40

English

Operation

Note

•

The display example shows the case where the resolution is set to 0.0005 mm.

•

The same applies in the case of RS232C commands.

Also, when an operation is performed using RS232C commands, there is a command that

performs absolute zero point processing directly without setting the absolute zero point mode.

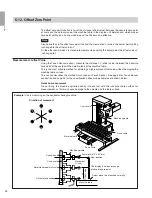

Setting of datum point

Operating Procedure

Select the X-axis.

“0” input can be omitted.

Press the datum point setting key.

Check that the REF lamp is on. When it is

not lighted, press the

F

key three times to

turn on the absolute zero point LED.

Select the X-axis again.

The mark “

” ligths.

Press the HOLD key. (It is ready for holding

the displayed value of the distance L between

the machining datum point and the absolute

zero point of scale.)

Absolute zeropoint mode LED and arrow

indicator flash.

When the scale absolute zero point is passed,

the buzzer sounds, the mark “

” and the

arrow indicator light, and the display value is

held. The absolute zero point mode LED lights.

Select the X-axis.

Press the HOLD key to release the HOLD

mode. The spot position is displayed and the

marks

“

/

” and “

” go out.

Here, the hold value is stored internally.

Note

When this processing is performed with an

RS232C command, “H” is replaced by “S”.

Display

X

0

S

F

F

F

X

H

START

mm

mm

mm

mm

INC

INC

ABS

mm

ABS

ABS

mm

ABS

REF

REF

REF

Spot position

Absolute zero

point of scale

X

H

START

L

Absolute zero

point of scale

Machining datum

point

Flashes

Lights up

Across

absolute

zero point

Lights up

ABS

mm

REF

REF

ABS

mm

Lights up

(Example)

Lights up

Lights up

Flashes

ABS

mm

REF

Buzzer

Lights up

Lights up