MDX-M690

7

7

0

Mark

Markierung

Marques

Contrassegno di montaggio

Merkteken

Pr cautions

• Choisissez soigneusement l’emplacement de l’installation

afin que l’appareil ne gêne pas la conduite normale du

véhicule.

• Evitez d’installer l’appareil dans un endroit exposé à la

poussière, à la saleté, à des vibrations excessives ou à des

températures élevées comme en plein soleil ou à

proximité de conduits de chauffage.

• Pour garantir un montage sûr, n’utilisez que le matériel

fourni.

R glage de l angle de montage

(CDX-M770/M670)

Ajustez l’inclinaison à un angle inférieur à 60°.

(MDX-M690)

Ajustez l’inclinaison à un angle inférieur à 20°.

Partie tendue de la fa ade (

4

)

Comment retirer et fixer l cran

mobile (

5

)

Avant d’installer l’appareil, retirez la façade.

5

-A Pour retirer

1 Appuyez sur la touche

(OPEN)

de l’appareil pendant

2 secondes.

la lecture du CD/MD ou la radio s’arrête et la façade

s’incline automatiquement suivant un angle de 30 degrés.

2 Retirez l’écran mobile de la façon indiquée dans

l’illustration.

Lorsque vous avez entièrement retiré l’écran mobile, la

façade se referme automatiquement.

5

-B Pour poser

Placez l’écran mobile devant l’appareil ainsi qu’il est indiqué

dans l’illustration, puis exercez une légère pression sur la

façade jusqu’à ce qu’il s’encliquette.

Exemple de montage (

6

)

Installation dans le tableau de bord

6

-

*

Remarque

Pendant l’installation de l’appareil, vérifiez que le

panneau avant de cet appareil est fermé.

Si le panneau avant est ouvert pendant l’installation et s’il

subit une force trop importante, un dysfonctionnement

risque de se produire.

Avertissement en cas d installation

dans une voiture dont le contact ne

comporte pas de position ACC

(accessoires)

Appuyez sur la touche

(OFF)

de l’appareil pendant

deux secondes pour désactiver l’affichage de

l’horloge après avoir coupé le moteur.

Si vous n’appuyez que brièvement sur

(OFF)

, l’affichage

de l’horloge ne disparaît pas, ce qui provoque la décharge

de la batterie.

Touche de r initialisation (

7

)

Quand l’installation et les raccordements sont terminés,

appuyez sur la touche de rèinitialisation avec un stylo à

bille, etc.

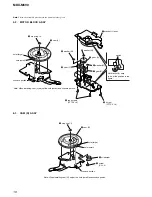

Installation du satellite de

commande (RM-X5S) (

8

)

Remarques

• Choisissez soigneusement l’endroit de montage afin que le

satellite de commande n’interfère pas avec les commandes

de la voiture.

• N’installez pas le satellite de commande dans un endroit

qui risque de compromettre la sécurité du passager avant

de quelque façon que ce soit.

• Lors de l’installation du satellite de commande, veillez à

ne pas endommager les câbles électriques, etc., situés de

l’autre côté de la surface de montage.

• Evitez d’installer le satellite de commande là où il risque

d’être soumis à des températures élevées comme sous le

rayonnement direct du soleil ou à côté d’une conduite de

chauffage, etc.

• Le commutateur de sélection Rev/Nor est situé dans la

partie inférieure du satellite de commande.

Sélectionnez “Nor” pour utiliser le satellite de commande

dans la position définie par défaut.

Sélectionnez “Rev” si vous montez le satellite de

commande du côté droit de la colonne de direction.

Conseil

Il est impossible de sélectionner Rev/Nor sur le côté de

l’appareil principal.

1 Appuyez sur les boutons et tournez les commandes

pour vérifier que l'appareil principal réagit

correctement.

Vous pouvez changer le sens des rayons IR en tournant

la molette située sur le satellite de commande.

Précaution

Assurez-vous que l’endroit où vous installez le satellite de

commande est à portée du récepteur de l’appareil.

2 Choisissez la position de montage exacte du

satellite de commande et nettoyez la surface de

montage.

Les souillures et l’huile altèrent le pouvoir adhérent de

l’adhésif double face.

3 Marquez la position pour la vis fournie.

Utilisez l’orifice de vissage du support de montage

0

pour marquer les positions.

Si vous ne parvenez pas à ajuster aisément le support de

montage

0

, découpez-le afin qu'il s'adapte à la colonne

de direction.

4 Déposez la garniture de la colonne de direction et

percez un trou de 2 mm de diamètre aux endroits

que vous avez marqués.

5 Chauffez la surface de montage et l’adhésif double

face sur le support de montage

0

à une

température comprise entre 20 °C et 30 °C et fixez

le support de montage sur la surface de montage

0

en exerçant une pression uniforme. Vissez

ensuite la vis

9

fournie.

