1-23

DNW-75/75P

DNW-65/65P

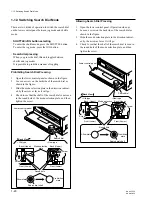

1-14-3. System Phase Alignment

An external reference video signal and analog composite signal must be input to this unit after they are

adjusted so that SC-H conforms to the specifications.

When Connecting to a Digital Switcher

Fundamentally, the system phase adjustment is not necessary.

Refer to the manual of digital switcher for details.

When Connecting to an Analog Switcher

Perform the system phase adjustment according to the manual of the analog switcher.

To adjust the system phase of this unit, use the SYNC and SC control knobs of SYSTEM PHASE on the

sub control panel.

m

.

When the DNW-75/75P, be sure to adjust in PB mode.

The system phase does not change even if the SYNC/SC control knob is turned in the REC mode, but it

changes when the REC mode is shifted to the PB mode.

.

The playback sound may be momentarily interrupted when the SYNC/SC control knob is turned during

tape playback.

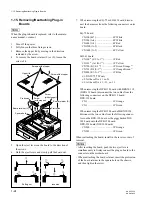

1-14-4. Setup Menu Settings

Video/Sync Delay Setting “ITEM-701” (DNW-75/75P only)

Commonly, when integrating the menu into the editing system, set on “VIDEO”.

To prevent the picture shift during EE/PB switching in the VTR-to-VTR edit operation, this setup menu is

also set to “VIDEO”.

Analog Component Signal Format Setting “ITEM-709” (525/60 system only)

The input (SUB-ITEM-0: DNW-75/75P only) and output (SUB-ITEM-1) sides are set to “D-1” or “B-

CAM” according to the operating system, respectively.

1-14. Settings and Adjustment when External Equipment is Connected