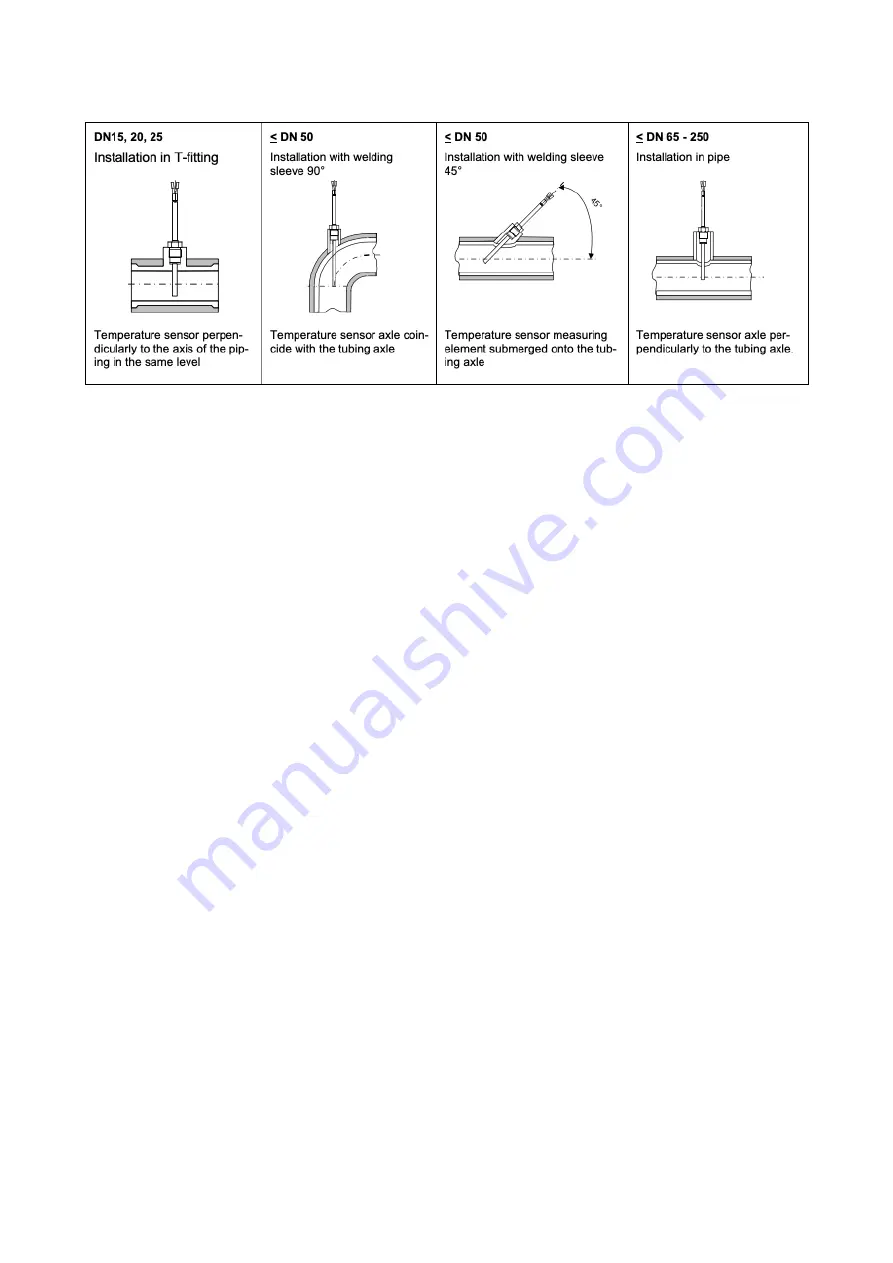

4.7.3 Installation Guidelines for Temperature Sensors According to EN1434

4.7.3.1 Compliance With the Operating Conditions According to MID

for the Temperature Sensors

The temperature sensors must be installed symmetrically in the flow and return pipes pref

-

erably directly. If temperature sensors are installed with pockets, both must be tested for

conformity. The tips of the temperature sensors should sit cleanly on the thermowell bot-

toms. Installation points in the flow sensor can be used if the temperature sensors are in

-

stalled symmetrically.

If the temperature sensors are permanently connected, the connecting cables must not be

shortened.

Interchangeable temperature sensors with conformity markings allow a maximum length of

15 m with equal length for flow and return.

EN 1434-2 applies to the cable cross-sections. Care must be also be taken to ensure that the

calculator is electrically compatible with the temperature sensors:

The calculator has been designed for Pt500 temperature sensors. Don't use other

sensors.

To prevent unauthorized access, the installation points must be sealed last.

4.8 Installation Check

For the installation of the heat meter and the associated temperature sensors, the general

installation regulations according to EN 1434 Part 6 and the PTB Technical Guideline TR-K 9

must be adhered to. Guideline TR-K 9 is available for download on the PTB website.

After the shut-off valves have been opened, the installation must be checked for leaks. By

repeatedly pressing the orange operating button, various operating parameters can be read

on the LCD display of the calculator, e. g. flow rate, power, and flow and return temperature.

The communication indicator on the LCD display can be used to check the communication

input or output. The Superprog software can also be used to simulate communication out-

puts. The flow rate can be checked using the flow rate indicator. The dynamics of the flow

sensor can be checked using the current flow display in conjunction with flow control.

All parameter displays are used to check the meter or to adjust the system. Check that the

adjusted flow rate of the system does not exceed the maximum permitted flow rate of the

meter. It is recommended that an installation protocol is made using the Android NFC tool or

the optical interface with the Superprog software for complete functional testing.

Summary of Contents for Supercal 5 I

Page 1: ...Instructions for Use Supercal 5 I...

Page 6: ...6 Instruction for use Supercal 5...

Page 55: ...55 Instruction for use Supercal 5 The interfaces of the NOWA adapter...

Page 66: ......

Page 67: ......