Collez de la bande adhésive résistante, etc., de l’autre

côté de la surface de montage de manière à couvrir

l’extrémité saillante des vis de telle sorte qu’elle ne

puissent entrer en contact direct avec les câbles

électriques, etc., à l’intérieur de la colonne de direction.

6 Après avoir remonté le couvercle de la colonne de

direction, fixez le satellite de commande sur le

support de montage en alignant les quatre orifices

pratiqués à la base du satellite sur les quatre ergots

du support de montage et faites coulisser le

satellite de commande jusqu’à ce qu’il s’encliquette

dans sa position définitive comme illustré.

Précautions

• Lors de l’installation du satellite de commande près du

volant, veillez à bien fixer la courroie

qa

fournie.

• Assurez-vous que la courroie

qa

ne soit pas prise dans les

commandes du véhicule (levier de vitesses, etc.).

• Assurez-vous de bien serrer la vis de sécurité de la courroie

qa

après avoir accroché celle-ci au levier de changement

de direction, etc.

Conseil

Il existe deux orifices réservés à la courroie

qa

. Vous pouvez

utiliser indifféremment l’un ou l’autre.

Remarque

Si vous montez le satellite de commande sur la colonne de

direction, assurez-vous que l’extrémité saillante des vis à

l’intérieur de la colonne de direction n’entrave en aucune

façon le mouvement de l’axe, des organes de commande, des

commutateurs ou des câbles électriques, etc., à l’intérieur de

la colonne de direction.

Precautions

• Choose the installation location carefully so that the unit

will not interfere with normal driving operations.

• Avoid installing the unit in areas subject to dust, dirt,

excessive vibration, or high temperature, such as in direct

sunlight or near heater ducts.

• Use only the supplied mounting hardware for a safe and

secure installation.

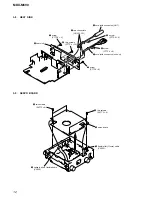

Mounting angle adjustment

(CDX-M770/M670)

Adjust the mounting angle to less than 60°.

(MDX-M690)

Adjust the mounting angle to less than 20°.

Extended portion of the front

panel (

4

)

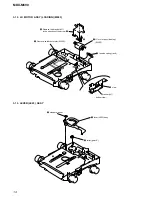

How to detach and attach the

main display window (

5

)

Before installing the unit, detach the front panel.

5

-A To detach

1 Press

(OPEN)

on the unit for 2 seconds.

CD/MD playback or radio reception stops, and the front

panel automatically tilts at an angle of 30°.

2 Detach the main display window as illustrated.

After the main display window detaching is complete,

the front panel closes automaticaly.

5

-B To attach

Place the main display window on the front side of the unit

as illustrated, then lightly push the front panel into

position until it clicks.

Mounting example (

6

)

Installation in the dashboard

6

-

*

Note

When installing this unit, be sure to close the front

panel of the unit.

If the front panel is opened while installing and given too

much force, it may cause a malfunction.

Warning when installing in a car

without ACC (accessory) position

on the ignition key switch

Be sure to press

(OFF)

on the unit for two seconds to

turn off the clock display after turning off the engine.

When you press

(OFF)

only momentarily, the clock

display does not turn off and this causes battery wear.

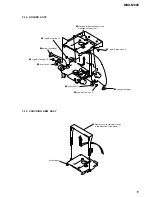

Reset button (

7

)

When the installation and connections are completed, be

sure to press the Reset button with a ballpoint pen, etc.

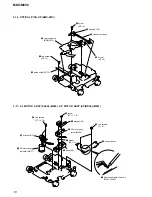

Installing the rotary commander

(RM-X5S) (

8

)

Notes

• Choose the mounting location carefully so that the rotary

commander will not interfere with operating the car.

• Do not install the rotary commander where it may

jeopardize the safety of the (front) passenger in anyway.

• When installing the rotary commander, be sure not to

damage the electrical cables etc. on the other side of the

mounting surface.

• Avoid installing the rotary commander where it may be

subject to high temperatures, such as from direct sunlight

or hot air from the heater etc.

• The Rev/Nor-select switch is located on the bottom of the

rotary commander. Select “Nor” to use the rotary

commander as the factory-set position. Select “Rev” when

you mount the rotary commander on the right side of the

steering column.

Tip

Rev/Nor cannot be selected on the side of master unit.

1 Press the buttons and rotate the controls to make

sure that your master unit reacts well.

You can change the direction of infrared rays by turning

the dial on the rotary commander.

Caution

Be sure that the place where you install the rotary

commander is within the range of receptor on the unit.

2 Choose the exact location for the rotary

commander to be mounted, then clean the

mounting surface.

Dirt or oil impair the adhesive strength of the double-

sided adhesive tape.

3 Mark position for the supplied screw.

Use the screw holes on the mounting hardware

0

to

mark the positions.

