25

MDS-S9

9. Press the

[YES]

button to display “EFB =

MO-P”.

Then, the optical pick-up moves to the pit area automatically

and servo is imposed.

10. Observe the waveform of the oscilloscope, and check that the

specified value is satisfied. Do not turn the

[ AMS ]

knob.

Traverse Waveform

11. Press the

[YES]

button to display “EF MO CHECK” (C14).

The disc stops rotating automatically.

12. Press the

Z

button and take out the disc.

13. Load the check disc (TDYS-1).

14. Turn the

[ AMS ]

knob to display “EF CD CHECK”

(C15).

15. Press the

[YES]

button to display “EFB =

CD”. Servo is

imposed automatically.

16. Observe the waveform of the oscilloscope, and check that the

specified value is satisfied. Do not turn the

[ AMS ]

knob.

Traverse Waveform

17. Press the

[YES]

button to display “EF CD CHECK” (C15).

18. Press the

Z

button and take out the check disc (TDYS-1).

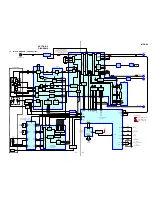

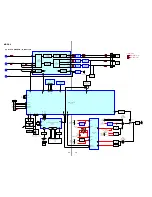

Checking Location: BD board (see page 30)

5-7-7. Focus Bias Check

Change the focus bias and check the focus tolerance amount.

Procedure:

1. Load the test disc (MDW-74/GA-1).

2. Turn the

[ AMS ]

knob to display “CPLAY1MODE”

(C34).

3. Press the

[YES]

button to display “CPLAY1MID”.

4. Press the

[MENU/NO]

button when “C =

AD =

)” is

displayed.

5. Turn the

[ AMS ]

knob to display “FBIAS CHECK”

(C16).

6. Press the

[YES]

button to display “

/

c =

”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [c =] indicate

the focus bias value.

Check that the C1 error is below 20 and ADER is below 2.

7. Press the

[YES]

button to display “

/

b =

”.

Check that the C1 error is about 100 and ADER is below 2.

8. Press the

[YES]

button to display “

/

a =

”.

Check that the C1 error is about 100 and ADER is below 2.

9. Press the

[MENU/NO]

button, then press the

Z

button and take

out the test disc (MDW-74/GA-1).

5-7-8. C PLAY Check

MO Error Rate Check

Procedure:

1. Load the test disc (MDW-74/GA-1).

2. Turn the

[ AMS ]

knob to display “CPLAY1MODE”

(C34).

3. Press the

[YES]

button to display “CPLAY1MID”.

4. The display changes to “C =

AD =

)”.

5. If the C1 error rate is below 20, check that ADER is 00.

6. Press the

[MENU/NO]

button to stop playback, then press

the

Z

button and take out the test disc (MDW-74/GA-1).

CD Error Rate Check

Procedure:

1. Load the check disc (TDYS-1).

2. Turn the

[ AMS ]

knob to display “CPLAY1MODE”

(C34).

3. Press the

[YES]

button to display “CPLAY1MID”.

4. The display changes to “C =

AD =

)”.

5. Check that the C1 error rate is below 20.

6. Press the

[MENU/NO]

button to stop playback, then press

the

Z

button and take out the check disc (TDYS-1).

5-7-9. Self-Recording/playback Check

Prepare a continuous recording disc using the unit to be repaired

and check the error rate.

Procedure:

1. Load a recordable disc (blank disc).

2. Turn the

[ AMS ]

knob to display “CREC 1MODE”

(C35).

3. Press the

[YES]

button to display “CREC 1MID”.

4. When recording starts, lights up “

REC

” and display “CREC

1 (@@@@)” (@@@@ is the address).

5. About 1 minute later, press the

[MENU/NO]

button to stop

continuous recording.

6. Turn the

[ AMS ]

knob to display “CPLAY1MODE”

(C34).

7. Press the

[YES]

button to display “CPLAY1MID”.

8. “C =

AD =

)” will be displayed.

9. Check that the C1 error becomes below 20 and the AD error

below 2.

10. Press the

[MENU/NO]

button to stop playback, then press

the

Z

button and take out the disc.

A

B

VC

Specified value : Below 10% offset value

Offset value (%) = X 100

I

A – BI

2 (A + B)

A

B

VC

Specified value : Below 10% offset value

Offset value (%) = X 100

I

A – BI

2 (A + B)

. >

. >

. >

. >

. >

. >

. >

. >

. >