3-53

BVW-55 P2

3-14. S Reel Motor Replacement

Outline

Replacement

S reel motor removal

S reel motor installation

Adjustment after replacement

S REEL FG DUTY adjustment

Tape running adjustment

Precaution

Remove the mechanical deck assembly from the unit when the S reel motor is rep

laced. Be careful not to damage the video heads, drum, and other parts during

removal.

Preparations

1.

Turn off the power.

2.

Remove the mechanical deck. (Refer to Section 3-1-8.)

Tools

.

Hexagon bit (Across flat has 1.5 mm):

J-6326-120-A

.

Torque screwdriver bit (for M1.4):

J-6325-110-A

.

Torque screwdriver bit (for M2):

J-6325-380-A

.

Torque screwdriver (for 3 kg):

J-6325-400-A

3-14. S Reel Motor Replacement

Removal

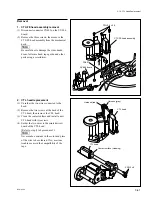

1. S reel motor removal

(1) Remove the three screws, then remove the S

reel motor.

(2) Disconnect the harness from the board of the

S reel motor. Be careful not to lose the

harness because it is used again.

PSW2

x

5

Positioning hole

Positioning pin

Harness

S reel motor

Summary of Contents for BVW-55

Page 4: ......

Page 8: ......

Page 50: ...1 40 BVW 55 1 2 3 4 5 6 7 8 9 d l s d l 1 15 Fixtures and Adjustment Equipment List ...

Page 58: ......

Page 106: ......

Page 116: ......

Page 130: ......

Page 148: ......

Page 154: ......

Page 158: ......

Page 169: ...1 9 BVW 55 P2 1 2 Fixtures and Adjustment Equipment List 1 2 3 4 5 6 7 8 9 d l s d l ...

Page 176: ......

Page 272: ......

Page 384: ......

Page 392: ......

Page 396: ...1 2 BVW 55 ...

Page 666: ......

Page 705: ......

Page 752: ......

Page 780: ......

Page 805: ......

Page 848: ......

Page 856: ......

Page 870: ......

Page 884: ......

Page 904: ......

Page 909: ...5 27 b BVW 55 5 27 b CN101 CN301 CN302 CN303 CN901 MB 838 B SIDE SUFFIX 12 MB 838 MB 838 ...

Page 911: ...5 27 a BVW 55 5 27 a CN101 CN301 CN302 CN303 CN901 MB 838 B SIDE SUFFIX 11 MB 838 MB 838 ...

Page 940: ......