If you cannot make the mounting hardware

0

fit easy,

cut the mounting hardware

0

to fit the steering wheel

column cover.

4 Remove the steering wheel column cover, and drill

2 mm diameter hole where you have marked.

5 Warm the mounting surface and the double-sided

adhesive tape on the mounting hardware

0

to the

temperature of 20 °C to 30 °C, and attach the

mounting hardware

0

onto the mounting surface

by applying even pressure. Then screw it down

with the supplied screw

9

.

Attach a piece of heavy duty tape etc. on the other side

of the mounting surface to cover the protruding tips of

the screws so that they will not interfere with the

electrical cables etc. inside the steering wheel column.

6 After installing the steering wheel column cover,

attach the rotary commander to the mounting

hardware by aligning the four holes on the bottom

of the rotary commander to the four catches on the

mounting hardware and sliding the rotary

commander until it locks into place as illustrated.

Cautions

• Be sure to attach the supplied strap

qa

when installing the

rotary commander near the steering wheel.

• Be sure that the strap

qa

does not get caught on the car

controls (gear, shifter, etc.).

• Be sure to tighten the stopper of the strap

qa

after

hanging the strap

qa

on the indicator switch, etc.

Tip

There are two holes for the strap

qa

. You can use whichever

hole you prefer.

Note

If you are mounting the rotary commander to the steering

wheel column, make sure that the protruding tips of the

screws on the inner surface of the column do not in anyway

hinder or interfere with the movement of the rotating shaft,

operative parts of the switches or the electrical cables etc.

inside the column.

Vorsichtsma§nahmen

• Wählen Sie den Einbauort sorgfältig so aus, daß das

Gerät beim Fahren nicht hinderlich ist.

• Bauen Sie das Gerät so ein, daß es keinen hohen

Temperaturen (keinem direkten Sonnenlicht, keiner

Warmluft von der Heizung), keinem Staub, keinem

Schmutz und keinen starken Vibrationen ausgesetzt ist.

• Für eine sichere Befestigung verwenden Sie stets nur die

mitgelieferten Montageteile.

Hinweis zum Montagewinkel

(CDX-M770/M670)

Das Gerät sollte in einem Winkel von weniger als 60°

montiert werden.

(MDX-M690)

Das Gerät sollte in einem Winkel von weniger als 20°

montiert werden.

berstehender Teil der

Frontplatte (

4

)

Abnehmen und Anbringen des

Haupt-Displays (

5

)

Nehmen Sie die Frontplatte vor dem Einbau des

Geräts ab.

5

-A Abnehmen

1 Drücken Sie 2 Sekunden lang

(OPEN)

am Gerät.

Die CD/MD-Wiedergabe bzw. der Radioempfang

stoppt, und die Frontplatte wird automatisch in einem

Winkel von 30 Grad geneigt.

2 Nehmen Sie das Haupt-Display wie in der

Abbildung dargestellt ab.

Wenn das Haupt-Display abgenommen ist, schließt sich

die Frontplatte automatisch.

5

-B Anbringen

Setzen Sie das Haupt-Display wie in der Abbildung

dargestellt an die Vorderseite des Geräts an, und drücken

Sie die Frontplatte dann leicht in die richtige Position, bis

sie mit einem Klicken einrastet.

Montagebeispiel (

6

)

Installation im Armaturenbrett

6

-

*

Hinweis

Achten Sie beim Einbau des Geräts darauf, die

Frontplatte geschlossen zu halten.

Wenn sich die Frontplatte beim Einbau öffnet und Sie zu

stark darauf drücken, kann es zu einer Fehlfunktion kommen.

Warnhinweis zur Installation des

Ger ts in einem Auto mit Z ndschlo§

ohne Zubeh rposition ACC oder I

Drücken Sie am Gerät unbedingt zwei Sekunden lang

(OFF)

, um die Uhrzeitanzeige auszuschalten,

nachdem Sie den Motor ausgeschaltet haben.

Wenn Sie

(OFF)

nur kurz drücken, wird die

Uhrzeitanzeige nicht ausgeschaltet, und der Autobatterie

wird Strom entzogen.

R cksetztaste (

7

)

Nach der Installation und dem Anschluß muß die

rücksetztaste mit einem Kugelschreiber o. ä. gedrückt werden.

Installieren des Joystick

(RM-X5S) (

8

)

Hinweise

• Wählen Sie den Montageort sorgfältig aus, so daß der

Joystick beim Fahren nicht im Wege ist.

• Montieren Sie den Joystick nicht an einer Stelle, an der er

eine Gefahr für den Beifahrer auf dem Vordersitz

darstellen könnte.

• Achten Sie bei der Montage des Joystick darauf, die

Elektrokabel an der anderen Seite der Montagefläche

nicht zu beschädigen.

