17

4

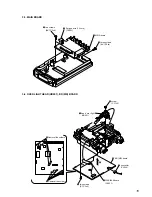

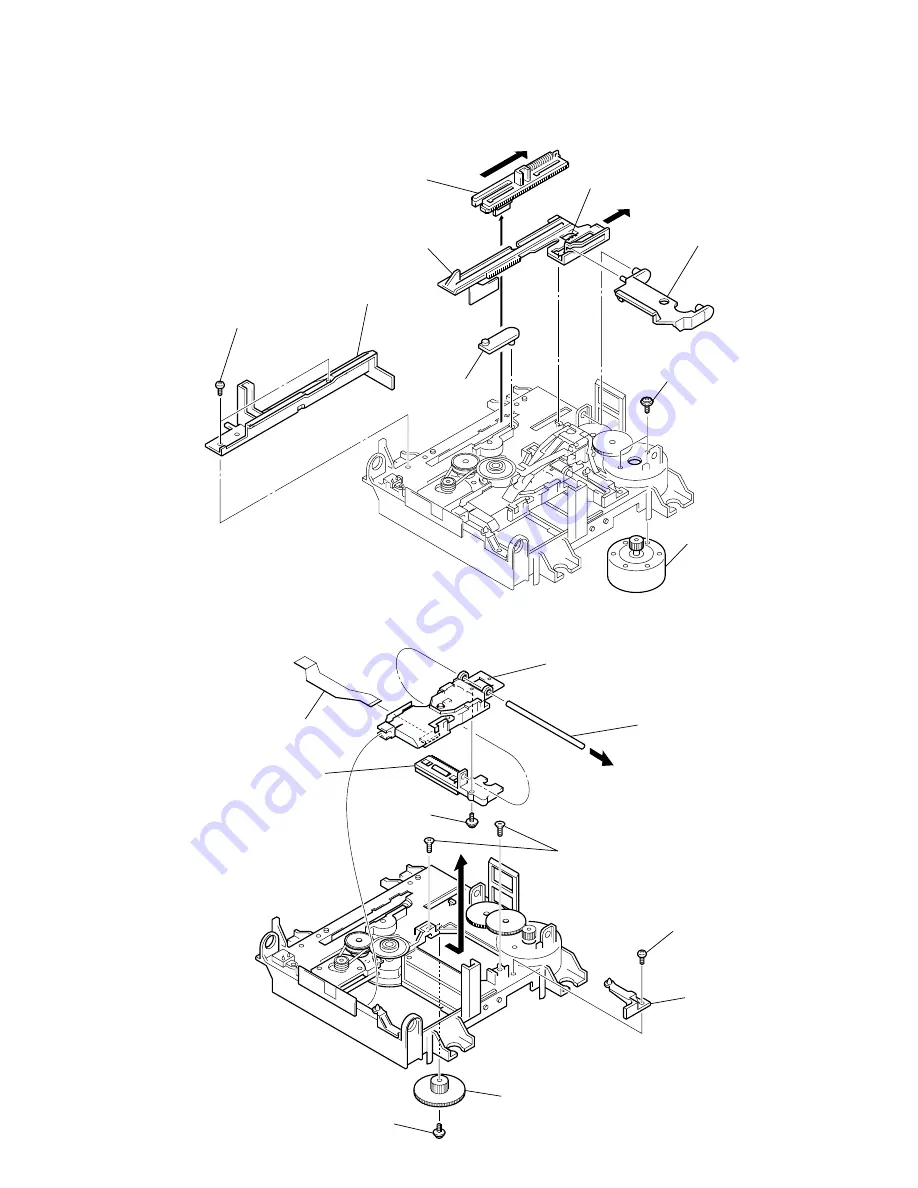

slider (EJ)

6

slider

7

lever (CHG)

8

lever (head)

3

5

A

1

two screws

(BTP 2x6)

2

guide (L)

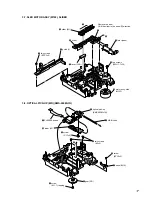

0

motor assy, sled

(M102)

9

two screws

(PWH 1.7x2.5)

Remeve the claw.

Shift the slider in the arrow

A

direction.

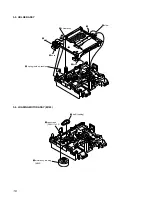

2

screw

(M 1.7), tapping

3

gear (SD)

6

two screws

(K 2x6)

7

MAIN shaft

8

4

screw

(BTP 2x6)

9

screw

(P 1.7x6)

0

slider (SL)

qa

optical pick-up

(KMS-260B/J1N)

5

base (BU-A)

1

FLEXBLE boaed

3-7. SLED MOTOR ASSY (M102), SLIDER

3-8. OPTICAL PICK-UP (MD) (KMS-260B/JIN)