5-3

DNW-7/90/90WS

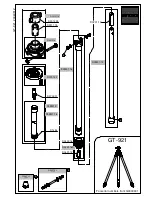

VA-191/167 Board (A side)

1

RV101

1

RV201

TP1

1

RV301

5-4. VA Gain Adjustment

Note

.

Use a reflective chart (Reflection rate : 89.9 %) in this

adjustment as possible. Adjust the color temperature to

3200 K exactly. If a pattern box is used, check it’s state

before use. Set the luminous intensity of the chart to

2000 lx.

Preparation

.

OUTPUT/DCC switch (inside panel)

→

CAM/ON

.

Shoot a gray-scale chart in the full underscan’s picture

frame.

.

WHITE BAL switch (inside panel)

→

PRST

.

AUTO W/B BAL switch (front panel)

→

BLK

(Perform the automatic black balance adjustment.)

Adjustment procedure

1.

Equipment

: Oscilloscope

Test point

: TP1/VA-191 (VA-167)

Setting point :

1

Lens IRIS

Spec.

: A = 280

±

8 mV

2.

On the setting menu, set as follows.

PAGE

: FUNCTION 1/2

ITEM

: TEST OUT

→

G

3.

Equipment

: Waveform monitor

Test point

: TEST OUT connector

(inside panel)

Adj. point

:

1

RV201/VA-191 (VA-167)

Spec.

: B = 100

±

2 IRE (NTSC)

B = 700

±

10 mV (PAL)

5-4. VA Gain Adjustment

C

D

A

B

4.

On the setting menu, set as follows.

PAGE

: FUNCTION 1/2

ITEM

: TEST OUT

→

ENC

ITEM

: GAMMA

→

OFF

5.

Select portion C by using the waveform monitor.

6.

Set the waveform monitor to the CHROMA mode.

7.

Equipment

: Waveform monitor

Test point

: TEST OUT connector

(inside panel)

Adj. point

:

1

RV101/VA-191 (VA-167)

1

RV301/VA-191 (VA-167)

Spec.

: Minimize carrier leak D by using the

variable resistors alternately.

Setting after adjustment

.

On the setting menu, set as follows.

PAGE

: FUNCTION 1/2

ITEM

: GAMMA

→

ON