44

English

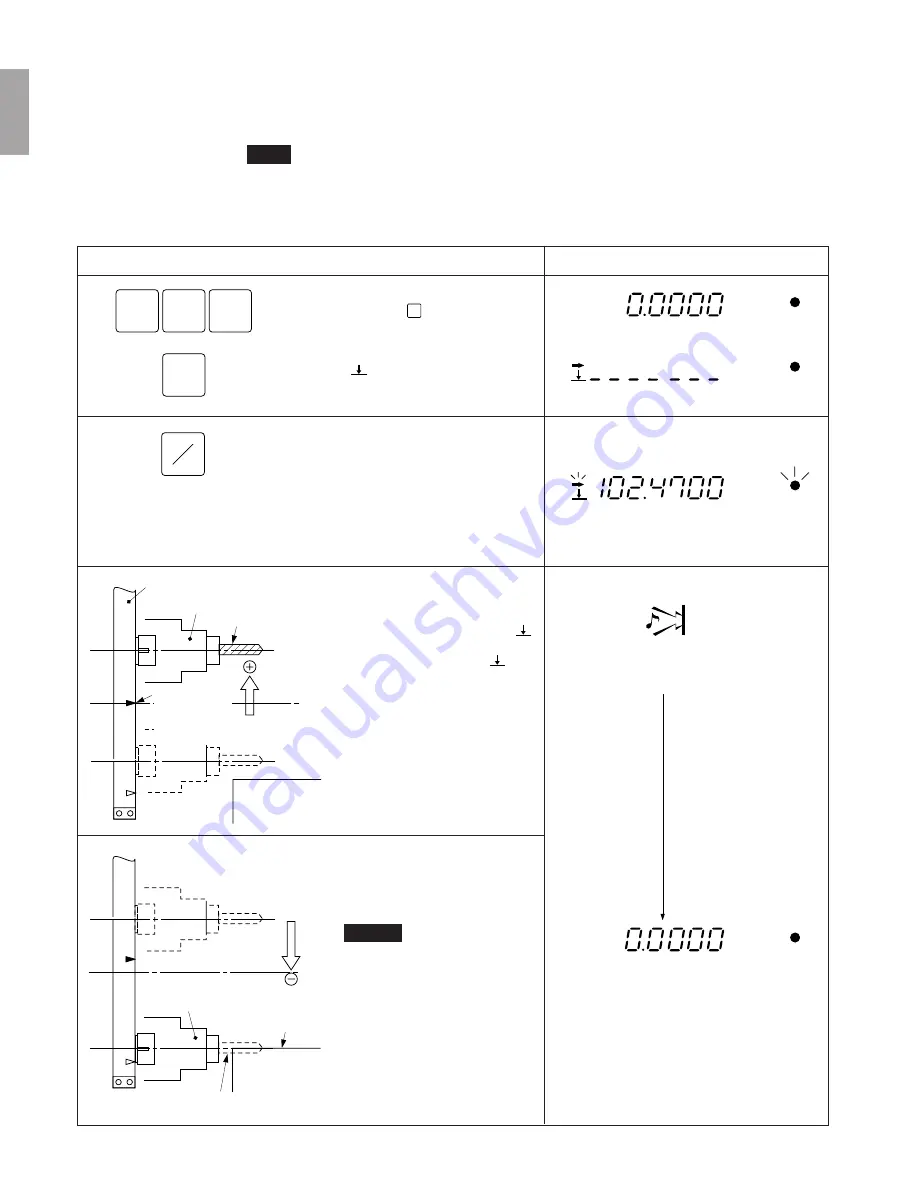

5-12-2. Operation of offset zero point

Note

In the example shown below, the resolution is set to 0.0005 mm.

The following is an example of Y-axis operation. For X-, Z-axis, perform the same key operation

for each axis.

Operating Procedure

Check that the REF lamp is on. When it is

not lighted, press the

F

key three times to

select the absolute zero point mode.

Select the Y-axis.

The mark “

” lights up.

Press the LOAD key.

The offset value

∆

Y in the display unit is

displayed.

The offset value

∆

Y stored in the display unit is

displayed.

The arrow indicator and Absolute zero point

mode LED.

Y

F

F

F

L

SET

Do not hit the table with the tool.

Machine table

Machine spindle

Along Y-axis

Machine zero point

Display

mm

INC

mm

INC

REF

REF

Cutting tool

Along Y-axis

Machine spindle

Scale

Absolute zero

point of scale

Spot position

Machine table

Accross absolute zero point

When the machine spindle is moved

in the + direction along the Y-axis, and

the absolute zero point of the scale is

passed, the buzzer sounds, the “

”

count is started, and the spot position

is displayed. The mark “

” and

arrow indicator go out. The absolute

zero point mode LED lights.

Next, move the machine spindle

toward the (–) side along the Y-axis.

Theposition where the displayed

value is “0” is the machine zero point.

Caution

Be carefull not to hit the machine

table with the tool when moving the

machine spindle inthe (–) direction.

ABS

mm

REF

Counting starts

Buzzer

Lights up

Lights up

Lights up

ABS

mm

REF

Flashes

Flashes