3

D-F200/F201

L3

AM

FERRITE-

ROD

ANTENNA

L1

CD DOOR

OPEN

13

24

12

1

TP5

TP1

TP18

TP813

TP311

TP816

TP20

P75

D1

D2

C7

FB311 FB111

C10

16

R28

C2

C37

C41

C3

C46

C15

C254

C154

C319

R102

R202

R354

C350

C351

C30

C841

C300

R26

R6

R2

R9

R16

R3

C313

Q8

C13

R18

R254

R19

IC302

R841

R24

R154

Q7

R17

C359

R7

D3

C36

C34

R843

FR

MODEL

R317

C29

R27

C354

D304

C301

S810

L4

CF1

S801

S811

S801

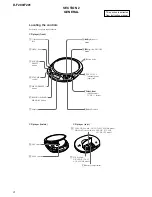

– MAIN BOARD (SIDE B) –

TP416

Q53

C43

R72

R70

L312

CT3

C9

C8

C39

C204

C104

C318

C361

C353

R8

C352

C201

R353

TAP802

C360

R25

R101

R316

R201

D301

TAP802

– MAIN BOARD (SIDE A) –

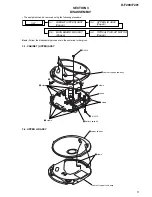

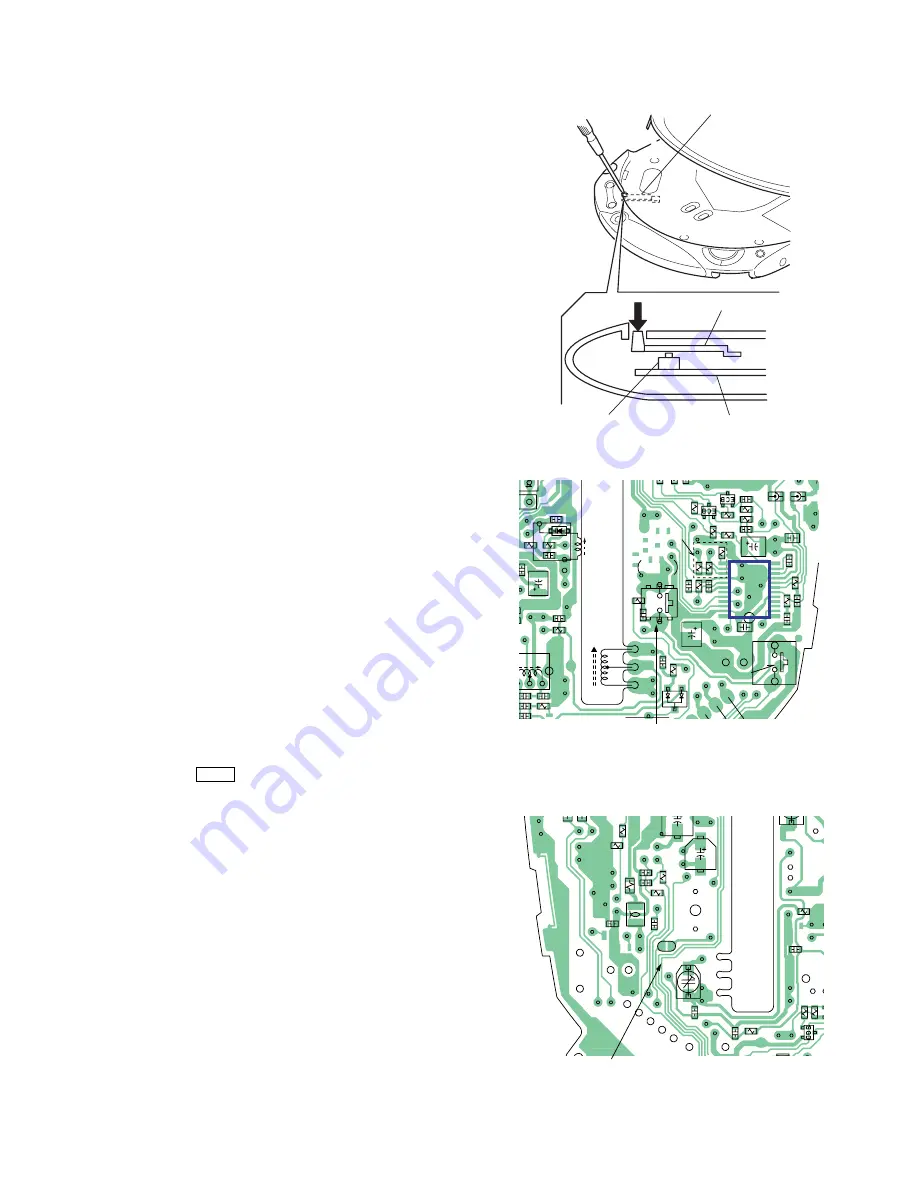

SECTION 1

SERVICE NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electro-

static breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

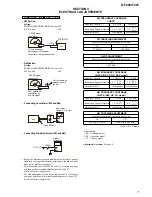

Precautions for Checking Emission of Laser Diode

Laser light of the equipment is focused by the object lens in the

optical pick-up so that the light focuses on the reflection surface

of the disc. Therefore, be sure to keep your eyes more then 30 cm

apart from the object lens when you check the emission of laser

diode.

Before Replacing the Optical Pick-Up Block

Please be sure to check throughly the parameters as par the “Opti-

cal Pick-Up Block Checking Procedures” (Part No.: 9-960-027-

11) issued separately before replacing the optical pick-up block.

Note and specifications required to check are given below.

• FOK output : IC601

yg

pin

When checking FOK, remove the lead wire to disc motor.

• RF signal P-to-P value : 0.45 ± 0.1 Vp-p

• The repairing grating holder is impossible.

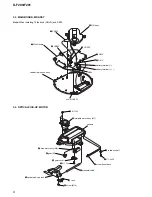

Laser Diode Checking Methods

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper lid is closed while turning ON

the S801. (push switch type)

The following two checking methods for the laser diode are

operable.

• Method:

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. With a disc not set, turn on the S801 with a screwdriver having a

thin tip as shown in Fig.1.

or TAP802 is shorted as shown in Fig.2.

Note: Do not push the detection lever strongly, or it may be bent

or damaged.

3. Press the

N

X

button.

4. Observing the objective lens, check that the laser diode emits

light.

When the laser diode does not emit light, automatic power

control circuit or optical pick-up is faulty.

In this operation, the objective lens will move up and down 5

times along with inward motion for the focus search.

Fig. 2

Fig. 1

detection lever

detection lever

main board

S801