CPD-G500

SECTION 4

ADJUSTMENTS

•

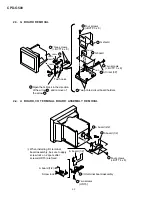

Landing Rough Adjustment

1. Enter the full white signal. (or the full black dots signal).

2. Adjust the contrast to the maximum.

3. Make the screen monogreen.

Note: Off the outputs from R ch and B ch of SG.

4. Reverse the DY, and adjust coarsely the purity magnet so

that a green raster positions in the center of screen.

5. Adjust the tilt of DY, and fix lightly with a clamp.

Note: “TILT” = “128”.

•

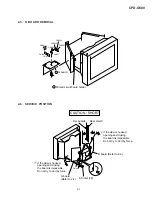

Landing Fine Adjustment

1. Put the set inside the Helmholtz coil. (“LCC SW” = “12”)

2. Input the single green signal and set the “CONTRAST”=

“255”.

Note: After the W/B adjustment with 9300K, measure an aver-

age of

Σ

Ik when a full white signal is entered in the CONT

MAX/BRT CENT status. Then make adjustment so that

the specified screen can be attained after aging for 2 hours

with Ik equivalent to 30% of the average value.

3. Demagnetize the metal part of the chassis with the hand de-

gausser and coil degausser, and the CRT surface with the

hand degausser.

Input AC 230V to AC IN, turn on and off the power to per-

form auto degaussing. (Perform auto degaussing by setting

“FUNCTION SW”=1. Return to the original value after

use.)

Demagnetize the CRT surface with the hand degausser

again.

Note:

(1) Hand degauss must be used on stand-by or power-off condi-

tion.

This model has an automatic earth magnetism correction

function by using an earth magnetism sensor and a LCC coil.

When using a hand degauss while monitor (LCC coil) is be-

ing operated, it sometimes gets magnetized, and the system

may not work properly as a result.

(2) Adjust in a non-magnetic field.

(3) If adjusting in a magnetic fields, add the shift from the non-

magnetic field in your estimation.

4. Attach the wobbling coil to the designated part of the CRT

neck.

5. Attach the sensor of the landing adjustment unit on the CRT

surface.

± 6

± 6

± 6

± 6

± 6

± 6

± 6

± 6

± 6

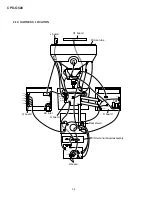

<Specifications>

Adjust so that the green is within

the specification given right.

4 corner adjust target : within ± 1

The red and blue must be within

the specification given right with

respect to the green.

A difference between red and blue

must be within the specification

given right.

0 ± 3 0 ± 7.5 0 ± 3

0 ± 3 0 ± 7.5 0 ± 3

0 ± 3 0 ± 7.5 0 ± 3

(µm)

(µm)

10

10

10

10

7

10

10

10

10

(µm)

* Adjustment and measurement should be made at the points

one inch inside the fluorescent screen.

7. For the up/down swing, swing the DY and insert a wedge so

that the up and down pins are equal at the top and bottom.

Adjust the H.TRP VR of DY so that the horizontal trapezoid

is equal at the left and right. Insert the wedge firmly so that

the DY does not shake.

8. Check the landing of each corner, and if it does not satisfy

the specification, adjust the landing of four corners using

“LCC LT“, “LCC LB”, “LCC RT” and “LCC RB”.

However, the register adjustment must be limited within the

following range.

“LCC NS”

128 ± 15

“LCC LT”, “LCC LB”, “LCC RT”, “LCC RB”

128 ± 40

After adjustment, save the service data.

9. Remove the sensor and wobbling coil.

10. Switch the signal to R.G.B., and check that each color is

pure.

11. Check that the DY is not tilting, and fix the purity Mg with a

white pen. Fix wedges with RTV.

4-1

6. Adjust the DY position and purity, and the DY tilt, and land-

ing of the center and 4 corners with the landing checker.

After adjustment, set “LCC SW” to “13”.

•

Write terrestrial magnetism sensor reading VX and VY to

“LCC VX” and LCC VY” respectively. Adjust the land-

ing by moving “LCC NS”, “LCC LT”, “LCC LB”, “LCC

RT” and “LCC RB”. However, the register adjustment

must be limited within the following range.

“LCC NS”

128 ± 15

“LCC LT”, “LCC LB”, “LCC RT”, “LCC RB”

128 ± 40

Save the service data.

Note: Hand degauss must be used on stand-by or power-off condition.

This model has an automatic earth magnetism correction function by using an earth magnetism sensor

and a LCC coil. When using a hand degauss while monitor (LCC coil) is being operated, it sometimes

gets magnetized, and the system may not work properly as a result.

Summary of Contents for FD Trinitron CPD-G500

Page 24: ...CPD G500 4 3 MEMO ...

Page 46: ...CPD G500 MEMO 6 4 ...