• Montieren Sie den Joystick nicht an einer Stelle, an der er

hohen Temperaturen, zum Beispiel direktem Sonnenlicht

oder der Warmluft aus der Wagenheizung, ausgesetzt ist.

• Der Wählschalter Rev/Nor befindet sich an der Unterseite

des Joysticks. Wählen Sie „Nor“, wenn die werkseitig

voreingestellte Drehrichtung der Regler beibehalten

werden soll. Wählen Sie „Rev“, wenn Sie den Joystick auf

der rechten Seite der Lenksäule anbringen.

Tip

Rev/Nor kann nicht mit dem Hauptgerät ausgewählt werden.

1 Drücken Sie die Tasten, drehen Sie die Regler, und

vergewissern Sie sich, daß das Hauptgerät

entsprechend reagiert.

Sie können die Richtung der Infrarotstrahlen ändern,

indem Sie den Regler am Joystick drehen.

Vorsicht

Vergewissern Sie sich, daß der Montageort des Joysticks

innerhalb der Reichweite des Empfängers am Gerät ist.

2 Wählen Sie die Stelle aus, an der Sie den Joystick

montieren wollen, und reinigen Sie dann die

Montagefläche.

Staub oder Fettspuren beeinträchtigen die Haftung des

doppelseitigen Klebebandes.

3 Markieren Sie die Stelle zum Anbringen der

mitgelieferten Schraube.

Verwenden Sie dazu die Bohrung im Montageteil

0

.

Wenn das Montageteil

0

nicht auf die Abdeckung der

Lenkradsäule paßt, schneiden Sie es bitte zurecht.

4 Nehmen Sie die Abdeckung der Lenkradsäule ab,

und bohren Sie an der Stelle, die Sie gerade

markiert haben, ein Loch von 2 mm Durchmesser.

5 Erwärmen Sie die Montagestelle und das

doppelseitige Klebeband am Montageteil

0

auf

eine Temperatur von 20 bis 30 °C, und drücken Sie

dann das Montageteil

0

mit gleichmäßigem Druck

auf die Montagestelle. Befestigen Sie es dann mit

der mitgelieferten Schraube

9

.

Bringen Sie ein Stück sehr festes Klebeband o. ä. an der

Gegenseite der Montagefläche an, um die vorstehenden

Spitzen der Schrauben abzudecken, damit diese nicht

die Elektrokabel in der Lenkradsäule beschädigen

können.

6 Bringen Sie nun die Abdeckung der Lenkradsäule

wieder an, und befestigen Sie dann den Joystick

auf dem Montageteil, indem Sie die vier

Aussparungen an der Unterseite des Joysticks an

den vier Haken auf dem Montageteil ausrichten

und den Joystick daraufschieben, bis er einrastet,

wie auf der Abbildung zu sehen.

Vorsicht

• Achten Sie darauf, den mitgelieferten Riemen

qa

anzubringen, wenn Sie den Joystick in der Nähe des

Lenkrades installieren.

• Achten Sie darauf, daß sich der Riemen

qa

nicht an

Bedienelementen des Fahrzeugs verfängt (Schalthebel,

Handbremse usw.).

• Achten Sie darauf, den Stopper des Riemens

qa

anzuziehen, nachdem Sie den Riemen

qa

an den

Blinkerhebel o. ä. gehängt haben.

Tip

Für den Riemen

qa

sind zwei Aussparungen vorhanden. Sie

können sie nach Belieben auswählen.

Hinweis

Wenn Sie den Joystick an der Lenkradsäule montieren,

achten Sie darauf, daß die vorstehenden Spitzen der

Schrauben an der Innenfläche der Lenkradsäule die

Bewegung der Lenkwelle, die Funktionsteile der Schalter

bzw. die Elektrokabel innerhalb der Lenkradsäule in keiner

Weise behindern.

Voorzorgsmaatregelen

• Kies de installatieplaats zorgvuldig zodat het toestel de

bestuurder niet hindert tijdens het rijden.

• Installeer het apparaat niet op plaatsen waar het

blootgesteld wordt aan hoge temperaturen, b.v. in direct

zonlicht of bij de warme luchtstroom van de

autoverwarming, aan sterke trillingen, of waar het in

contact komt met veel stof of vuil.

• Gebruik voor het veilig en stevig monteren van het

apparaat uitsluitend de bijgeleverde montage-

onderdelen.

Maximale montagehoek

(CDX-M770/M670)

Installeer het apparaat nooit onder een hoek van meer

dan 60° met het horizontale vlak.

(MDX-M690)

Installeer het apparaat nooit onder een hoek van meer

dan 20° met het horizontale vlak.

Verlengstuk van het frontpaneel

(

4

)

Het hoofddisplay losmaken en

bevestigen (

5

)

Verwijder, alvorens met het installeren te beginnen,

het afneembare voorpaneel.

