28

English

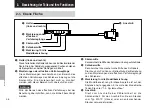

1.

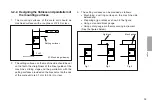

Check the mounting surfaces of the scale unit and

slider.

• Check that the mounting surfaces are machined

surfaces with a roughness of 25 S or more.

• The mounting surfaces of the scale unit and slider

should be planar (maximum difference 0.1 mm

[0.004 in]).

• When providing the setting surfaces on the machine,

check that the parallelism between the machine

guide M and the setting surfaces is 0.1 mm (0.004

in)/M or less. Also check that the gap between the

scale unit and slider setting surfaces is 12.7 ±0.1 mm

(0.5 ±0.004 in).

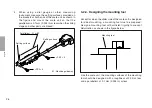

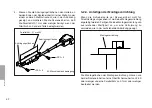

3.

Lock the scale unit.

• When setting surfaces are provided, press the scale

unit against the setting surfaces of the machine and

then tighten the screws with a tightening torque of

0.15 N•m (1.5 kgf•cm).

• If there are no setting surfaces, position the setting

surfaces on both ends of the scale unit so that they

are parallel to within 0.1 mm using a dial gauge and

then tighten the screws in the same manner.

Check that the gap between the surfaces is 12.7 ±0.1

mm (0.5 ±0.004 in).

4.

Lock the slider

• When setting surfaces are provided, press the slider

against the setting surfaces of the machine and then

tighten the screws with a tightening torque of 0.15

N•m (1.5 kgf•cm).

• If there are no setting surfaces, set the slider in the

slider holder, press it against the scale unit, and then

tighten the screws in the same manner.

5.

Remove the slider holder

• Remove the three M1.4 screws securing the slider

holder and remove the slider holder.

• Save the removed slider holder and screws for future

use.

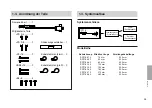

6.

Affix the blindfold label

• Affix the blindfold label so that it covers the two M1.4

screw holes.

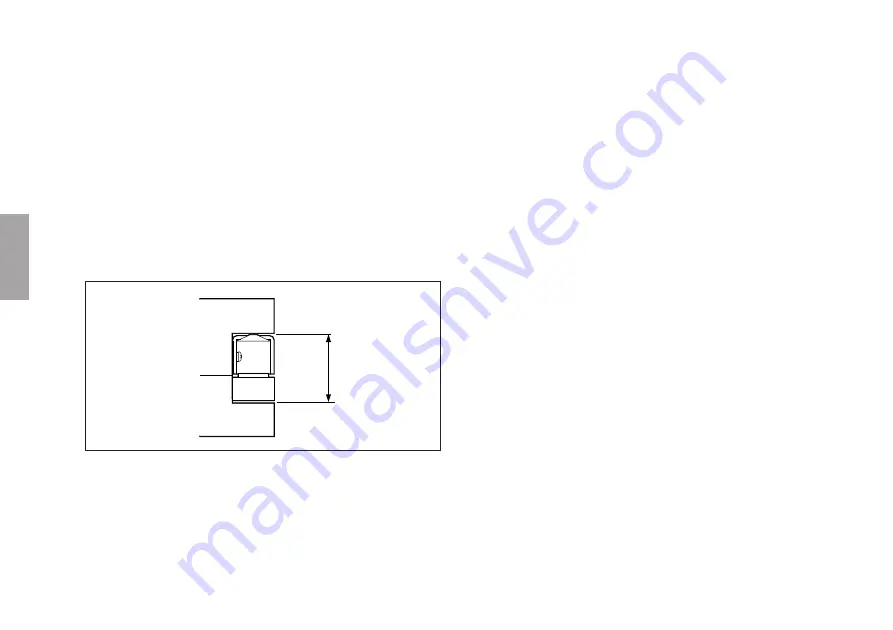

12.7±0.1

(0.5 ±0.004 in)

2.

Provisionally secure the scale unit and slider.

• Move the operating parts of the machine so that the

mounting surface of the slider comes roughly below

the center of the stroke. Then provisionally secure

the scale unit using the suPS2

×

4 screws

and the slider using the +PS2

×

8 screws.

• Next, loosen the three mounting screws attached to

the scale unit.