2

CDX-5V661/5V661A/5V661D/5V661S

TABLE OF CONTENTS

1.

SERVICING NOTES

................................................

3

2.

DISASSEMBLY

2-1. Disassembly Flow ...........................................................

4

2-2. Cover (Up) .......................................................................

5

2-3. Front Panel Section .........................................................

5

2-4. Mechanism Deck (MG-160-154) ...................................

6

2-5. MAIN Board ...................................................................

7

2-6. Slide Variable Resistor

(Elevator Height Sensor) (RV1) .....................................

8

2-7. ASSIST Board .................................................................

8

2-8. L Motor Assy (Loading) (M103) ....................................

9

2-9. Chassis (TR) Main Assy .................................................

9

2-10. Bracket (DE) Main Assy ................................................. 10

2-11. Slider (TOP) Assy ........................................................... 10

2-12. Bracket (UD) Assy .......................................................... 11

2-13. Guide (Chuck) ................................................................. 11

2-14. Setting The OP Block Assy In The Highest Position ..... 12

2-15. Address Detection Flexible Board .................................. 13

2-16. Torsion Spring (OP) ........................................................ 13

2-17. OP Block Assy ................................................................ 14

3.

ELECTRICAL ADJUSTMENT

............................ 15

4.

DIAGRAMS

4-1. Block Diagram – MAIN Section – ................................. 39

4-2. Block Diagram – DISPLAY/POWER Section – ............ 40

4-3. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 41

4-4. Schematic Diagram – MAIN Board (1/3) – ................... 43

4-5. Schematic Diagram

– MAIN (2/3)/ASSIST/POS Boards – ........................... 44

4-6. Schematic Diagram – MAIN Board (3/3) – ................... 45

4-7. Printed Wiring Boards

– MAIN (Component Side)/ASSIST/POS Boards – ..... 46

4-8. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 47

4-9. Printed Wiring Board – KEY Board – ............................ 48

4-10. Schematic Diagram – KEY Board – .............................. 49

4-11. Printed Wiring Board – F2 Board – ................................ 50

4-12. Schematic Diagram – F2 Board – ................................... 51

4-13. Printed Wiring Board – F1 Board – ................................ 52

4-14. Schematic Diagram – F1 Board – ................................... 52

4-15. IC Pin Function Description ........................................... 57

5-1. Cover Section .................................................................. 60

5-2. Front Panel Section ......................................................... 61

5-3. Chassis Section ............................................................... 62

5-4. Mechanism Deck Section-1 (MG-160-154) ................... 63

5-5. Mechanism Deck Section-2 (MG-160-154) ................... 64

............................... 65

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK

0

OR DOTTED

LINE WITH MARK

0

ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUB-

LISHED BY SONY.

The laser diode in the optical pick-up block may suffer electro-

static break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emis-

sion, observe from more than 30 cm away from the objective lens.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

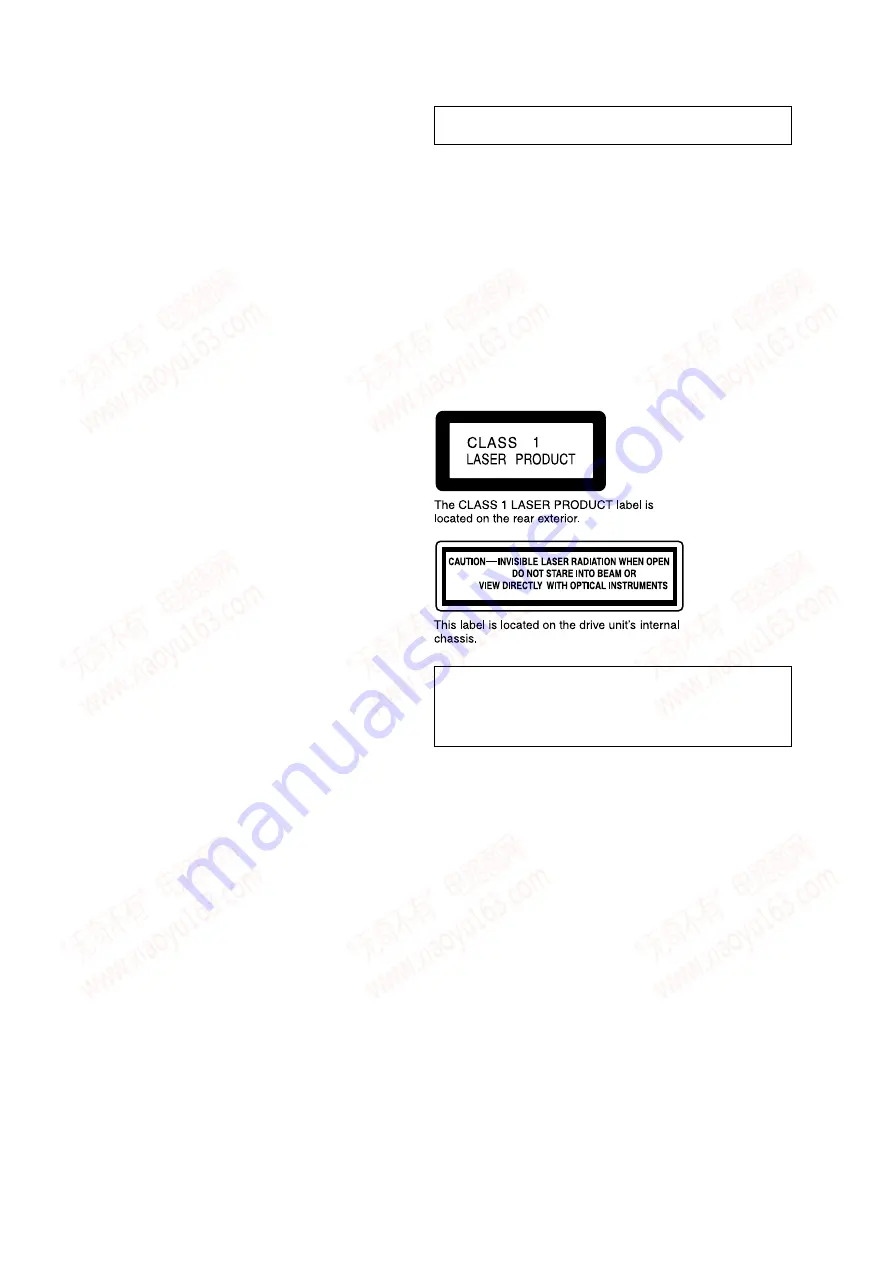

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous ra-

diation exposure.

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299