SAFETY CHECK-OUT

After correcting the original service problem,

perform the following safety checks before releasing

the set to the customer:

1.

Check the area of your repair for unsoldered or

poorly-soldered connections. Check the entire

board surface for solder splashes and bridges.

2.

Check the interboard wiring to ensure that no

wires are “pinched” or contact high-wattage

resistors.

3. Check that all control knobs, shields, covers,

ground straps, and mounting hardware have

been replaced. Be absolutely certain that

have replaced all the insulators.

4.

Look for unauthorized replacement parts, par-

ticularly transistors, that were installed during a

previous repair. Point them out to the customer

and recommend their replacement.

5.

Look for parts which, though functioning, show

obvious signs of deterioration. Point them out

to the customer and recommend their replace-

ment.

6.

Check the line cord for cracks and abrasion.

Recommend. the replacement of any such line

cord to the customer.

1.

Check the condition of the

antenna

(if any).

Make sure the end is not broken off, and has

the plastic cap

on

it. Point out the danger of

impalement on a broken antenna to the

customer,

and recommend the antenna’s

replacement.

8.

Check the Bt and HV to see they are at the

values specified. Make sure your instruments

are accurate; be suspicious of your HV meter

if sets always have low HV.

9. Check the antenna terminals, metal trim,

“metallized”

knobs, screws, and all other

exposed metal parts for AC leakage.

Check

leakage as described below.

To Exposed Metal

Parts on Set

A C

10.75

- E a r t h G r o u n d

A.

Using an AC voltmeter to check AC leakage.

LEAKAGE TEST

The AC leakage from any exposed metal part to

earth ground and from all exposed metal parts to any

exposed metal part having a return to chassis, must

not exceed 0.5

(500

Leakage

current can be measured by any one of three

methods.

1.

A commercial leakage tester, such as the

Simpson 229 or RCA

Follow the

manufacturers’ instructions to use these instru-

ments.

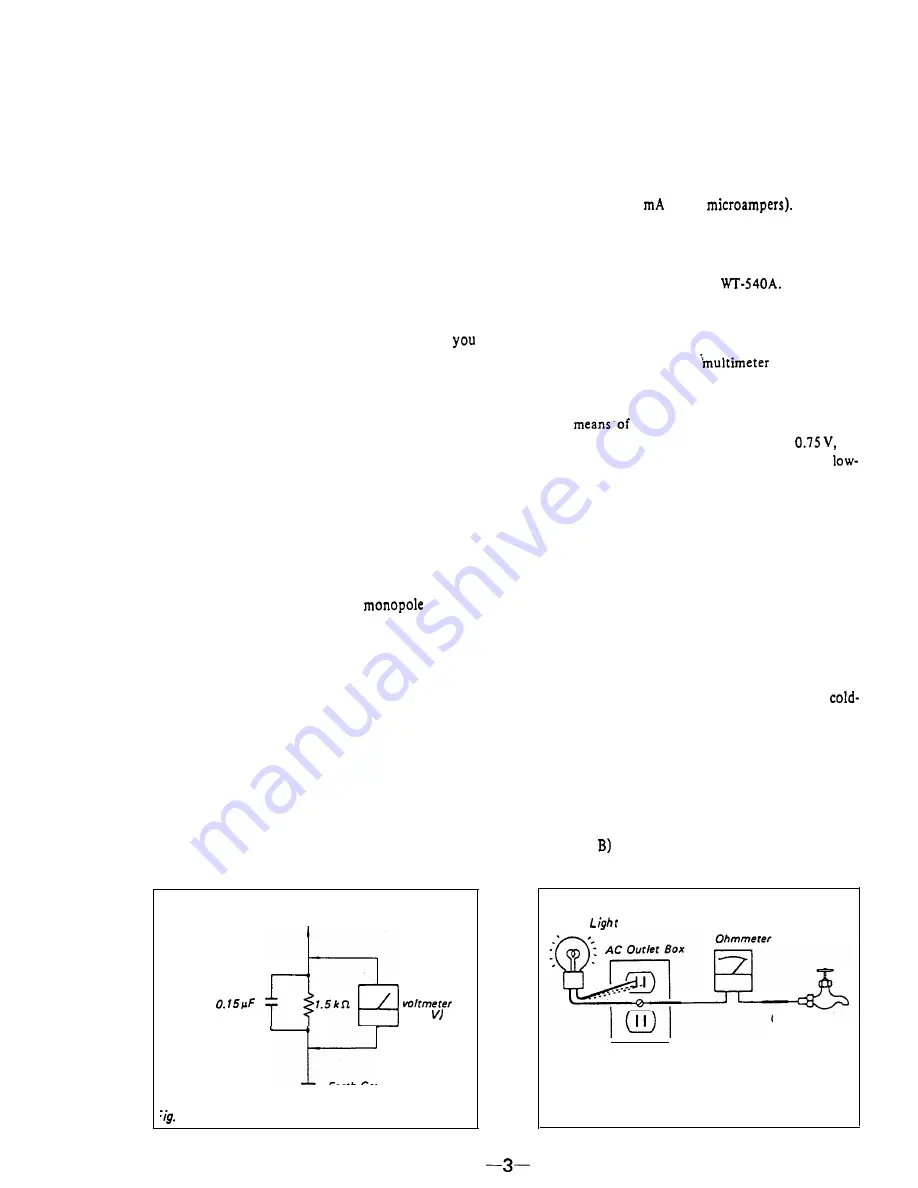

2.

A battery-operated AC milliammeter. The Data

Precision 245 digital

is suitable for

this job.

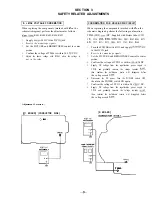

3.

Measuring the voltage drop across a resistor by

a VOM or battery-operated AC volt-

meter.

The “limit” indication is

so

analog meters must have an accurate

voltage scale. The Simpson 250 and Sanwa

SH-63Trd are examples of a passive VOM that

is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are

suitable. (See Fig. A)

HOW TO FIND A GOOD EARTH GROUND

A cold-water pipe is guaranteed earth ground; the

cover-plate retaining screw on most AC outlet boxes is

also at earth ground. If the retaining screw is to be

used as your earth-ground, verify that it is at ground

by measuring the resistance between it and a

water pipe with an ohmmeter. The reading should be

zero ohms.

If a cold-water pipe is not accessible,

connect a 60-100 watts trouble light (not a neon

lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate

the hot side of the line, the lamp should light at

normal brilliance if the screw is at ground potential.

(See Fig.

Trouble

Cold-warer Pipe

Fig. B.

Checking for earth ground.