25

English

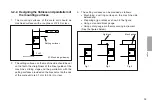

3-2-2. Designing the flatness and parallelism of

the mounting surfaces

1.

The mounting surfaces of the scale unit should be

machined surfaces with a roughness of 25 S or less.

2.

The setting surfaces on the machine side should be set

so that both the straightness of the linear guides of the

machine’s sliding stage and the parallelism with the

setting surfaces provided on the brackets at both ends

of the scale unit are 0.1 mm (0.004 in) or less.

3.

The setting surfaces can be provided as follows.

•

Machining a setting surface on the machine side

beforehand

•

Preparing a jig or block as shown in the figure

•

Using a standard block gauge

•

Using a dial gauge or other measuring instrument

(See the figures below.)

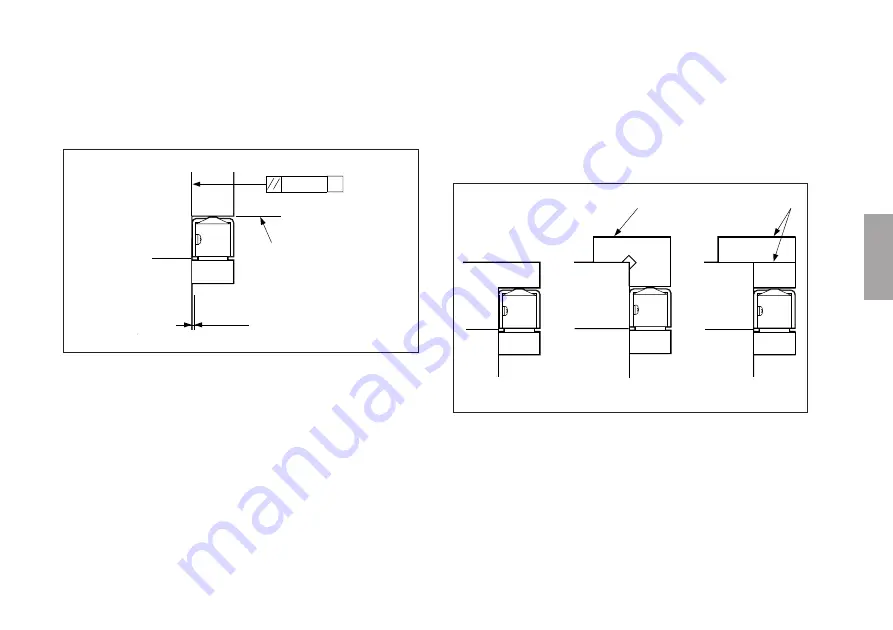

0.05

M

0±0.1

Block gauge

Jig block

Fig.1

Fig.2

Fig.3

Setting surfaces

M : Machine guideway