5

-A Verwijderen

1 Hou

(OPEN)

op het toestel 2 seconden ingedrukt.

CD/MD-weergave of radio-ontvangst stopt en het

frontpaneel kantelt automatisch in een hoek van 30

graden.

2 Maak het hoofddisplay los zoals de afbeelding laat

zien.

Nadat het hoofddisplay volledig is losgemaakt, sluit het

frontpaneel automatisch.

5

-B Bevestigen

Plaats het hoofddisplay vooraan op het toestel zoals de

afbeelding laat zien en druk het vervolgens lichtjes op zijn

plaats tot het vastklikt.

Montagevoorbeeld (

6

)

Montage in het dashboard

6

-

*

Opmerking

Bij het installeren van het toestel dient het

frontpaneel te zijn gesloten.

Als het frontpaneel tijdens het installeren open is, kan het

worden geforceerd wat tot een defect kan leiden.

Opgelet bij het monteren in een auto

waarvan het contactslot geen ACC

(accessory) stand heeft

Druk

(OFF)

op het toestel gedurende twee seconden

in om de klokweergave uit te schakelen na het

afzetten van de motor.

Indien u slechts even op

(OFF)

drukt, verdwijnt de

tijdindicatie niet waardoor de batterij uitgeput raakt.

Terustelknop (

7

)

Druk, nadat u het apparaat heeft geïnstalleerd en de

aansluitingen heeft gemaakt, met een balpen of een ander

puntig voorwerp op de terustelknop.

Installatie van de

bedieningssatelliet (RM-X5S) (

8

)

Opmerkingen

• Ga zorgvuldig te werk bij het kiezen van een geschikte

montagepositie zodat de bedieningssatelliet u nooit

hindert bij het rijden.

• Installeer de bedieningssatelliet nooit op een plaats waar

hij de veiligheid van de (voor)passagier in gevaar kan

brengen.

• Bij het installeren van de bedieningssatelliet moet u erop

letten dat u de elektrische bedrading en dergelijke aan de

andere kant van het montagevlak niet beschadigt.

• Installeer de bedieningssatelliet niet op plaatsen waar hij

blootstaat aan hoge temperaturen, bijvoorbeeld door

rechtstreekse zonnestraling of warme lucht afkomstig van

de verwarming, enz.

• De Rev/Nor-keuzeschakelaar bevindt zich onderaan op de

bedieningssatelliet.

Kies “Nor” om de bedieningssatelliet te gebruiken met de

fabrieksinstelling.

Kies “Rev” wanneer u de bedieningssatelliet rechts op de

stuurkolom monteert.

Tip

Rev/Nor kan niet worden geselecteerd op het

hoofdtoestel.

1 Druk op de toetsen en draai aan de regelaars om

zeker te zijn dat uw master unit goed functioneert.

U kunt de richting van de infraroodstralen wijzigen

door aan de knop op de bedieningssatelliet te draaien.

Let op!

Zorg ervoor dat u de bedieningssatelliet installeert

binnen het ontvangstbereik van het toestel.

2 Kies de exacte installatieplaats voor de

bedieningssatelliet en maak vervolgens het

montagevlak schoon.

Vuil of vet tasten het kleefvermogen van het

dubbelzijdige plakband aan.

3 Markeer een bevestigingspunt voor de

meegeleverde schroef.

Markeer de posities aan de hand van de schroefgaten

in het bevestigingselement

0

.

Als het bevestigingselement

0

niet goed past, moet u

het overtollige gedeelte afsnijden zodat het wel in de

stuurkolombekleding past.

4 Verwijder de stuurkolombekleding en boor een gat

van 2 mm op de gemarkeerde posities.

5 Warm het bevestigingsvlak en de dubbelzijdige

kleefband op het bevestigingselement

0

op tot

een temperatuur van 20 à 30 °C en plaats de steun

op het bevestigingsvlak door gelijkmatig aan te

drukken. Schroef hem vervolgens vast met de

meegeleverde schroef

9

.

Breng een stuk tape of iets dergelijks aan op de andere

kant van het bevestigingsvlak om te voorkomen dat de

uitstekende schroefpunten in contact komen met de

elektrische bedrading en dergelijke binnenin de

stuurkolom.

6 Plaats de stuurkolombekleding terug en bevestig

de bedieningssatelliet op het montage-accessoire

door de vier gaten onderaan de bedieningssatelliet

te laten samenvallen met de vier

bevestigingsklemmen op het montage-accessoire

en verschuif de bedieningssatelliet tot hij op zijn

plaats klikt zoals de illustratie laat zien.

Let op!

• Bevestig de meegeleverde riem

qa

wanneer u de

bedieningssatelliet in de buurt van het stuurwiel

monteert.

• Zorg ervoor dat riem

qa

niet kan verstrikt raken in de

bedieningselementen van de auto (schakelpook enz).

