— 4 —

DSC-P9

TABLE OF CONTENTS

1.

SERVICE NOTE

························································ 1-1

Self-diagnosis Display ····················································· 1-3

2.

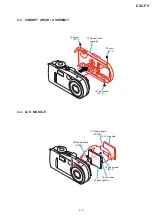

DISASSEMBLY

2-1.

BT Lid ············································································· 2-2

2-2.

Cabinet (Front) Assembly ··············································· 2-2

2-3.

Cabinet (Rear) Assembly ················································· 2-3

2-4.

LCD Module ···································································· 2-3

2-5.

Cabinet (Bottom) Assembly ············································ 2-4

2-6.

Lens Block Assembly ······················································ 2-4

Service Position (SY-77 Board: Side A) ·························· 2-5

2-7.

Control Switch Block ······················································ 2-5

2-8.

SY-77 Board ···································································· 2-6

2-9.

Memory Stick Connector ················································ 2-6

2-10. ST-70 Board ····································································· 2-7

2-11. SW-368 Board ································································· 2-7

2-12. JK-227 Board ·································································· 2-8

Service Position (SY-77 Board: Side B) ·························· 2-8

2-13. Circuit Boards Location ·················································· 2-9

3.

BLOCK DIAGRAMS

3-1.

Overall Block Diagram ··················································· 3-1

3-8.

Power Block Diagram 1 ················································ 3-15

3-9.

Power Block Diagram 2 ················································ 3-17

4.

PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1.

Frame Schematic Diagrams ············································· 4-1

Frame Schematic Diagram (1/2) ····································· 4-1

Frame Schematic Diagram (2/2) ····································· 4-3

4-2.

Schematic Diagrams ························································ 4-5

CD-397 (CCD IMAGER) ··············································· 4-7

SW-368 (1/2) (CONTROL SWITCH) ·························· 4-29

SW-368 (2/2)

(LCD DRIVE, TIMING GENERATOR) ····················· 4-31

ST-70 (FLASH DRIVE) ··············································· 4-35

4-3.

Printed Wiring Boards ··················································· 4-39

CD-397 ·········································································· 4-41

SW-368 ·········································································· 4-47

ST-70 ············································································· 4-51

4-4.

Waveforms ····································································· 4-54

4-5.

Parts Location ································································ 4-57

5.

ADJUSTMENTS

Before Starting Adjustment ······················································· 5-1

1-1.

Adjusting Items when Replacing

Main Parts and Boards ···················································· 5-2

5-1.

Camera Section Adjustments ··········································· 5-3

1-1.

Preparations Before Adjustment ······································ 5-3

1-1-1. List of Service Tools ························································ 5-3

1-1-2. Preparations ····································································· 5-4

1-1-3. Discharging of the Flashlight Power Supply ··················· 5-4

1-1-4. Precautions ······································································ 5-6

1.

Setting the Switch ···························································· 5-6

2.

Order of Adjustments ······················································ 5-6

3.

Subjects ··········································································· 5-6

4.

Preparing the Flash Adjustment Box ······························· 5-7

1-2.

Initialization of A, B, D, E, F, 7, 9 Page Data ················· 5-8

1-2-1. Initialization of A, D Page Data ······································ 5-8

1.

Initializing A, D Page Data ·············································· 5-8

2.

Modification of A, D Page Data ······································ 5-8

3.

A Page Table ···································································· 5-8

4.

D Page Table ···································································· 5-8

Section

Title

Page

Section

Title

Page

1-2-2. Initialization of B, E, F, 7, 9 Page Data ··························· 5-9

1.

Initializing B, E, F, 7, 9 Page Data ·································· 5-9

2.

Modification of B, E, F, 7, 9 Page Data. ·························· 5-9

3.

B Page Table ···································································· 5-9

4.

E Page Table ···································································· 5-9

5.

F Page Table ·································································· 5-10

6.

7 Page Table ··································································· 5-12

7.

9 Page Table ··································································· 5-12

1-3.

Video System Adjustments ············································ 5-13

1.

Video Sync Level Adjustment ······································· 5-13

2.

Video Burst Level Check ··············································· 5-13

1-4.

Camera System Adjustments ········································· 5-14

Data Setting During Camera System Adjustments ········ 5-14

Picture Frame Setting ···················································· 5-15

Check on the Oscilloscope ············································ 5-15

1.

Flange Back Adjustment

(Using the minipattern box) ·········································· 5-16

2.

Flange Back Adjustment

(Using the flange back adjustment chart) ······················ 5-17

3.

Flange Back Check ························································ 5-17

4.

F No. Compensation ······················································ 5-18

5.

Mechanical Shutter Adjustment ···································· 5-18

6.

Light Value Adjustment ················································· 5-19

7.

Mixed Color Cancel Adjustment ··································· 5-19

8.

Auto White Balance 3200K Standard Data Input 1 ······ 5-20

9.

Auto White Balance 3200K Standard Data Input 2 ······ 5-21

10.

Auto White Balance 3200K Standard Data Input 3 ······ 5-21

11.

Auto White Balance 3200K Check ······························· 5-22

12.

Auto White Balance 5800K Standard Data Input 1 ······ 5-23

13.

Auto White Balance 5800K Standard Data Input 2 ······ 5-24

14.

Auto White Balance 5800K Standard Data Input 3 ······ 5-24

15.

Auto White Balance 5800K Check ······························· 5-25

16.

CCD Linearity Check ···················································· 5-26

17.

Color Reproduction Adjustment ···································· 5-27

18.

CCD White Defect Compensation ································ 5-28

19.

CCD Black Defect Compensation ································· 5-29

20.

Strobe White Balance Adjustment ································· 5-30

21.

AF Illumination Check ·················································· 5-32

1-5.

LCD System Adjustments ············································· 5-33

1.

LCD Initial Data Input ·················································· 5-34

2.

VCO Adjustment (SW-368 Board) ································ 5-34

3.

Black Limit Adjustment (SW-368 Board) ····················· 5-35

4.

Bright Adjustment (SW-368 Board) ······························ 5-35

5.

Contrast Adjustment (SW-368 Board) ·························· 5-36

6.

VG Center Adjustment (SW-368 Board) ······················· 5-36

7.

PSIG Gray Adjustment (SW-368 Board) ······················ 5-37

8.

V-COM Adjustment (SW-368 Board) ··························· 5-37

9.

White Balance Adjustment (SW-368 Board) ················ 5-38

5-2.

Service Mode ································································· 5-39

2-1.

Adjusting Remote Commander ····································· 5-39

1.

Used the Adjusting Remote Commander ······················ 5-39

2.

Precautions upon Using the Adjusting

Remote Commander ······················································ 5-39

2-2.

Data Process ·································································· 5-40

2-3.

Service Mode ································································· 5-41

1.

Setting the Test Mode ···················································· 5-41

2.

Bit Value Discrimination ··············································· 5-41

3.

Mode Dial Check (1) ····················································· 5-41

4.

Mode Dial Check (2) ····················································· 5-41

5.

Switch Check (1) ··························································· 5-41

6.

Switch Check (2) ··························································· 5-42

7.

LED Check ···································································· 5-42

8.

Self Diagnosis Code ······················································ 5-42