3-33

BVW-55 P2

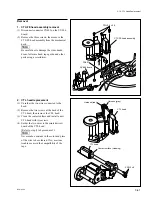

3. Pinch arm assembly installation

(1) Clean the pinch arm lifting shafts with

cleaning cloth moistened with cleaning fluid.

(2) Apply a quarter drop of oil to the pinch arm

lifting shafts.

(3) Put the holes of the pinch arm assembly into

the pinch arm lifting shafts while putting the

slider of the pinch arm assembly into the

notch of the pinch press cam.

(4) Install a new E ring to the pinch arm lifting

shaft.

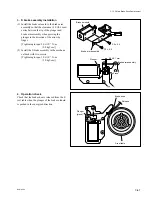

4. Cleaning

Clean the surface of the pinch roller and T3 tape

guide with cleaning cloth moistened with clean-

ing fluid. (Refer to the maintenance manual Part

1, Section 4-2-6.)

5. Operation check

Check that the pinch roller is engaged to the

capstan shaft when the unit is in the threading end

state.

Adjustment after replacement

6. Tape running adjustment

(Refer to Section 5-4.)

3-7. Pinch Roller Replacement

E ring

Pinch arm assembly

Pinch arm lifting shafts

Notch

Slider

Pinch press

cam

Summary of Contents for BVW-55

Page 4: ......

Page 8: ......

Page 50: ...1 40 BVW 55 1 2 3 4 5 6 7 8 9 d l s d l 1 15 Fixtures and Adjustment Equipment List ...

Page 58: ......

Page 106: ......

Page 116: ......

Page 130: ......

Page 148: ......

Page 154: ......

Page 158: ......

Page 169: ...1 9 BVW 55 P2 1 2 Fixtures and Adjustment Equipment List 1 2 3 4 5 6 7 8 9 d l s d l ...

Page 176: ......

Page 272: ......

Page 384: ......

Page 392: ......

Page 396: ...1 2 BVW 55 ...

Page 666: ......

Page 705: ......

Page 752: ......

Page 780: ......

Page 805: ......

Page 848: ......

Page 856: ......

Page 870: ......

Page 884: ......

Page 904: ......

Page 909: ...5 27 b BVW 55 5 27 b CN101 CN301 CN302 CN303 CN901 MB 838 B SIDE SUFFIX 12 MB 838 MB 838 ...

Page 911: ...5 27 a BVW 55 5 27 a CN101 CN301 CN302 CN303 CN901 MB 838 B SIDE SUFFIX 11 MB 838 MB 838 ...

Page 940: ......