• Zet de stopper op de riem

qa

vast nadat u deze hebt

bevestigd aan de richtingaanwijzerhendel enz

Tip

Er zijn twee gaten voor riem

qa

. U kunt kiezen welk ervan

u gebruikt.

Opmerking

Bij het monteren van de bedieningssatelliet op de

stuurkolom, moet u ervoor zorgen dat de uitstekende

punten van de schroeven aan de binnenkant van de

stuurkolom de stuurstang, schakelaars, elektrische

bedrading, enzovoort in de stuurkolom niet hinderen.

Precauzioni

• Scegliere con attenzione la posizione per l’installazione in

modo che l’apparecchio non interferisca con le operazioni

di guida del conducente.

• Evitare di installare l’apparecchio dove sia soggetto ad

alte temperature, come alla luce solare diretta o al getto di

aria calda dell’impianto di riscaldamento, o dove possa

essere soggetto a polvere, sporco e vibrazioni eccessive.

• Usare solo il materiale di montaggio in dotazione per

un’installazione stabile e sicura.

Regolazione dell angolo di montaggio

(CDX-M770/M670)

Regolare l’angolo di montaggio in modo che sia inferiore a 60°.

(MDX-M690)

Regolare l’angolo di montaggio in modo che sia inferiore a 20°.

parte sporgente del pannello

anteriore (

4

)

Come rimuovere e applicare la

finestra del display principale (

5

)

Prima di installare l’apparecchio rimuovere il pannello

anteriore.

5

-A Per rimuoverlo

1 Premere

(OPEN)

sull’apparecchio per 2 secondi.

la riproduzione di CD/MD o la ricezione radio si

arresta, quindi il pannello anteriore si inclina

automaticamente di 30 gradi.

2 Rimuovere la finestra del display principale, come

illustrato.

Una volta completata la rimozione della finestra del

display principale, il pannello anteriore si chiude

automaticamente.

5

-B Per reinserirlo

Posizionare la finestra del display principale sul lato

anteriore dell’apparecchio come illustrato, quindi spingere

il pannello anteriore evitando di esercitare eccessiva

pressione fino a quando non scatta in posizione.

Esempio di montaggio (

6

)

Installazione nel cruscotto

6

-

*

Nota

Durante l’installazione dell’apparecchio, assicurarsi

di chiudere il relativo pannello anteriore.

Se durante l’installazione il pannello anteriore è aperto e

viene esercitata eccessiva forza, è possibile che si

verifichino problemi di funzionamento.

Informazioni importanti per quando

si effettua l installazione su un auto

sprovvista della posizione ACC

sull interruttore di accensione

Assicurarsi di premere

(OFF)

sull’apparecchio per due

secondi per spegnere il display dell’orologio dopo che

il motore è stato spento.

Se si preme

(OFF)

solo per un attimo, il display

dell’orologio non si spegne causando in questo modo lo

scaricamento della batteria.

Tasto di azzeramento (

7

)

Dopo avere terminato l’installazione e i collegamenti,

assicurarsi di premere il tasto di azzeramento con la punta

di una penna a sfera, ecc.

Installazione del telecomando a

rotazione (RM-X5S) (

8

)

Note

• Scegliere attentamente la posizione di montaggio in modo

che il telecomando a rotazione non interferisca con la guida.

• Non installare il telecomando a rotazione in posizione tale

da poter compromettere in alcun modo la sicurezza del

passeggero.

• Al momento di installare il telecomando a rotazione

assicurarsi di non danneggiare i cavi elettrici ecc. nella parte

posteriore della superficie di montaggio.

• Non installare il telecomando a rotazione in posizione

soggetta ad alte temperature, ad esempio esposto alla luce

solare diretta o al calore proveniente dall’impianto di

riscaldamento della vettura.

• L’interruttore di selezione Rev/Nor è situato nella parte

inferiore del telecomando a rotazione.

Selezionare “Nor” per utilizzare il telecomando a rotazione

con le impostazioni di fabbrica. Selezionare “Rev” quando il

telecomando a rotazione viene montato sul lato destro del

piantone di guida.

Suggerimento

Non è possibile selezionare Rev/Nor dall’unità principale.

1 Premere i tasti e ruotare i comandi per verificare che

l'apparecchio principale funzioni correttamente.

È possibile cambiare la direzione dei raggi infrarossi

ruotando la manopola sul telecomando a rotazione.

Attenzion

Assicurarsi che il luogo in cui viene installato il telecomando

a rotazione sia all’interno della gamma del ricettore

dell’unità principale.

2 Scegliere la posizione esatta di montaggio del

telecomando a rotazione, quindi pulire la superficie

di montaggio.

La sporcizia o l’unto possono pregiudicare la tenuta del

nastro biadesivo.

3 Segnare la posizione di montaggio per la vite in

dotazione.

