– 16 –

SECTION 5

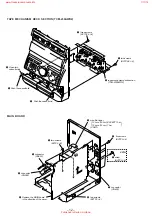

MECHANICAL ADJUSTMENTS

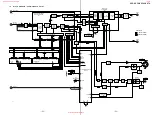

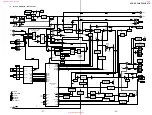

SECTION 6

ELECTRICAL ADJUSTMENTS

1. Demagnetize the record/playback head with a head demagne-

tizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit ad-

justment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and R-

CH.

7. Switches and controls should be set as follows unless other-

wise specified.

8. Set to the DOLBY NR OFF.

9. Set to the test mode.

(1) Press the

1

/

u

button to turn the power ON.

(2) Select the function “TAPE A or B”.

(3) Press the button of

p

,

[ENTER/NEXT]

, and

[DISC 3]

simultaneously, to set the tape deck test mode and blink

the indicator of disc tray number on the fluorescent indi-

cator tube.

(4) To exit from the test mode, press the

1

/

u

button.

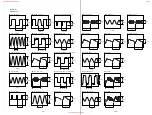

• Test Tape

Record/Playback Head Azimuth Adjustment

Note:

Perform this adjustments for both decks

Procedure:

1. Mode: Playback (FWD)

Tape

Signal

Used for

P-4-A100

10 kHz, – 10 dB

Azimuth Adjustment

WS-48B

3 kHz, 0 dB

Tape Speed Adjustment

P-4-L300

315 Hz, 0 dB

Level Adjustment

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

2 to 6 g • cm

(0.03 – 0.08 oz • inch)

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

2 to 6 g • cm

(0.03 – 0.08 oz • inch)

71 to 143 g • cm

(0.99 – 1.99 oz • inch)

100 g or more

(3.53 oz or more)

100 g or more

(3.53 oz or more)

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads

pinch rollers

erase head

rubber belts

capstan

idlers

2. Demagnetize the record/playback head with a head demagne-

tizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power sup-

ply voltage unless otherwise noted.

Torque Measurement

Mode

FWD

Torque meter

CQ-102C

Meter reading

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

0 dB = 0.775 V

DECK SECTION

DECK A DECK B

set

MAIN board

MD OUT jack (J101)

L-CH, R-CH

+

–

level meter

test tape

P-4-A100

(10 kHz, – 10 dB)

www.freeservicemanuals.info

1/11/16

Published in Heiloo, Holland.