6-35

6-2. MECHANISM SECTION

ADJUSTMENTS

Refer to the separate “8 mm Video Mechanism Section Adjustment

Manual

B Mechanism ” for adjustment, check procedure and

mechanical parts replacement.

2-1.

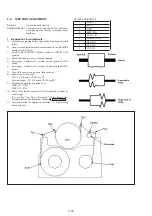

HOW TO OPERATE THE MECHANISM

AFTER THE CASSETTE COMPARTMENT IS

REMOVED

1. How to load a cassette tape:

1)

Refer to “1. Disassembly” and turn the main power on with

the cabinet and camera section removed. (It enables to operate

the mechanical deck.)

2)

Connect the adjustment remote commander and set the NORM

-ADJUST (HOLD) switch to ADJUST (ON) position.

3)

Check that the main power is being supplied.

4)

Select page : 6, address: 00, set data : 01 and press the PAUSE

button.

5)

Select page : F, address: 02, set data : 01 and press the PAUSE

button.

6)

Turn off the power supply once, then turn it on.

7)

Set the NORM-ADJUST (HOLD) switch to NORM (OFF)

position. (The adjustment remote commander can be

disconnected hereafter.)

8)

Press the push-switch-1 knob in the direction of arrow which

sets the machine into loading mode.

PB, FF/REW and CUE/REV operations are possible.

9)

After completing all steps of above operation, be sure to perform

“4. Processing after operation”.

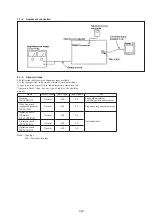

2. How to establish RECORD mode:

1)

Press pin of the push-switch 2 (ON state) and keep the ON

state by fixing with adhesive tape.

2)

Turn the main power switch ON (select VTR or CAMERA

position of camera).

3)

Set the RECORD switch to ON.

(When the test mode is selected, the rotation detection of the S

and T reel tables is muted, and the top end sensor is disable

which allow to run the tape.)

3. How to eject a cassette tape:

1)

Press the EJECT switch to ON.

4. Processing after operation

1)

Connect the adjustment remote commander and set the NORM

- ADJUST (HOLD) switch to ADJUST (ON) position.

2)

Select page 6, address : 00, set data : 01 and press the PAUSE

button.

3)

Select page: F, address : 02, set data : 00 and press the PAUSE

button.

4)

Remove the power supply to the machine.

Summary of Contents for Handycam CCD-TR501E

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 30: ...2 6 2 11 INTERNAL VIEWS LEFT SIDE RIGHT SIDE ...

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 127: ......

Page 166: ......

Page 168: ......

Page 169: ......

Page 170: ......

Page 171: ......

Page 172: ......

Page 173: ......

Page 174: ......

Page 175: ......

Page 176: ......

Page 177: ......

Page 178: ......

Page 179: ......

Page 180: ......

Page 181: ......

Page 182: ......

Page 183: ......

Page 184: ......

Page 185: ......

Page 186: ......

Page 187: ......

Page 188: ......

Page 189: ......

Page 190: ......

Page 191: ......

Page 192: ......

Page 193: ......

Page 194: ......

Page 195: ......

Page 196: ......

Page 197: ......

Page 198: ......

Page 199: ......

Page 200: ......

Page 201: ......

Page 202: ......

Page 203: ......