Usare il foro per la vite sulla staffa di montaggio

0

per

segnare la posizione.

Se non è possibile installare la staffa di montaggio

0

facilmente; tagliare la staffa di montaggio

0

per

adattarla alla copertura del piantone di guida.

4 Rimuovere il coperchio della colonna del volante e

praticare un foro di 2 mm di diametro nella

posizione contrassegnata.

5 Riscaldare la superficie di montaggio e il nastro

biadesivo sulla staffa di montaggio

0

ad una

temperatura compresa tra 20 °C e 30 °C. Applicare

la staffa di montaggio

0

sulla superficie di

montaggio esercitando una pressione omogenea,

quindi fissarla avvitando la vite

9

in dotazione.

Applicare una striscia di nastro adesivo pesante sull’altro

lato della superficie di montaggio in modo da coprire la

punta sporgente delle viti perché queste non interferiscano

con i cavi elettrici all’interno della colonna del volante.

6 Dopo aver rimontato il coperchio della colonna del

volante, montare il telecomando allineando i

quattro fori sul fondo del comando ai quattro fermi

sulla staffa di montaggio e facendo scorrere il

telecomando fino a che non si blocca in posizione,

come illustrato in figura.

Attenzione

• Assicurarsi di inserire il cordino

qa

in dotazione quando si

installa il telecomando a rotazione vicino al volante.

• Assicurarsi che il cordino

qa

non rimanga incastrato tra i

comandi dell’automobile (cambio, pedali, ecc.).

• Assicurarsi di stringere il fermo del cordino

qa

dopo aver

applicato il cordino

qa

all’interruttore dell’indicatore e così

via.

Suggerimento

Esistono due fori per il cordino

qa

.

Utilizzare indifferentemente uno dei due.

Nota

Se il telecomando viene montato sulla colonna del volante,

assicurarsi che le punte sporgenti delle viti sulla superficie

interna della colonna non pregiudichino o interferiscano in

alcun modo con il movimento dell’albero, con i componenti

degli interruttori o con i cavi elettrici etc. all’interno della

colonna.

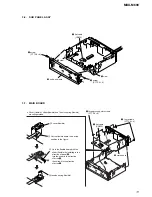

1

Dashboard

Armaturenbrett

Tableau de bord

Cruscotto

Dashboard

Fire wall

Motorraumtrennwand

Paroi ignifuge

Parete tagliafiamma

Brandschot

Bend these claws outward for a tight fit, if

necessary.

Falls erforderlich, diese Klammern für einen

sicheren Halt hochbiegen.

Pliez ces griffes pour assurer une prise

correcte si nécessaire.

Piegare questi morsetti per un‘installazione

più sicura, se necessario.

Indien nodig kunt u deze lipjes ombuigen

voor een steviger bevestiging.

7

7

5

7

5

5

4

2

3

1

1

5

6

A

B

2

3

4

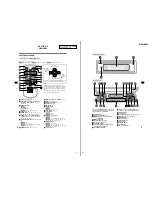

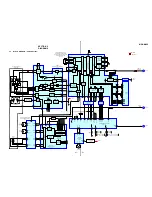

Power connection diagram

Auxiliary power connector may vary depending on the

car. Check your car’s auxiliary power connector diagram

to make sure the connections match correctly. There are

three basic types (illustrated below). You may need to

switch the positions of the red and yellow leads in the car

stereo’s power connecting cord.

After matching the connections and switched power

supply leads correctly, connect the unit to the car’s power

supply. If you have any questions and problems

connecting your unit that are not covered in this manual,

please consult the car dealer.

Stromanschlu§diagramm

Der Hilfsstromanschluß kann je nach Fahrzeugtyp

unterschiedlich sein. Sehen Sie im

Hilfsstromanschlußdiagramm für Ihr Fahrzeug nach, wie

die Verbindung ordnungsgemäß vorgenommen werden

muß. Es gibt, wie unten abgebildet, drei grundlegende

Typen. Sie müssen möglicherweise die rote und gelbe

Leitung des Stromversorgungskabels der

Autostereoanlage vertauschen.

Stellen Sie die Anschlüsse her, schließen Sie die

geschalteten Stromversorgungsleitungen richtig an, und

verbinden Sie dann das Gerät mit der Stromversorgung

Ihres Fahrzeugs. Wenn beim Anschließen des Geräts

Fragen oder Probleme auftreten, die in dieser

Bedienungsanleitung nicht erläutert werden, wenden Sie

sich bitte an den Autohändler.

Sch ma de connexion

d alimentation

Le connecteur d’alimentation auxiliaire peut varier

suivant le type de voiture. Vérifiez le schéma du

connecteur d’alimentation auxiliaire de votre voiture

pour vous assurer que les connexions correspondent. Il

en existe trois types de base (illustrés ci-dessous). Il se

peut que vous deviez commuter la position du fil rouge

et jaune du cordon d’alimentation de l’autoradio.

Après avoir établi les connexions et commuté

correctement les fils d’alimentation, raccordez l’appareil à

l’alimentation de la voiture. Si vous avez des questions

ou des difficultés à propos de cet appareil qui ne sont pas

abordées dans le présent mode d’emploi, consultez votre

revendeur automobile.

Auxiliary power connector

Hilfsstromanschluß

Connecteur d’alimentation auxiliaire

Connettore di alimentazione ausiliare

Hulpvoedingsaansluiting

4

Yellow

Gelb

Jaune

Giallo

Geel

continuous power supply

permanente Stromversorgung

alimentation continue

alimentazione continua

continu voeding

the car without ACC position

Fahrzeug ohne Zubehörposition (ACC)

Voiture sans position ACC

la macchina senza posizione ACC

Wagen zonder ACC stand

Red

Rot

Rouge

Rosso

Rood

Red

Rot

Rouge

Rosso

Rood

Yellow

Gelb

Jaune

Giallo

Geel

Yellow

Gelb

Jaune

Giallo

Geel

Red

Rot

Rouge

Rosso

Rood

switched power supply

geschaltete Stromversorgung

alimentation commutée

alimentazione commutata

geschakelde voeding

7

4

Yellow

Gelb

Jaune

Giallo

Geel

switched power supply

geschaltete Stromversorgung

alimentation commutée

alimentazione commutata

geschakelde voeding

Red

Rot

Rouge

Rosso

Rood

Red

Rot

Rouge

Rosso

Rood

Yellow

Gelb

Jaune

Giallo

Geel

Yellow

Gelb

Jaune

Giallo

Geel

Red

Rot

Rouge

Rosso

Rood

continuous power supply

permanente Stromversorgung

alimentation continue

alimentazione continua

continu voeding

7

Red

Rot

Rouge

Rosso

Rood

Red

Rot

Rouge

Rosso

Rood

Yellow

Gelb

Jaune

Giallo

Geel

Yellow

Gelb

Jaune

Giallo

Geel

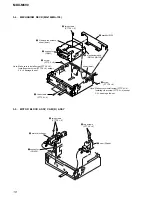

8

2

3

4

1

Infrared rays dial

Regler für Infrarotstrahlen

Molette de réglage des rayons IR

Manopola raggi infrarossi

Knop infraroodstralen

5

0

9

6

Heavy duty tape etc.

Sehr festes Klebeband o. ä.

Bande adhésive résistante, etc.

Nastro adesivo pesante.

Sterke kleefband of dergelijke

the other hole

die andere Aussparung

l’autre orifice

altro foro

ander gat

Holes

Aussparungen

Orifices

Fori

Gaten

qa

qa

Diagramma dei collegamenti di

alimentazione

Il connettore di alimentazione ausiliaria può variare a

seconda della macchina. Controllare il diagramma del

connettore di alimentazione ausiliaria della macchina per

essere sicuri che le connessioni corrispondano

correttamente. Vi sono tre tipi di base (illustrazione

sotto). Potrà essere necessario cambiare le posizioni dei

conduttori rosso e giallo nel cavo di alimentazione dello

stereo della macchina.

Dopo aver fatto corrispondere le connessioni e i cavi di

alimentazione commutata, collegare l’apparecchio

all’alimentazione della macchina. Se si hanno domande o

se sorgono problemi che non sono stati trattati nel

manuale nel collegare l’apparecchio, contattare

l’autoconcessionario.

Voedingsaansluitschema

De hulpvoedingsaansluiting kan verschillen naargelang

van de wagen. Controleer het voedingsaansluitschema

dat bij dit toestel wordt geleverd om te zien of de

aansluitingen kloppen. Er zijn drie basistypes (zie

illustratie hieronder).

Als de aansluitingen en geschakelde voedingskabels

kloppen, sluit u het toestel aan op de voeding van de

wagen. Indien u nog vragen of problemen hebt in

verband met het aansluiten van het toestel die niet in

deze handleiding vermeld staan, raadpleeg dan de

autodealer.

7

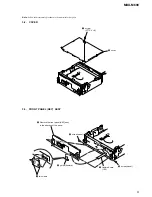

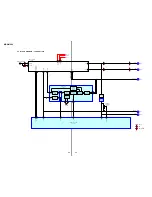

Mounting example

Montagebeispiel

Exemple de montage

Rev

Nor

Extended portion of the front panel

Überstehender Teil der Frontplatte

Partie étendue de la façade

Parte sporgente del pannello anteriore

Verlengstuk van het frontpaneel

7 mm

20 mm

4

(OPEN)

c

Esempio di montaggio

Montagevoorbeeld

*

Summary of Contents for MDX-M690

Page 79: ...79 MDX M690 MEMO ...